Pipe joint assembly and transportation equipment

A technology of special equipment and components, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipes, etc., can solve the problems of increased construction difficulty, decreased installation stability, and increased difficulty, so as to simplify the installation process and improve reliability. performance, a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

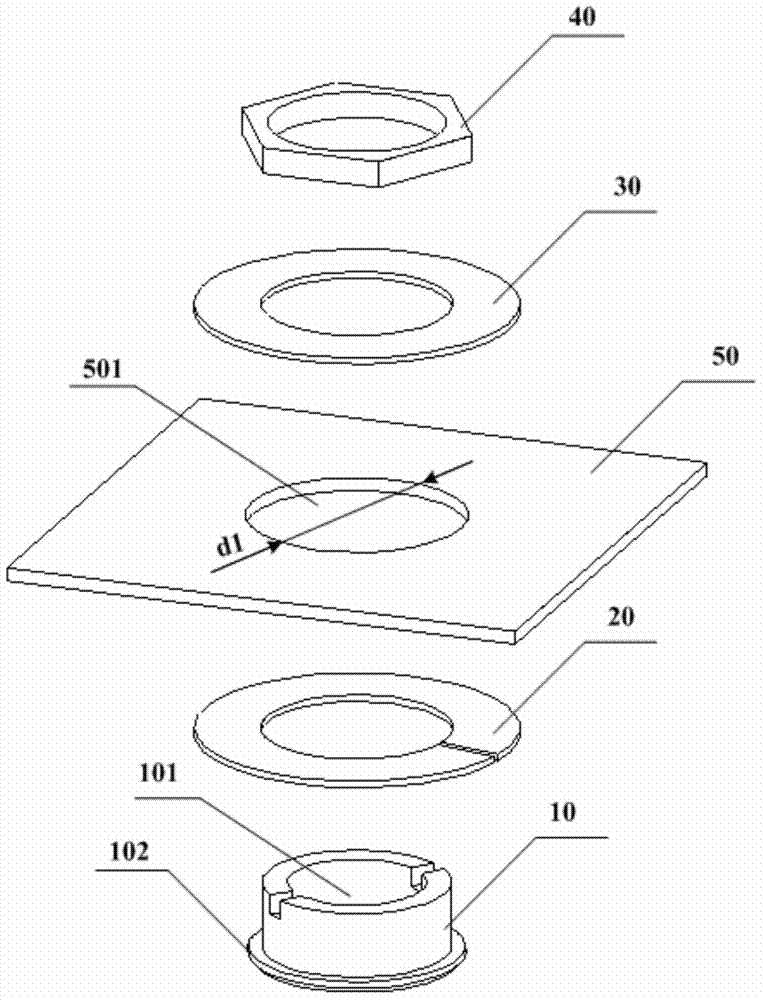

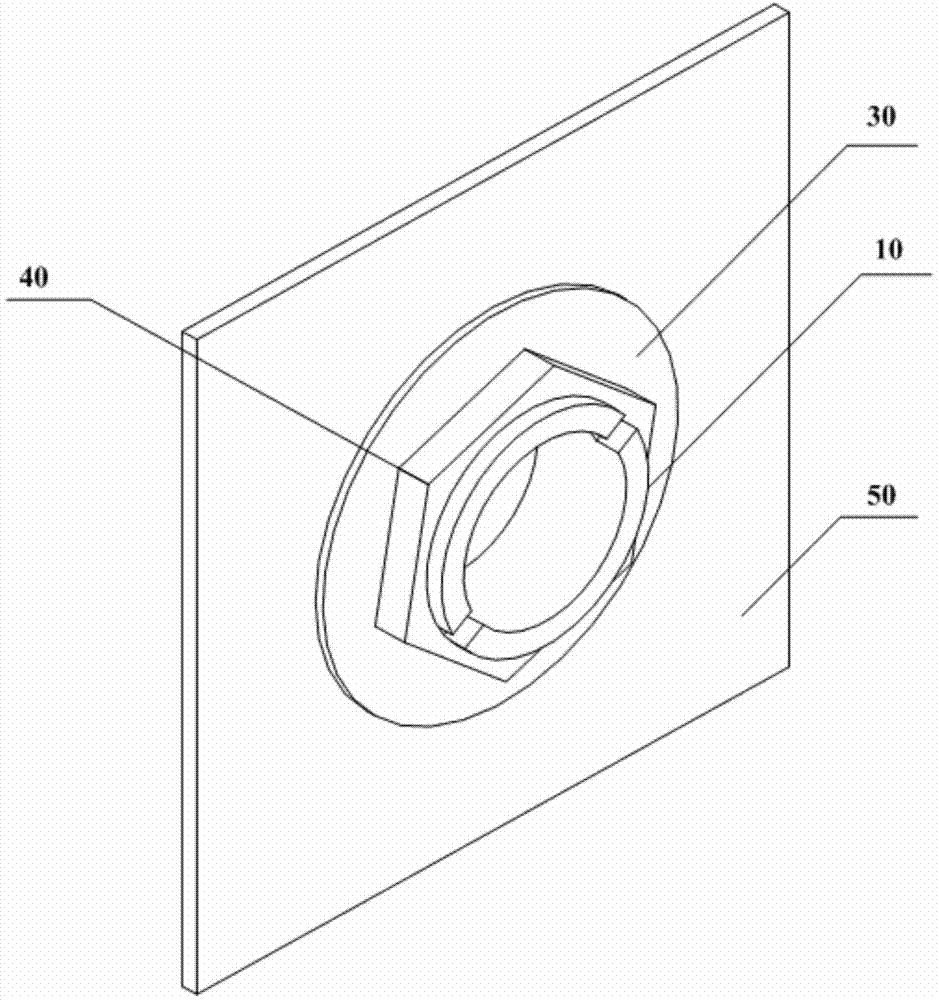

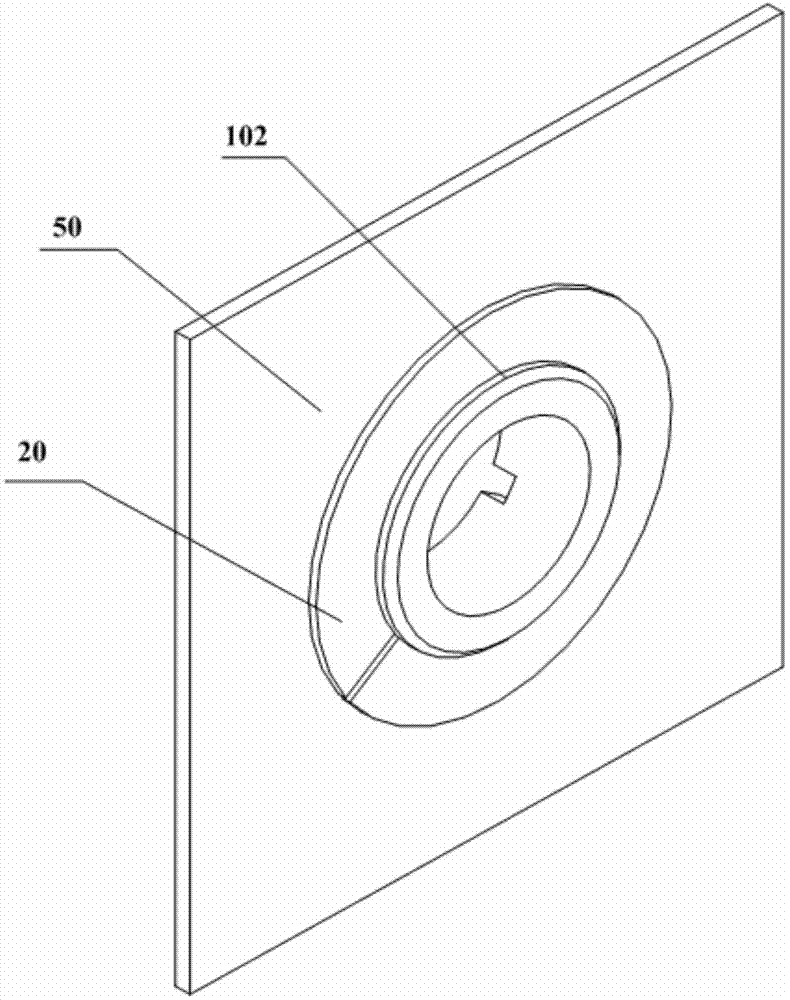

[0035] The purpose of the present invention is to provide a pipe joint assembly and a transportation equipment, which can simplify the installation process of special equipment on the pipeline, make the application scope of the pipe joint assembly wider, and improve the reliability of installation. When the pipe joint assembly provided by the embodiment of the present invention is applied to transportation equipment, since the outer side of the pipe joint has a stepped surface, one end of the pipe joint is penetrated through the opening of the pipe wall, and the inner pressure piece is located between the stepped surface and the inner wall of the pipe wall. During the time, the outer pressure piece is located on the outside of the pipe wall. By tightening the fasteners, the inner pressure piece and the outer pressure piece located on both sides of the pipe wall clamp the pipe wall, so that the pipe joint assembly is reliably fixed on the pipe wall. Special equipment is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com