A low-noise water supply pump assembly method

An assembly method and water supply pump technology, which are applied in the field of mechanical assembly, can solve problems such as low coaxiality, low friction noise of shafting, and excessive noise, so as to reduce the difficulty of assembly and debugging, make assembly reasonable and feasible, and prevent resonance. The effect of amplifying noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

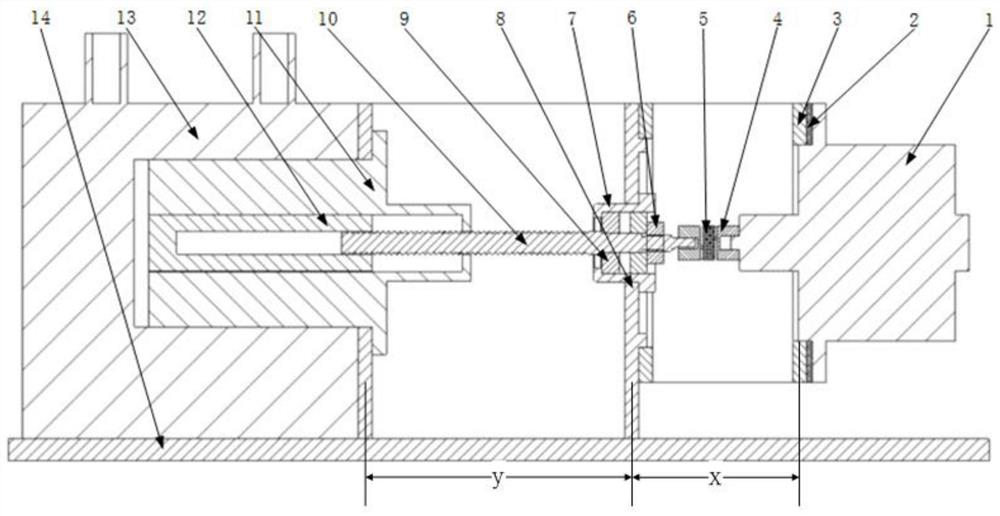

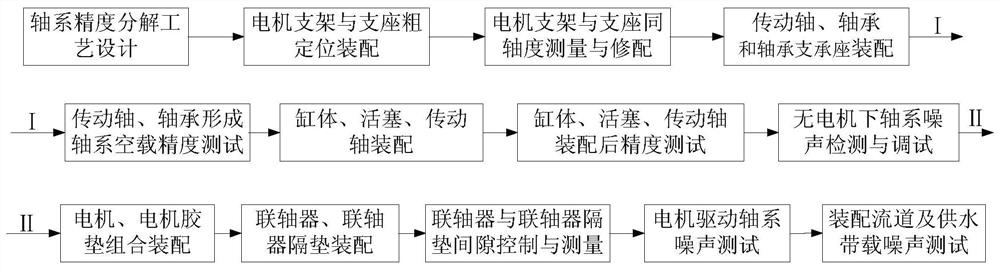

[0032] By describing the present invention in detail below, the features and advantages of the present invention will become more apparent with these descriptions.

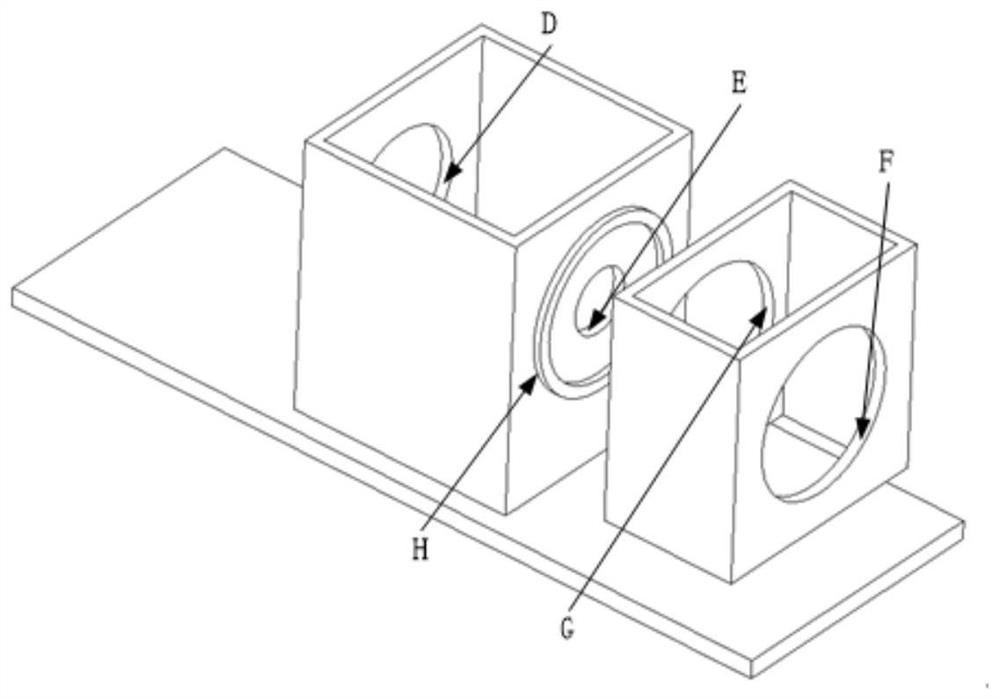

[0036] The coaxiality measurement of the motor bracket and the bearing hole position: using high-precision three-coordinates or detection equipment such as a laser tracker

[0049] The content that is not described in detail in the specification of the present invention belongs to the well-known technology of those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com