Automatic deslagging conveying belt of earth pressure balance shield machine

A technology of automatic slag removal and earth pressure balance, which is applied to conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of high maintenance and use cost of conveyor belts, large surface wear of smooth belts, and difficult transportation of smooth belts. , to achieve the effect of quick and smooth removal of slag, reduce wear and improve slag carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0042] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

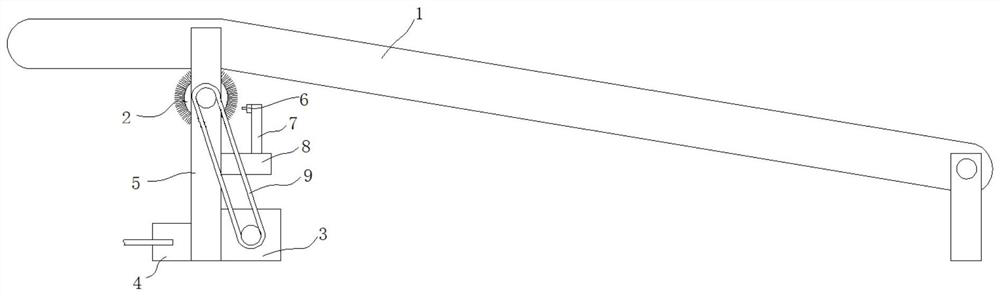

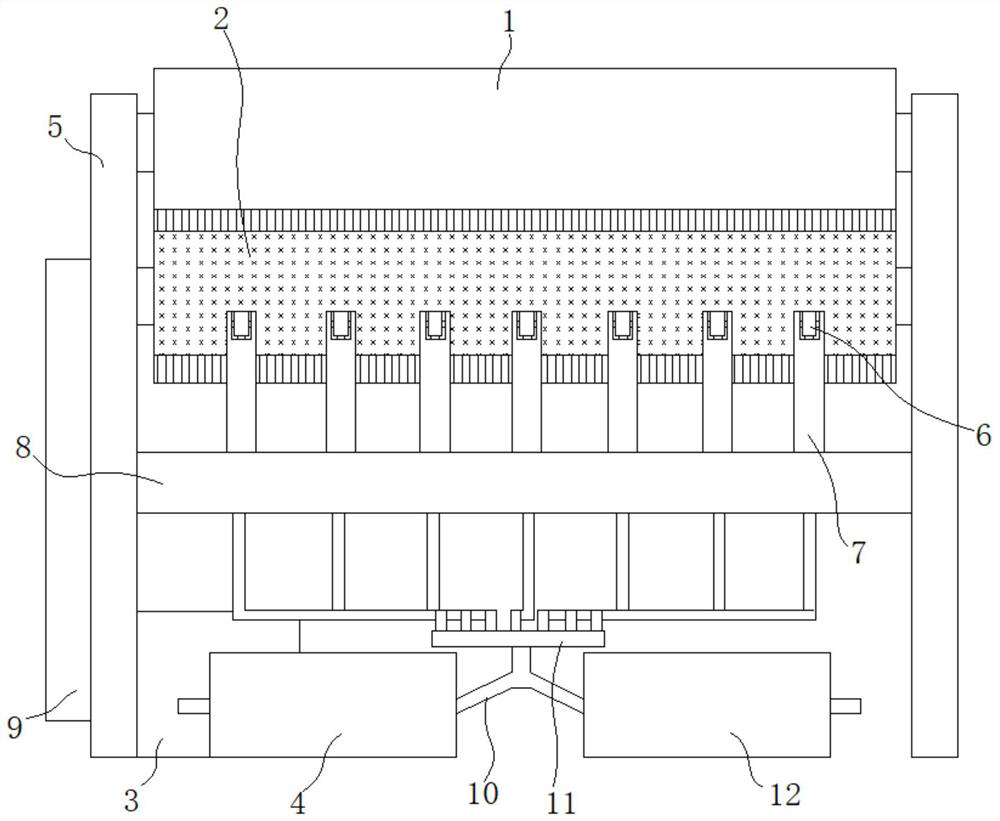

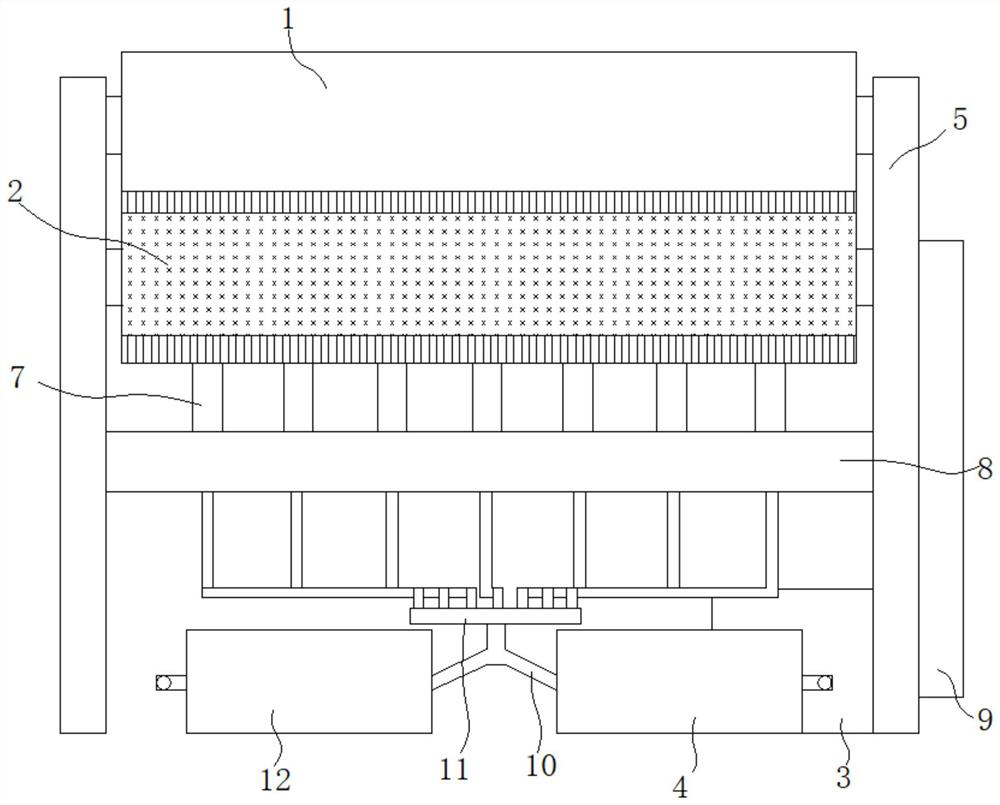

[0043] Such as figure 1 and Figure 5 As shown, an automatic slag removal conveyor belt 1 for an earth pressure balance shield machine, including a conveyor belt 1;

[0044] The belt outer surface of the conveyor belt 1 is provided with a plurality of herringbone protrusions 13 along its extending direction;

[0045] A brush roller is arranged across the bottom of the rear part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com