non-slip wrench

A wrench and slider technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of mismatching nut model and wrench model, damage to the outer edges and corners of bolts or nuts, and inability to complete nut tightening or loosening. The effect of easy one-hand operation, good fluidity and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

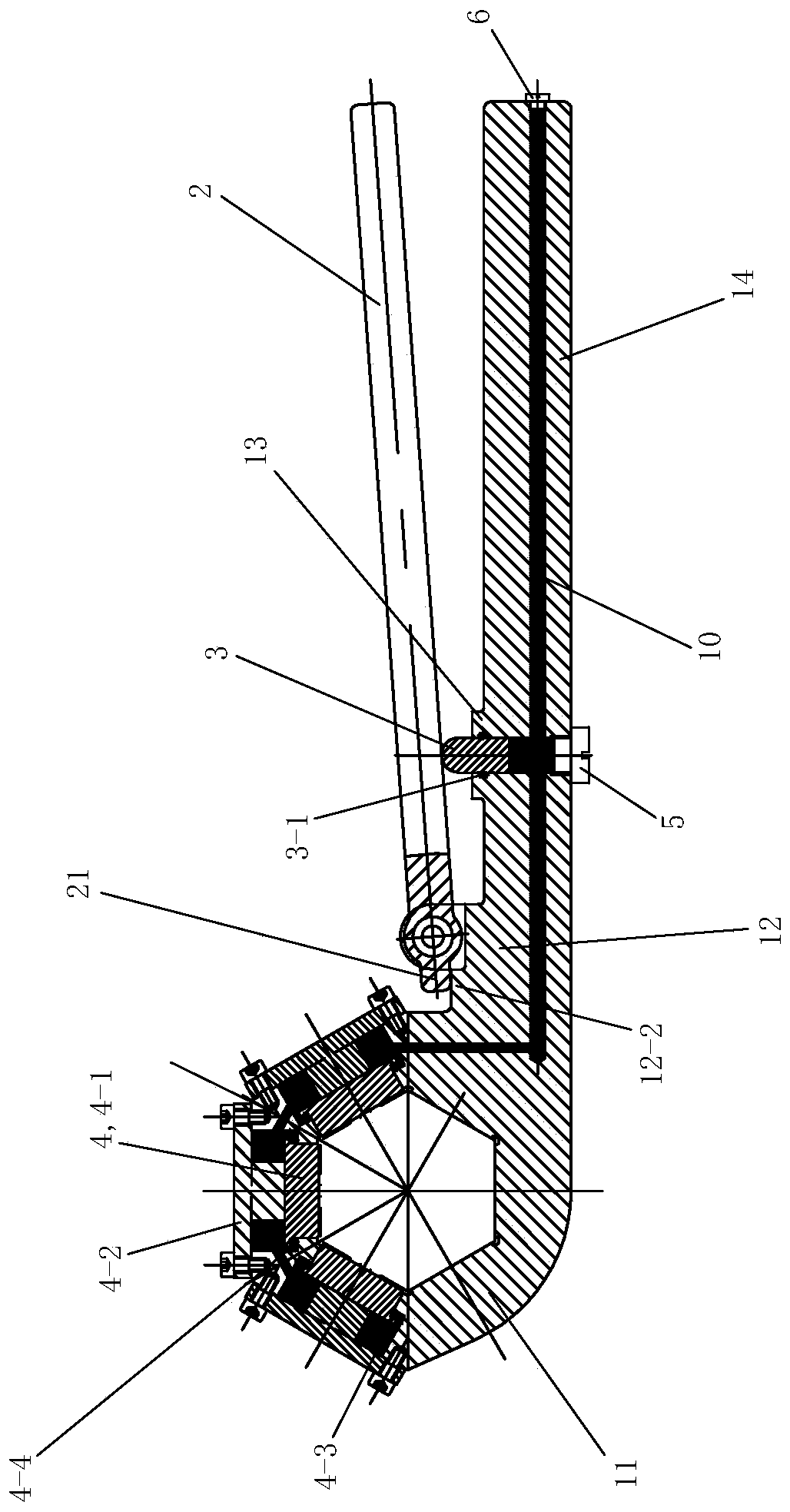

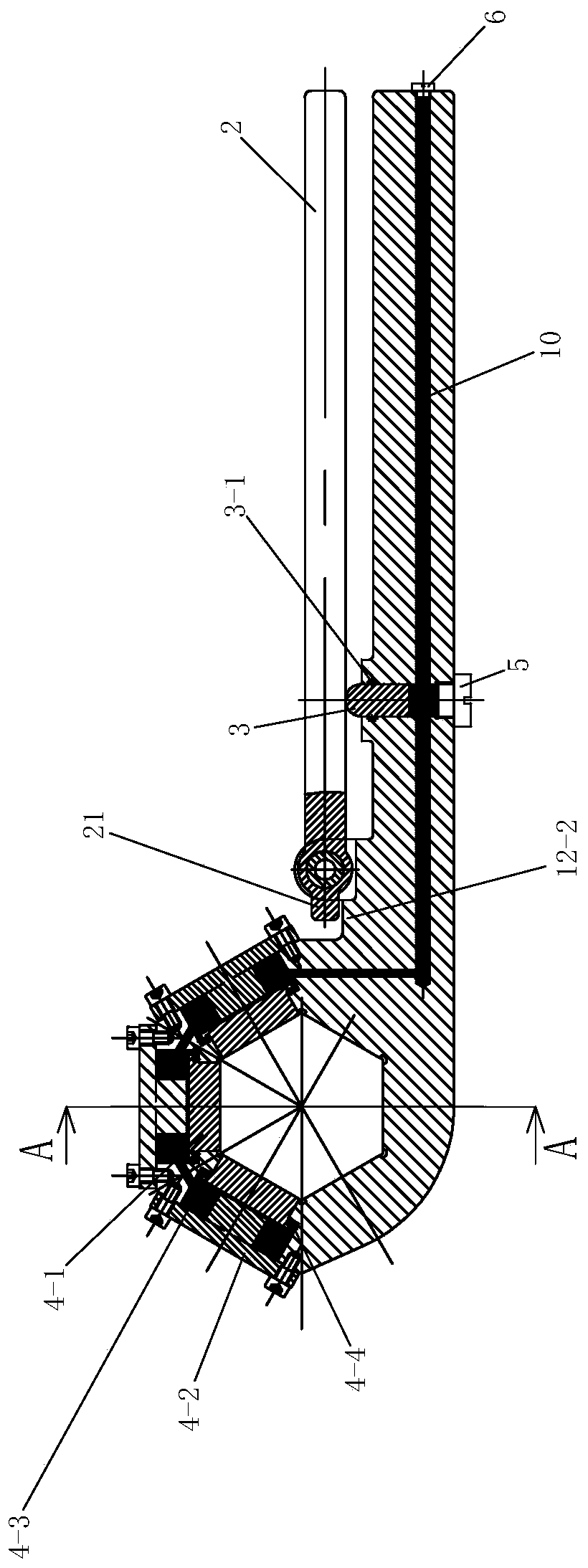

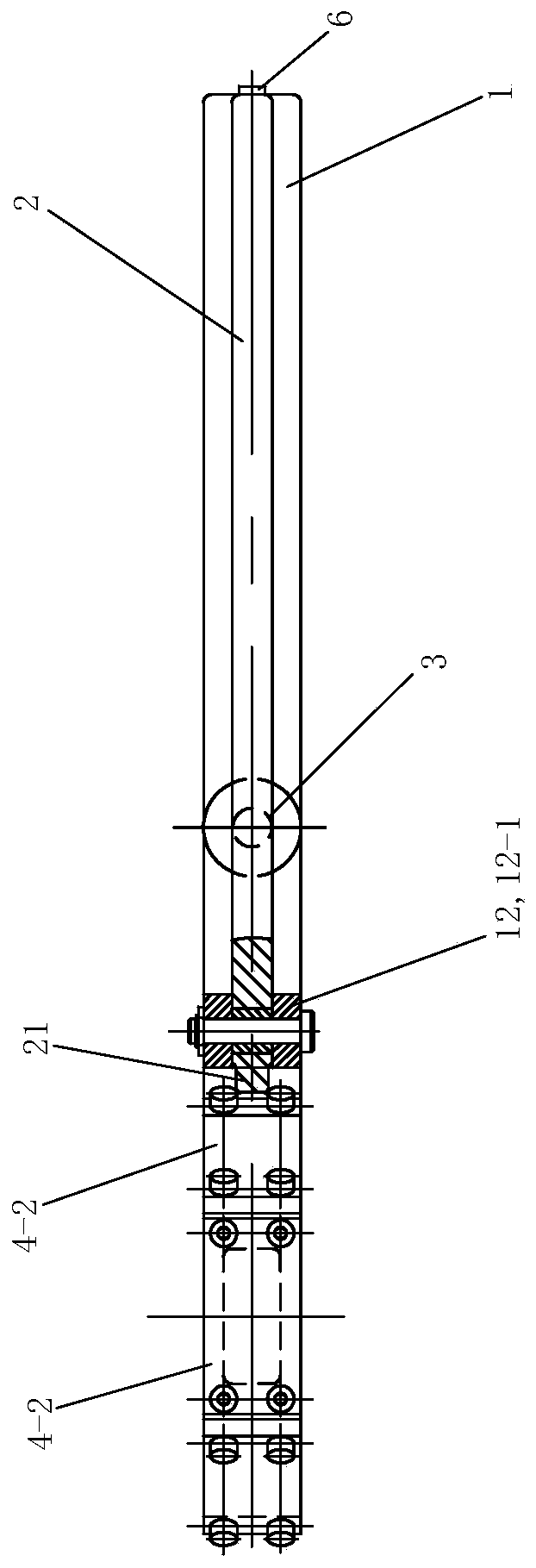

[0048] The description of the invention follows figure 1 Describe the specific orientation shown, figure 1 The up, down, left, and right directions shown are also the up, down, left, and right directions described. The side close to the center of the nut sleeve is called the inner side, and the side far from the center of the nut sleeve is called the outer side. It should be understood that the terms "upper", "lower", "inner", "outer" and other indicating orientations or positional relationships are based on the positional relationship described in the drawings, and are only for the convenience of describing the present invention or simplifying the description, not Indicates the specific orientation that must be taken.

[0049] see Figure 1 to Figure 13 , The non-slip wrench of the present invention includes a wrench body 1, a pressing rod handle 2, a plunger 3 and a pressing component 4.

[0050] see Figure 1 to Figure 7 , The wrench body 1 is an integral piece of steel. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com