Seabed shield slurry viscosity reducer as well as use method and application thereof

A viscosity reducer and mud technology, which is applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of high construction cost, blockage of mud cake and mud circulation pipeline, loss of mud separation equipment, etc., to improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

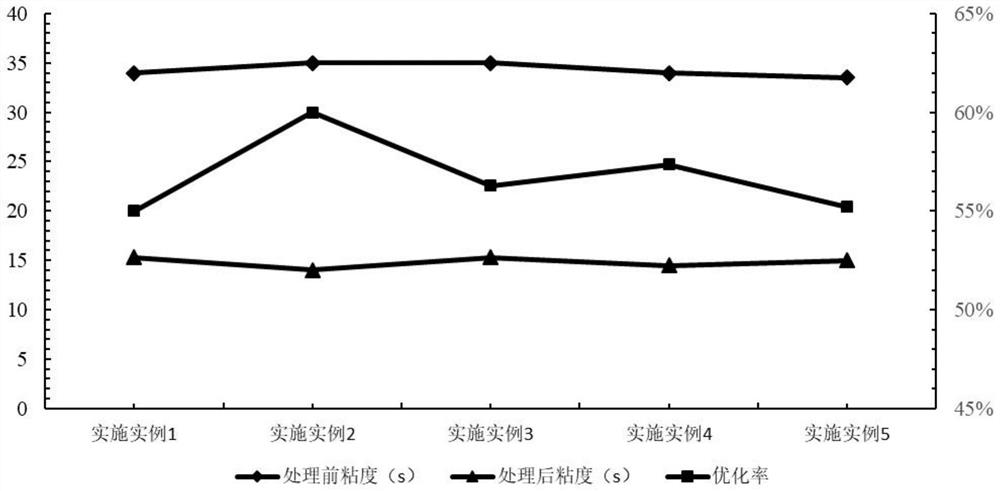

[0040] Embodiment 1 of the present invention provides a kind of shield mud viscosity reducer, and it comprises the component of following parts by weight: 1 part of 300ml shield mud (Su type funnel viscometer measures viscosity), 0.008 part of aluminum sulfate, lignin sulfonate 0.0056 parts of acid salt, 0.0016 parts of sodium polyphosphate, 0.01 part of industrial defoamer, and 0.0008 parts of industrial grade sodium carbonate.

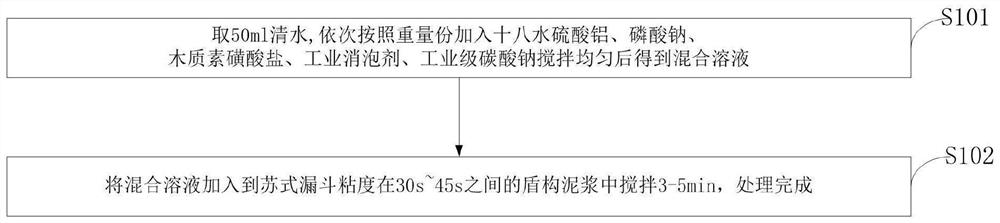

[0041] Take 50ml of clear water, add Al in turn according to weight 2 (SO 4 ) 3 18H 2 O, Na 5 P 3 o 10 , lignin sulfonate, industrial defoamer, and industrial-grade sodium carbonate are stirred evenly to obtain a mixed solution, and the mixed solution is added to the shield mud with a Soviet funnel viscosity between 30s and 45s and stirred for 3-5min, and the treatment is completed .

Embodiment 2

[0043] Embodiment 2 of the present invention provides a kind of shield mud viscosity reducer, and it comprises the component of following parts by weight: 1 part of 300ml shield mud (Su type funnel viscometer measures viscosity), 0.008 part of aluminum sulfate, lignin sulfonate Salt 0.0064 parts, sodium polyphosphate 0.0008 parts, industrial defoamer 0.02 parts, industrial grade sodium carbonate 0.0008 parts.

[0044] The using method of the shield mud viscosity reducer is the same as that of the shield mud viscosity reducer in Example 1.

Embodiment 3

[0046] Embodiment 3 of the present invention provides a kind of shield mud viscosity reducer, and it comprises the component of following parts by weight: 1 part of 300ml shield mud (Su type funnel viscometer measures viscosity), 0.0096 part of aluminum sulfate, lignin sulfonate Salt 0.0064 parts, sodium polyphosphate 0.0016 parts, industrial defoamer 0.005 parts, industrial grade sodium carbonate 0.0008 parts.

[0047] The using method of the shield mud viscosity reducer is the same as that of the shield mud viscosity reducer in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com