Cap grabbing head

A technology of capping and capping, which is applied in the field of grasping caps, can solve problems such as errors, affect the effect and efficiency of capping, and achieve the effects of overcoming errors, improving efficiency, and improving filling production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

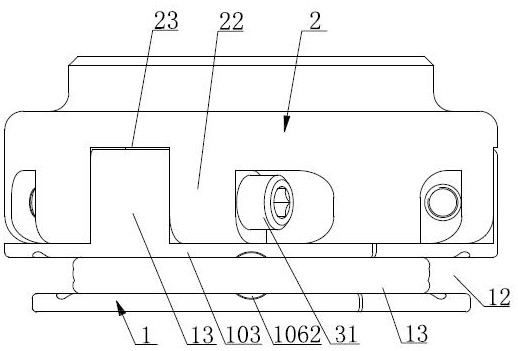

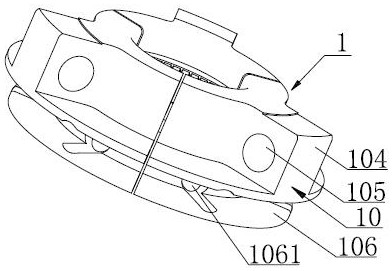

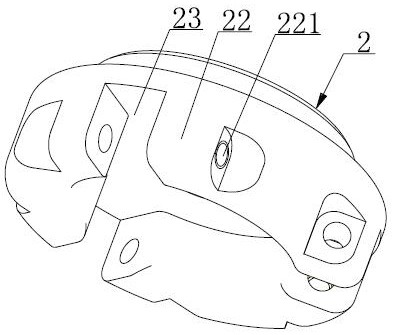

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the cap grabbing head includes: cap grabbing mold 1, the lower end of cap grabbing mold 1 is provided with a capping mechanism, and the inner wall of cap grasping mold 1 above the capping mechanism is provided with some outwardly protruding racks 11, The racks 11 are arranged at intervals around the inner wall of the cover mold 1 . The lid grip mold 1 includes at least two independent arc-shaped grip lid mold halves 10 , and the grip lid mold halves 10 are surrounded and assembled to form the grip lid mold 1 . In this embodiment, the grip lid mold 1 includes three independent arc-shaped grip lid mold halves 10 equally divided in the circumferential direction. The quantity of grab cover mold half 10 can be specifically determined according to actual conditions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com