CEM-3 type copper-clad laminated plate base paper manufacturing method

A manufacturing method and technology of laminated boards, which are applied in chemical instruments and methods, lamination, and layered products, etc., can solve the problem of poor tracking resistance, peeling resistance, cracking resistance, etc. of copper-clad laminated board base paper. Poor impact performance, shortened shelf life of adhesive sheets, etc., to achieve the effects of improving peel strength, enhancing adhesiveness and flame retardancy, and reducing curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

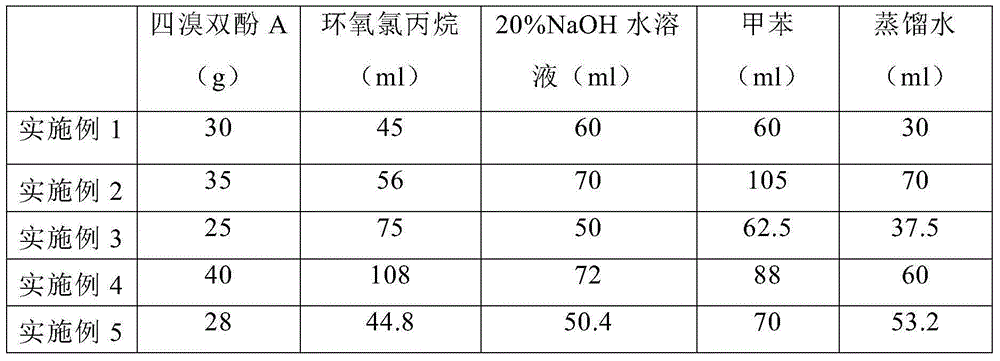

Embodiment 1

[0066] Add tetrabromobisphenol A and epichlorohydrin into the reaction kettle, stir at room temperature for 25 minutes, heat up to 60°C, add 20% NaOH aqueous solution dropwise, finish the dropwise addition within 30 minutes, and raise the temperature to 70°C after the dropwise addition ℃, reacted for 2h, added distilled water and toluene, stirred until dissolved, separated, and vacuum distilled to obtain the brominated bisphenol A type epoxy resin;

Embodiment 2

[0068] Add tetrabromobisphenol A and epichlorohydrin into the reaction kettle, stir at room temperature for 30 minutes, heat up to 50°C, add 20% NaOH aqueous solution dropwise, finish the dropwise addition within 60 minutes, and raise the temperature to 80°C after the dropwise addition ℃, reacted for 1.5h, added distilled water and toluene, stirred until dissolved, separated, and vacuum distilled to obtain the brominated bisphenol A epoxy resin;

Embodiment 3

[0070] Add tetrabromobisphenol A and epichlorohydrin into the reaction kettle, stir at room temperature for 28 minutes, heat up to 60°C, add 20% NaOH aqueous solution dropwise, and finish the dropwise addition within 50 minutes, then raise the temperature to 75°C ℃, reacted for 2h, added distilled water and toluene, stirred until dissolved, separated, and vacuum distilled to obtain the brominated bisphenol A type epoxy resin;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com