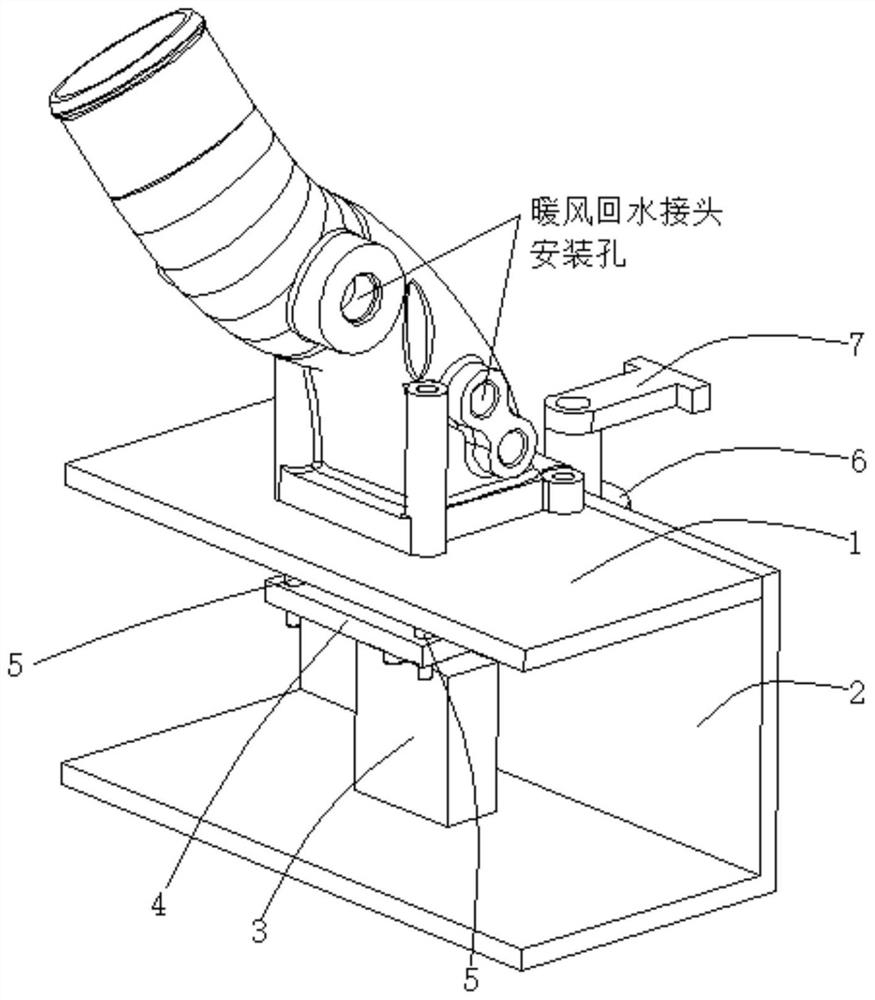

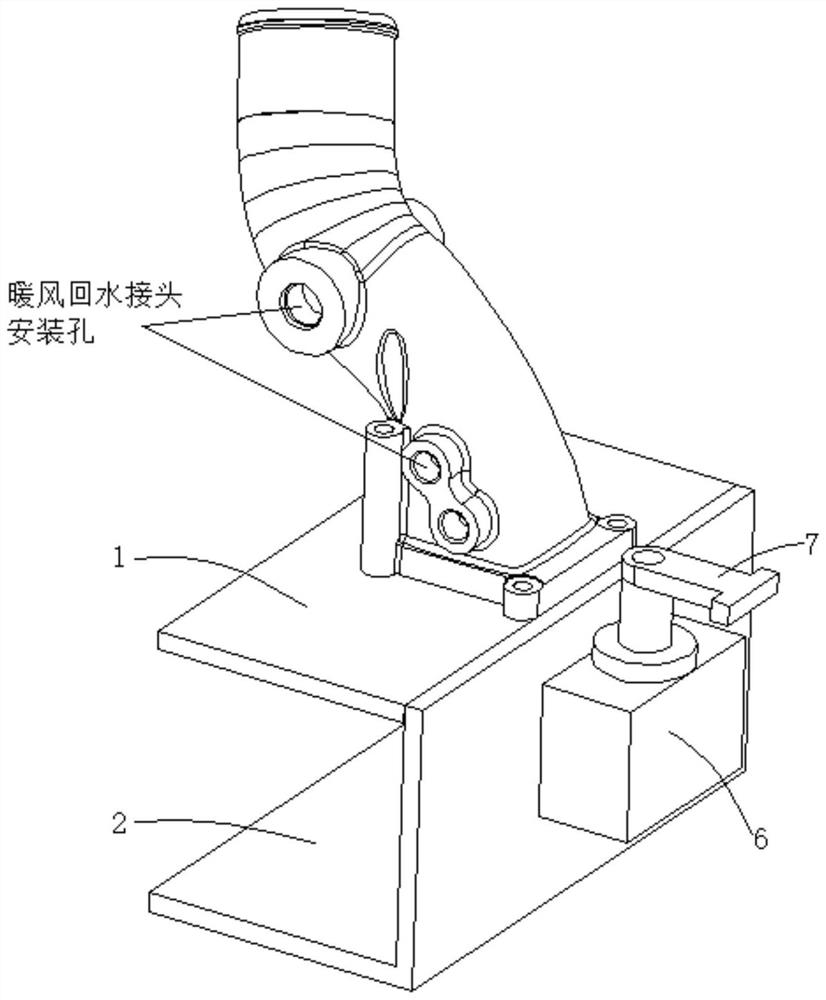

Screw-up tool for air heater backwater joint on engine water inlet pipe

A water inlet pipe and engine technology, which is applied in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of inconvenient wrench tightening, easy loosening, unstable clamping of legs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Tighten the tooling for the warm air return water connector on the water inlet pipe of the engine, first buckle the lower end of the water inlet pipe on the square platform guide seat 10 on the platform board 1, and make the lower end of the water inlet pipe contact with the platform board 1, then start the telescopic cylinder 3, The piston rod of the telescopic cylinder 3 stretches out, pushing the lifting plate 4 to move upwards along the guide rod 13, and the positioning pin 5, which is tightly connected with the lifting plate 4, moves upwards with the lifting plate 4, and the positioning pin 5 moves upward from the guide hole. 11, through the hole at the lower end of the water inlet pipe, and then start the rotary clamping cylinder 6, the piston rod of the rotary clamping cylinder 6 rotates 180 degrees first, so that the clamping head 7 clamps the piston rod of the cylinder 6 with the rotation Rotate 180 degrees above the right side of the water inlet pipe, and then ...

