Tooth-shaped gasket for preventing following rotation of bolt and high-strength bolt connecting pair

A technology of tooth shape and gasket, applied in the direction of bolts, connecting members, screws, etc., can solve the problems of harsh use environment, difficult operation, assembly failure, etc., to ensure equipment operation and safe production, reduce use and maintenance costs, guarantee The effect of assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

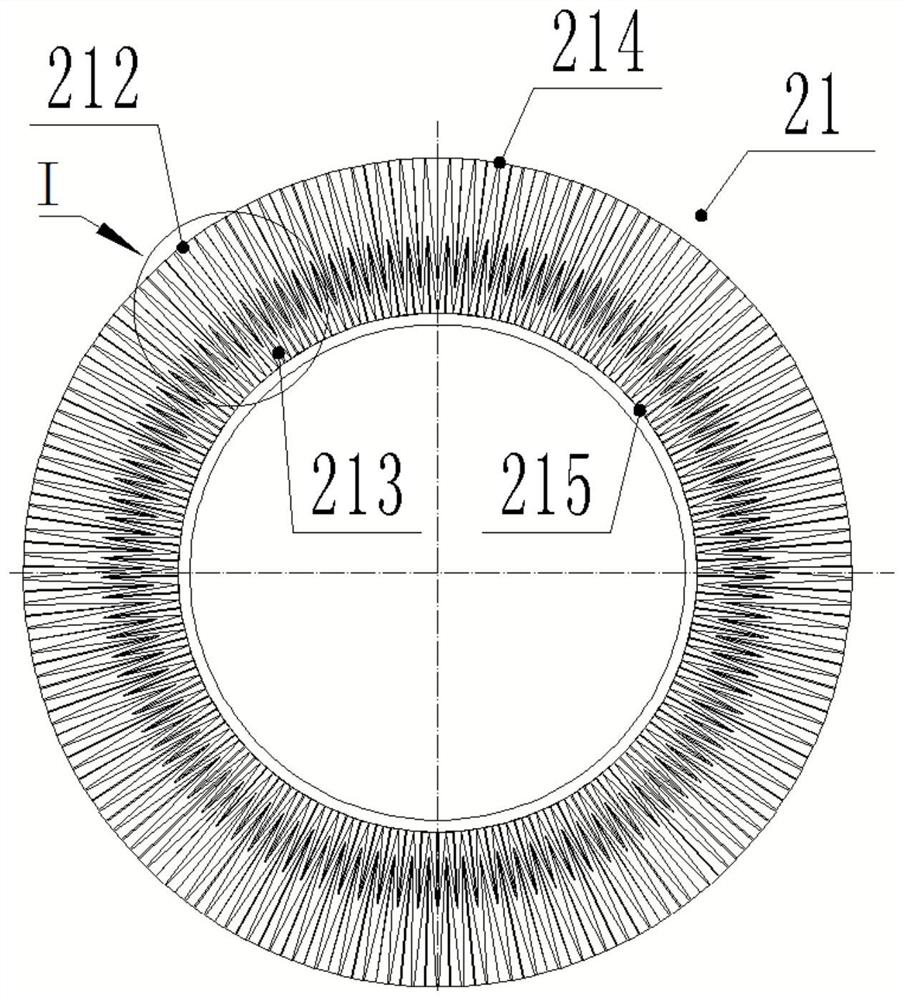

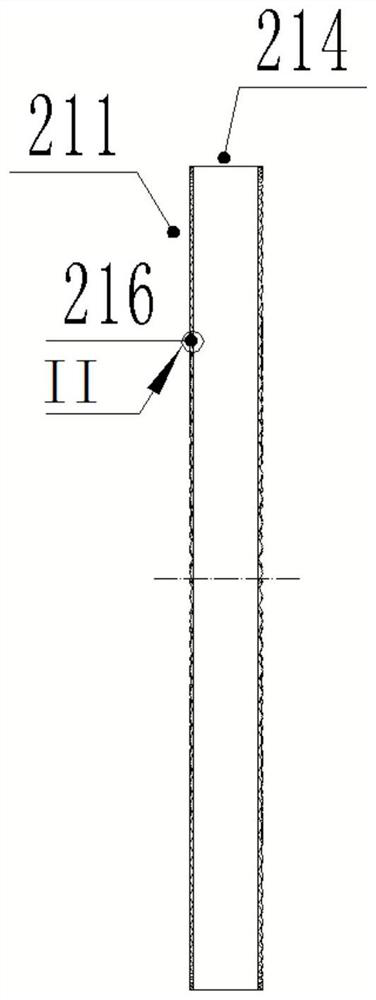

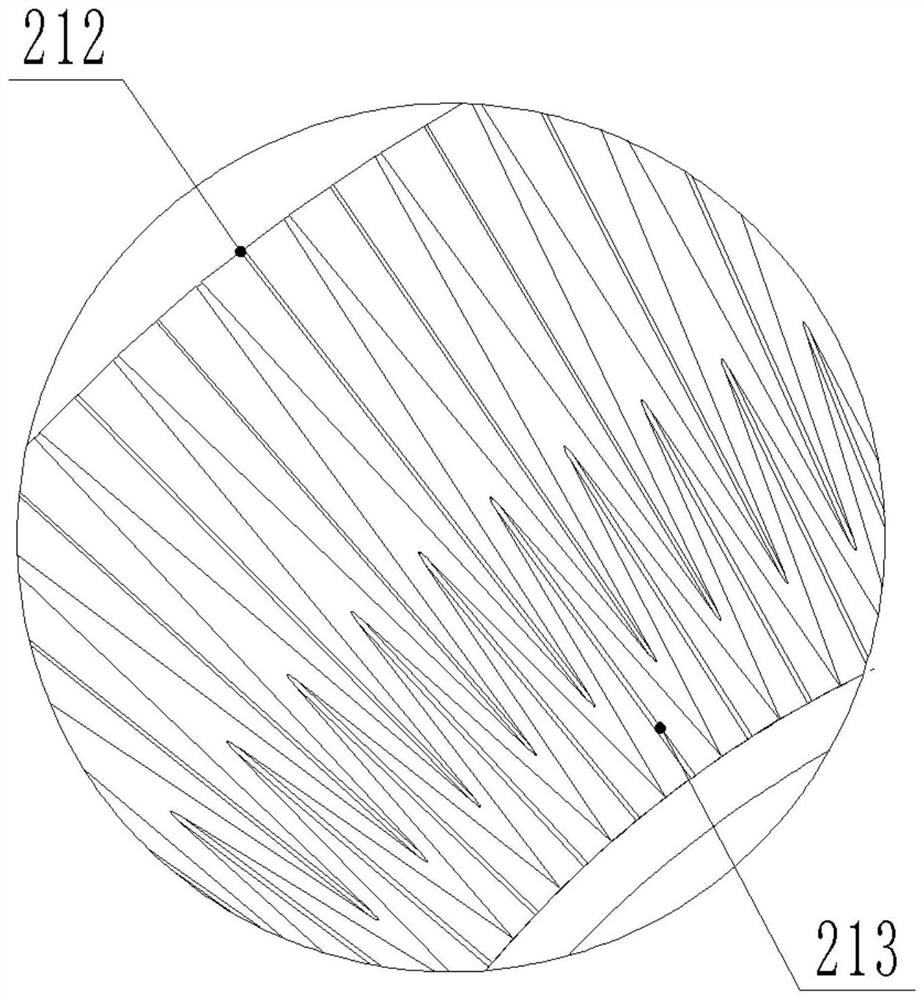

[0031] Such as Figure 1-5 As shown, an anti-bolt heel-toothed gasket 2 includes a gasket body 21, and two end faces 211 of the gasket body are respectively provided with radial tooth shapes along the radial direction; the radial tooth shapes include A plurality of external tooth shapes 212 extending from the position of the outer circular surface 214 of the gasket along the end surface to the inside, and a plurality of internal tooth shapes 213 extending from the position of the inner hole 215 of the gasket along the end surface to the outside. The tooth shapes are alternately arranged at intervals, the interval between two adjacent outer tooth shapes and inner tooth shapes is relatively small, and the outer tooth shapes and inner tooth shapes are arranged densely and in large numbers.

[0032] The outer tooth shape 212 gradually narrows inward from the position of the outer circular surface, and gradually becomes lower in height, and the inner tooth shape 213 gradually narro...

Embodiment 2

[0038] The external tooth shape and the internal tooth shape of the present invention are obtained through a cold stamping process.

Embodiment 3

[0040] Such as Figure 5 As shown, a high-strength bolt connection pair includes a first connected part 3, a second connected part 4, a bolt 1, and a nut 6. The first connected part 3 and the second connected part 4 are connected through the bolt 1 and the nut 6, Between the head of the bolt 1 and the connected part 3, an anti-bolt heel-tooth-shaped washer 2 is provided.

[0041] A nut washer 5 is arranged between the connected part 2 and the nut.

[0042] The nut washer 5 is a flat washer.

[0043] Structure and working principle of the present invention illustrate:

[0044]The present invention is based on the common flat pad, wherein the outer tooth shape and the inner tooth shape are obtained by cold stamping process, and radial tooth shapes interlaced inside and outside are formed on both ends. Due to the difference in diameter between the outer circular surface and the inner hole of the gasket, and the number of teeth of the outer tooth shape and the inner tooth shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com