Improved impact head for shock absorber of aluminum die casting spraying machine

A shock absorber and sprayer technology, applied in the field of metal casting, can solve problems such as high friction, wear, and increased maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

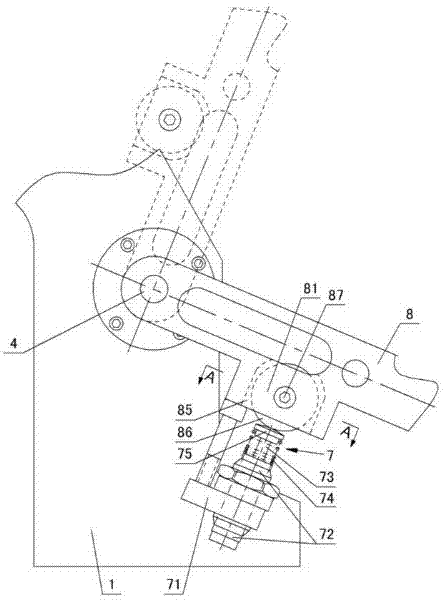

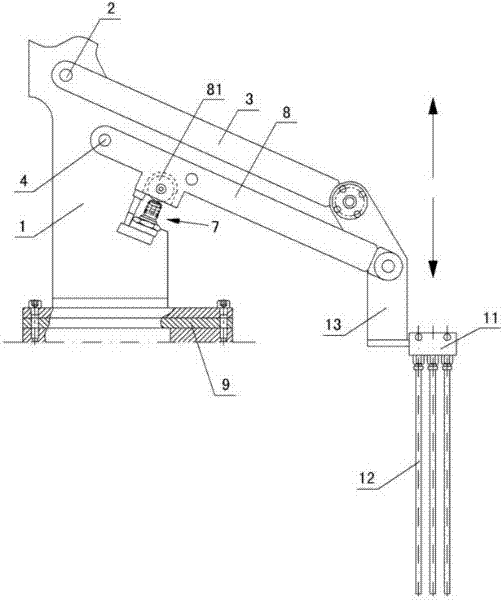

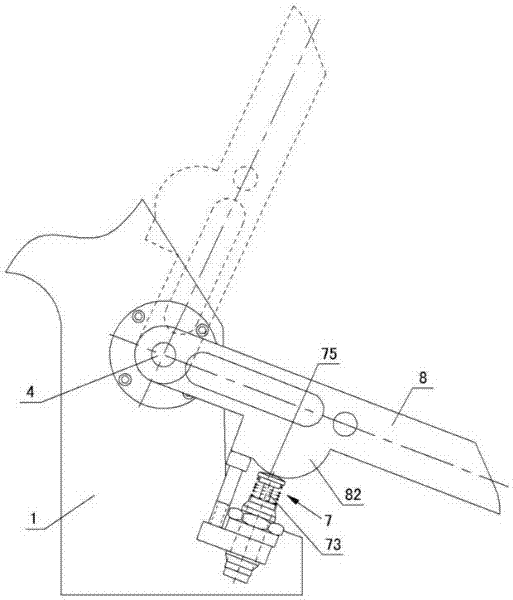

[0011] The invention relates to an improved bumper for the shock absorber of an aluminum die-casting mold sprayer, such as Figure 1-Figure 4 As shown, it includes an aluminum die-casting machine bracket mount 9, the bracket mount is connected to the spray machine base 1 and the sprayer assembly 11, the sprayer assembly is connected to the spray pipe 12 and the power bracket 13, the power bracket is driven by the cylinder, and the power bracket 13 is connected to the power bracket 13. The long left and right arms 3 are connected to one end of the short left and right arms 8, and the other ends of the long left and right arms 3 and the short left and right arms 8 are connected to the sprayer box base 1 through the rotating shafts 2 and 4, and a shock absorber is installed under the sprayer box base 1 7. The shock absorber 7 includes a body support 71, a shock absorber body 72 installed on the body support 71, a shock absorber body with a buffer rod 73, and the head of the buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com