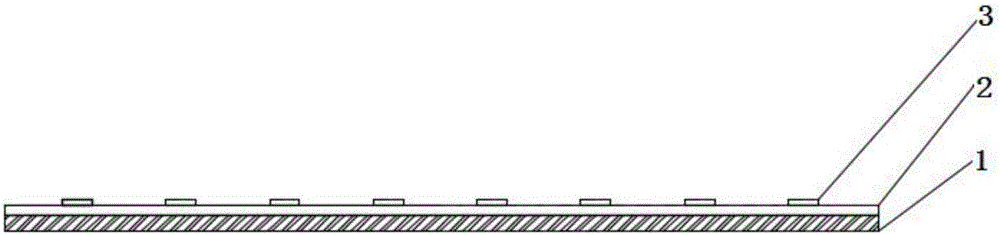

LED patch light source

A technology of LED patch and light source, which is applied in the field of LED lighting, can solve the problems of high thermal conductivity, poor plasticity, and easy to break, and achieve high thermal conductivity, reduced packaging area, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Ceramic slurry includes the following components:

[0058] 80 parts by weight of alumina ceramic powder,

[0059] The bisphenol A type epoxy resin of 15 parts by weight,

[0060]1 part by weight of acetone,

[0061] The polyether defoamer of 1 weight part,

[0062] The KH570 coupling agent of 1 weight part,

[0063] 2 parts by weight of aniline curing agent.

[0064] S1: Ceramic powder preparation:

[0065] S11: select the particle size D50 value of 20um alumina ceramic powder, add water solvent, and ball mill the slurry obtained for 5 hours,

[0066] S12: Filter the slurry to remove water and freeze-dry for 24 hours to obtain a ceramic powder with a D50 value of 5um and a water content of less than 1%.

[0067] S2: Preparation of ceramic slurry: Weigh 80 parts by weight of alumina ceramic powder, 15 parts by weight of bisphenol A epoxy resin, 1 part by weight of acetone, 1 part by weight of polyether defoamer, 1 part by weight The KH570 coupling agent and the an...

Embodiment 2

[0084] Ceramic slurry includes the following components:

[0085] 70 parts by weight of alumina ceramic powder,

[0086] 10 parts by weight of bisphenol A type epoxy resin,

[0087] 0.8 parts by weight of ethyl acetate,

[0088] 0.8 parts by weight of silicone defoamer,

[0089] The KH560 coupling agent of 0.8 weight part,

[0090] 1.5 parts by weight of an acid anhydride curing agent.

[0091] S1: Ceramic powder preparation:

[0092] S11: select the particle size D50 value of 20um alumina ceramic powder, add water solvent, and ball mill the slurry obtained for 5 hours,

[0093] S12: Filter the slurry to remove water and freeze-dry for 24 hours to obtain a ceramic powder with a D50 value of 5um and a water content of less than 1%.

[0094] S2: Preparation of ceramic slurry: Weigh 70 parts by weight of alumina ceramic powder, 10 parts by weight of bisphenol A epoxy resin, 0.8 parts by weight of ethyl acetate, 0.8 parts by weight of organosilicon defoamer, 0.8 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com