A positioning and grasping method for electronic liquid crystal screens of different sizes

A liquid crystal screen and electronic technology, applied in the field of automation, can solve the problems of time-consuming operation, high personnel cost, and difficult operation, etc., and achieve the effect of improving labor efficiency and ensuring assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

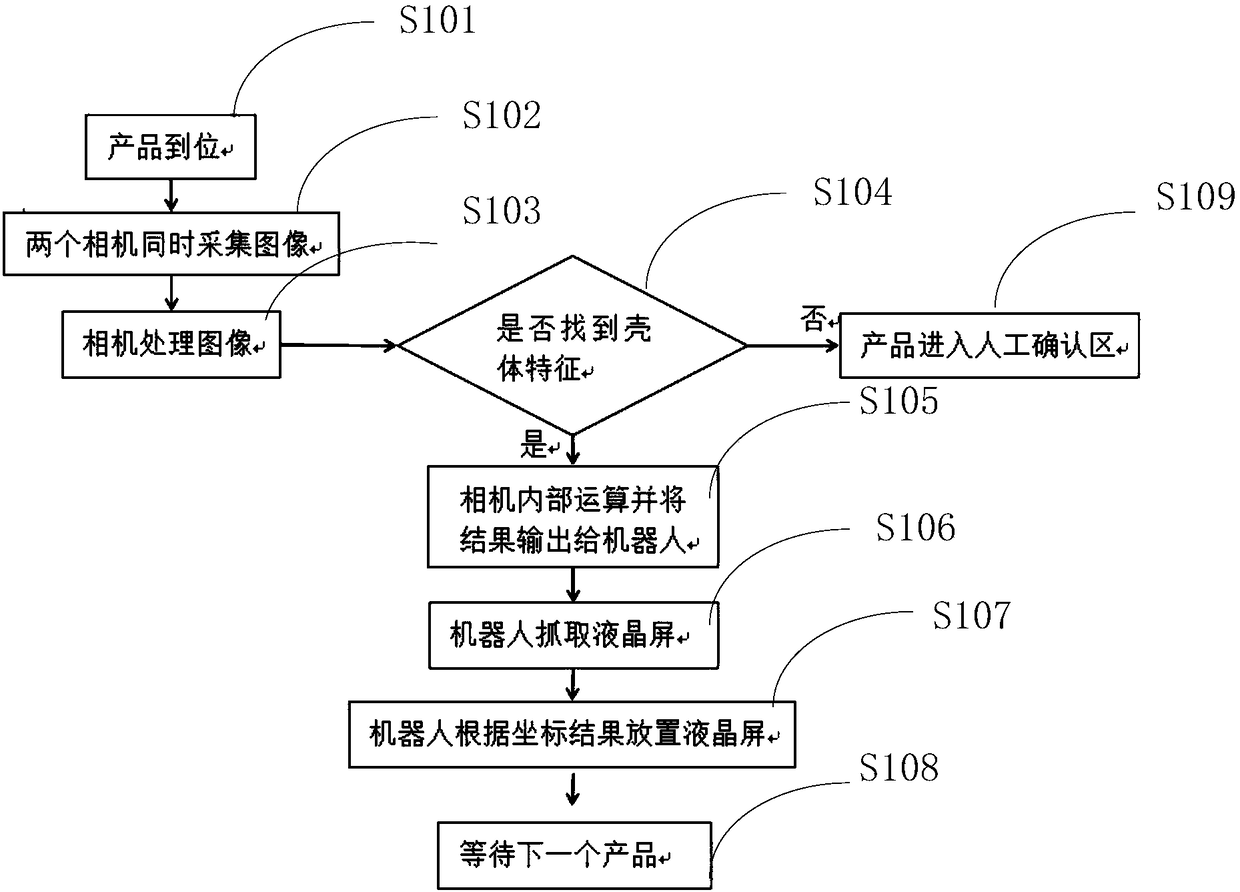

[0022] Such as figure 1 As shown, a positioning and capturing method for electronic LCD screens of different sizes includes the following steps: S101, the product is in place; S102, two cameras collect images at the same time; S103, the camera processes the image; S104, whether the shell feature is found; S105, If finding the shell feature, the camera internally calculates and outputs the calculation result to the robot; S106, the robot grabs the LCD screen; S107, the robot places the LCD screen according to the calculation result. S108, waiting for the next product; S109, if the shell feature is not found, the product enters the manual confirmation area.

[0023] The image processing steps are specifically: using two image acquisition cameras to collect two top-angle images of the electronic liquid crystal screen, and analyze the images, use image matching for the two top graphics, and according to the successfully matched images, the two cameras The size and the internal calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com