Disc-type tool magazine and automatic tool-changing system comprehensive performance detection platform

A technology of automatic tool change and detection platform, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of lack of post-processing, neglect, lack of performance detection, etc., to avoid large equipment, reduce level requirements, The real effect of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

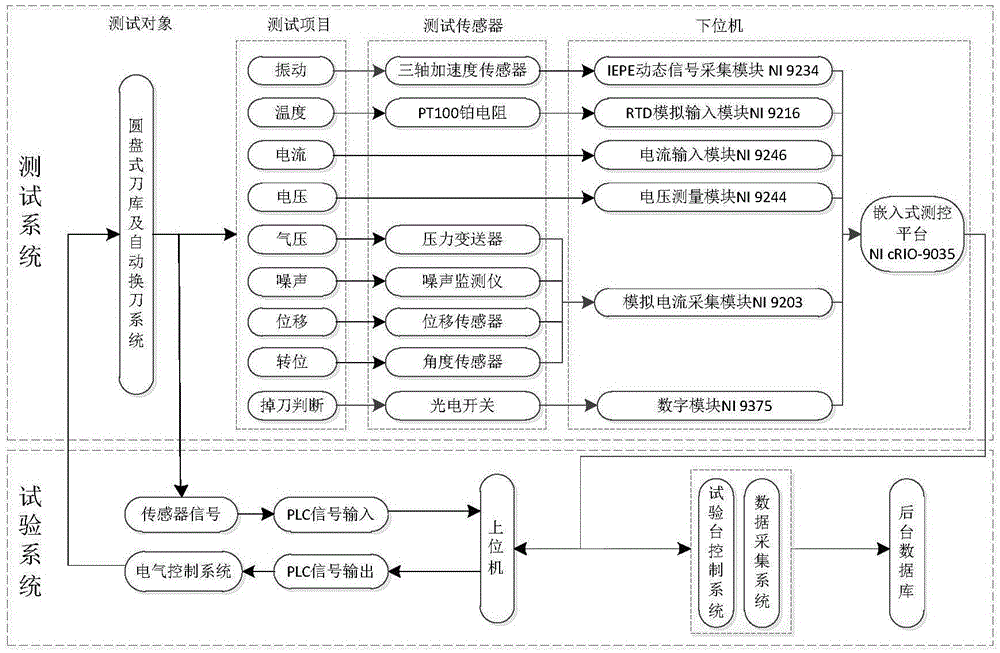

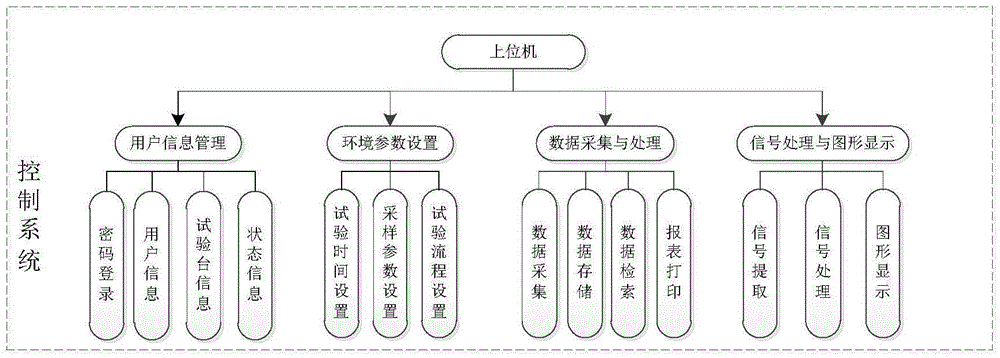

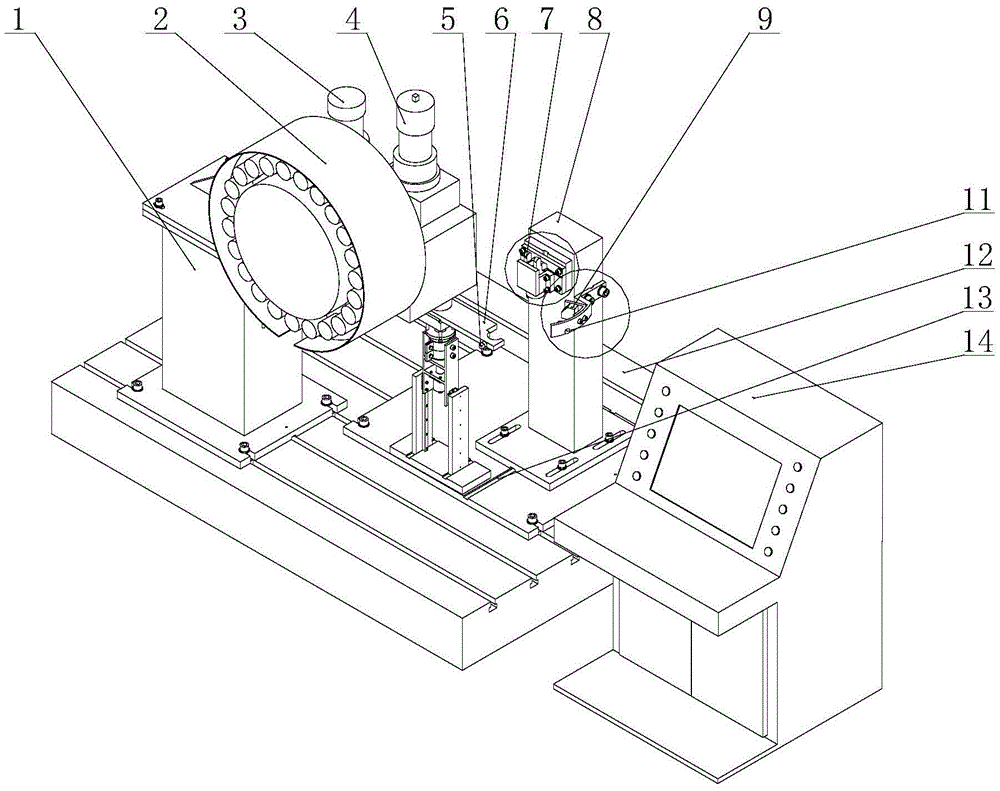

[0045] refer to figure 1 , figure 2 , a comprehensive performance testing platform for a disc tool magazine and an automatic tool changing system, the testing platform includes a test system, a test system and a control system.

[0046] The test object selected in this embodiment is the disc tool magazine BT40-24P produced by Hohhot Zhonghuan (Group) Co., Ltd.

[0047] Test items, based on the analysis of historical field test data, combined with the characteristics of the disc-type tool magazine and the structure of the automatic tool change system, the test items for comprehensive performance testing are determined to be vibration, temperature, current, voltage, air pressure, noise, displacement, rotation Position and knife drop judgment. Among them, the target of vibration detection is the cutter head and manipulator 6. Vibration is an unavoidable parameter in the operation of the mechanical system. Through the detection and analysis of vibration parameters, the comprehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com