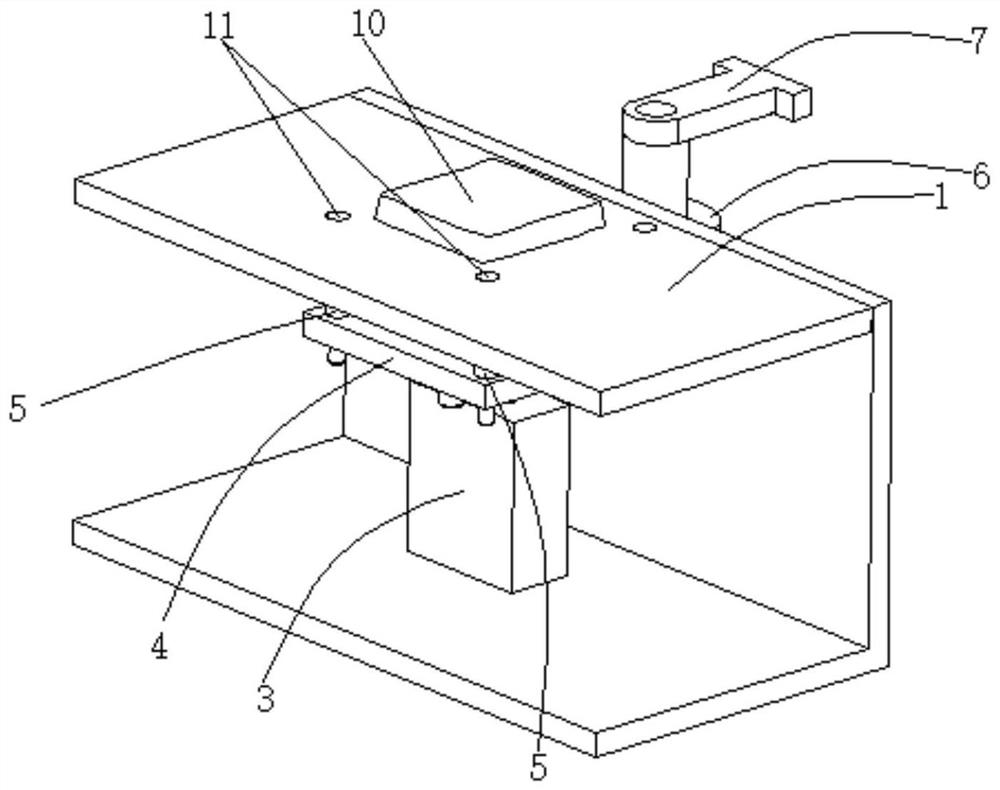

Embodiment 2

[0035] On the basis of Embodiment 1, the platform plate 1 is provided with a four-sided platform guide seat 10, which realizes the blind operation of buckling the water inlet pipe on the four-sided platform guide seat 10, and ensures that the hole at the lower end of the water inlet pipe is in contact with the platform plate. The guide hole 11 on the 1 is aligned; the platform plate 1 is provided with a guide hole 11, and the positioning pin 5 is located in the guide hole 11, which ensures that the positioning pin 5 is located in the guide hole 11 when the piston rod of the telescopic cylinder 3 is in a contracted state. In the first hole 11; the lower end of the platform plate 1 is provided with a connecting plate 12, the lower end of the connecting plate 12 is fastened with a guide rod 13, and the lifting plate 4 is provided with a guide hole 2 14, and the guide rod 13 is connected with the guide hole Two 14 sliding connections ensure the horizontality of the lifting plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com