High-efficiency distribution network branch wiring live-line robot

A live working, high-efficiency technology, applied in the field of robotics, can solve problems such as low efficiency and poor branch line safety, and achieve the effects of simple and flexible deployment, high work efficiency, and improved reliability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

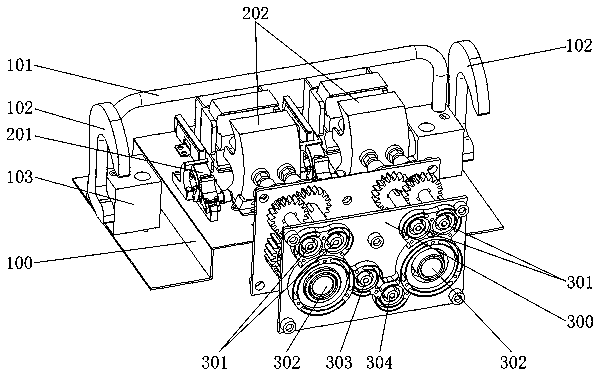

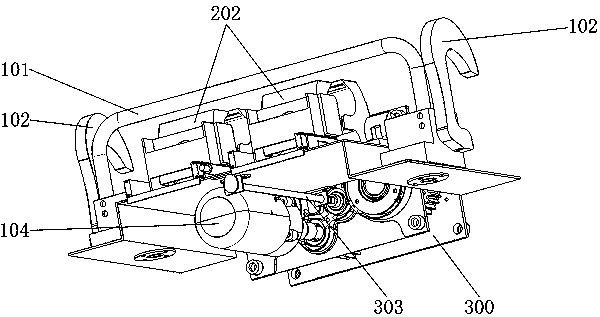

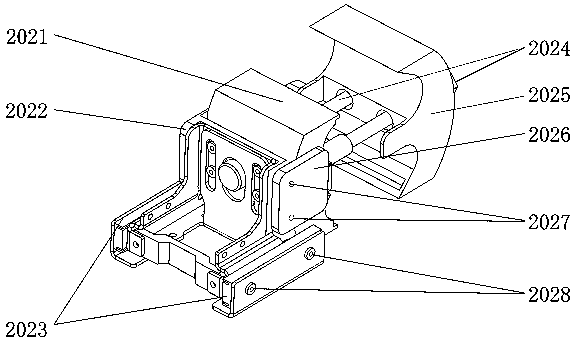

[0022] A high-efficiency distribution network connected branch line live working robot, such as figure 1 As shown, this embodiment includes a chassis 100, a boom 101, a hanging arm 102, a swinging arm drive 103, a clamp seat, a clamp tightening device, a camera and a remote controller, a boom 101, a swinging arm drive 103 and a clamp The seats are all installed on the chassis 100, and the branch wire clamp 201 is installed on the chassis 100, which is used to limit the extension direction of the branch wire and avoid wire entanglement. The chassis 100 is processed with a protrusion 105, and the bottom of the fixed clamp block 2025 is processed with a protrusion 105 abutting groove. The hanging arm 102 is installed on the swinging drive 103 of the hanging arm. There are two wire clip seats arranged side by side along the extension direction of the target wire. The puncture wire clips 202 are installed on the two wire clip seats, and the target wire passes through. The puncture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com