A Standard Trajectory Test and Analysis System for CNC Machine Tool

A standard trajectory, test and analysis technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of high installation conditions and insufficient depth of CNC machine tools, and achieve simple methods, low costs, and easy setup and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

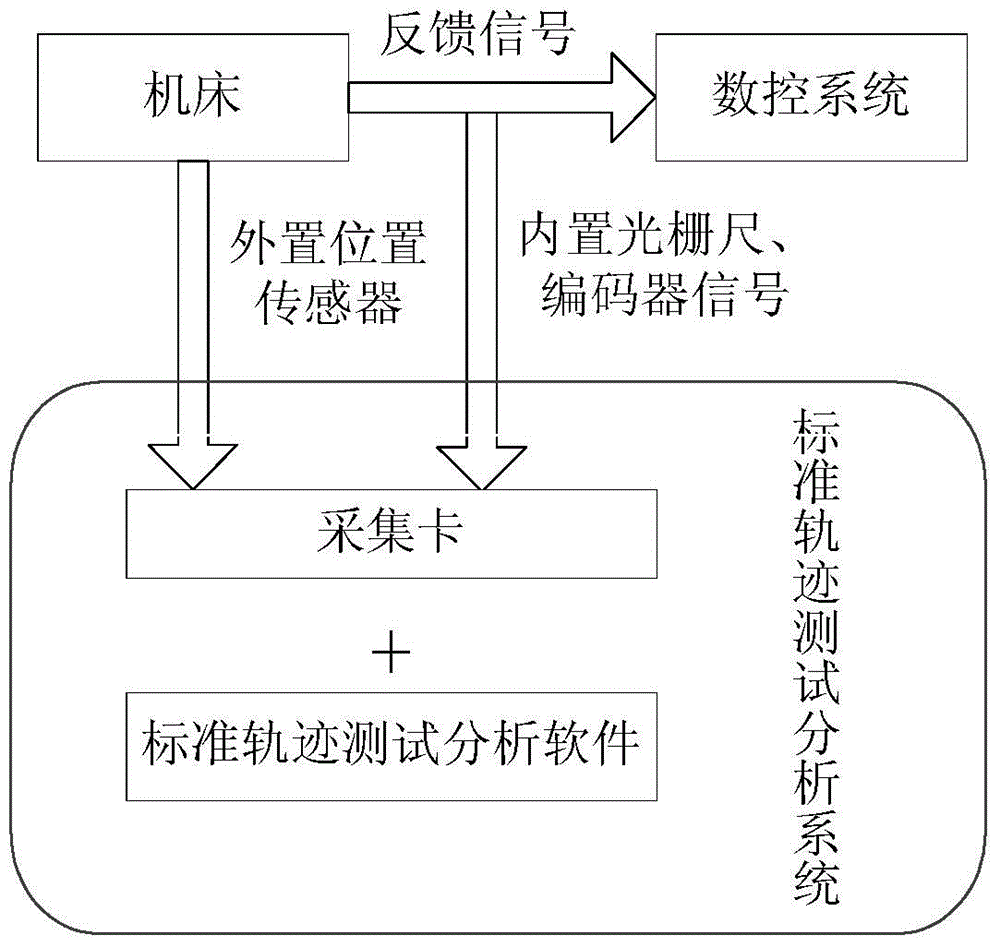

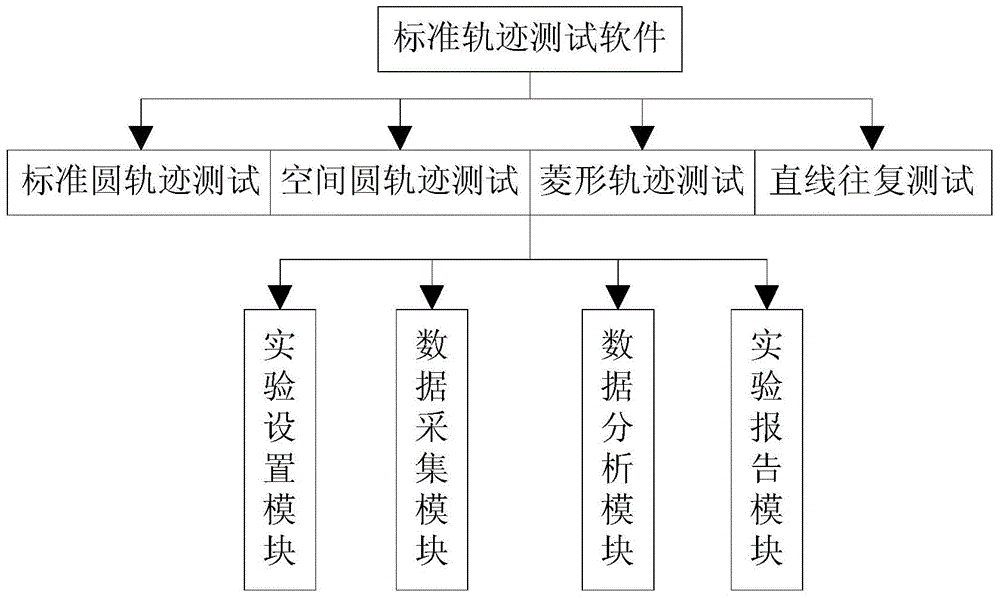

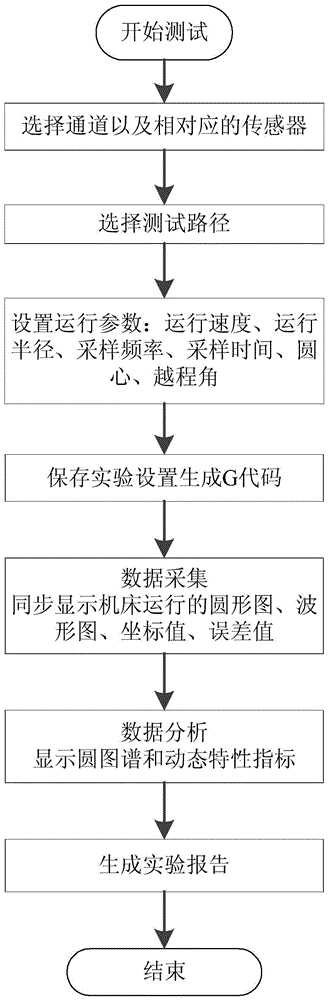

[0018] A standard trajectory test and analysis system for CNC machine tools, consisting of hardware and software, refer to figure 1 , the hardware part collects the built-in encoder, grating ruler signal and external position sensor signal of the CNC machine tool, which can realize synchronous acquisition of multi-channel signals, and use the data acquisition card to realize the built-in encoder, grating ruler signal and external position sensor signal of the CNC machine tool Carry out synchronous or asynchronous acquisition, and use the software of standard trajectory test analysis to realize the analysis and processing of information.

[0019] The synchronous acquisition of multi-channel signals refers to the synchronous acquisition of multi-signal formats that can realize 1vpp signals, TTL signals, and Endat signals. The highest sampling frequency of synchronous acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com