Insulated and flame-retardant cable

A technology for flame-retardant cables and insulating layers, which is applied in the direction of insulated cables, insulators, and insulated conductors. Equipment requirements, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

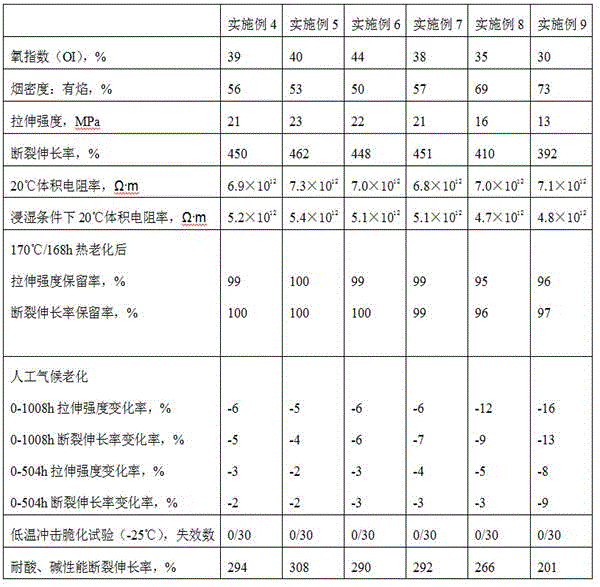

Examples

Embodiment 1

[0023] (1) Add 20ml of anhydrous dichloromethane into the three-necked flask, and add 1.34g (0.01mol) of trihydroxypropane to dissolve it all, and take the monomer 3-methyl-3-hydroxymethyloxetane Alkanes 9.18g (0.09mol) and dissolved in 50ml of anhydrous dichloromethane, poured into the constant pressure dropping funnel (the molar ratio of nuclear molecules and monomers is 1:9), equipped with a thermometer, under N 2 Under protected conditions, add 6.24g (0.044mol) BF with a syringe 3 ·OEt 2 , keeping the temperature constant at 30°C, adjusting the constant pressure dropping funnel to control the dropping speed, the dropping time is 4 hours, and the heat preservation reaction is 48 hours to obtain the hyperbranched polymer;

[0024] (2) Succinic anhydride modified hyperbranched polymer

[0025] Weigh 12.01g (0.12mol) of succinic anhydride and dissolve it in 50ml of anhydrous dichloromethane, add it to the hyperbranched polymer synthesized in step (1), then repeatedly vacuumi...

Embodiment 2

[0030] (1) Add 20ml of anhydrous dichloromethane into the three-necked flask, and add 0.67g (0.005mol) of trihydroxypropane to dissolve it all, and take the monomer 3-methyl-3-hydroxymethyloxetane Alkanes 10.71g (0.105mol) and dissolved in 50ml of anhydrous dichloromethane, poured into the constant pressure dropping funnel (the molar ratio of nuclear molecules and monomers is 1:21), equipped with a thermometer, in N 2 Under protected conditions, add 7.28g (0.051mol) BF with a syringe 3 ·OEt 2 , keep the temperature constant at 30°C, adjust the constant pressure dropping funnel to control the dropping speed, after the dropping time is 4 hours, keep the temperature for 48 hours, and obtain the hyperbranched polymer;

[0031] (2) Weigh 24.016g (0.24mol) of succinic anhydride and dissolve it in 50ml of anhydrous dichloromethane, add it to the hyperbranched polymer synthesized in step (1), then repeatedly vacuumize and blow nitrogen to remove Air in the reaction device, control t...

Embodiment 3

[0036] (1) Add 20ml of anhydrous dichloromethane into the three-necked flask, and add 0.268g (0.002mol) of trihydroxypropane to dissolve it all, and take the monomer 3-methyl-3-hydroxymethyloxetane Dissolve 9.18g (0.09mol) of alkane in 50ml of anhydrous dichloromethane, pour it into a constant pressure dropping funnel (the molar ratio of nuclear molecules to monomers is 1:45), install a thermometer, and 2 Under protected conditions, add 6.24g (0.044mol) BF with a syringe 3 ·OEt 2 , keep the temperature constant at 30°C, adjust the constant pressure dropping funnel to control the dropping speed, after the dropping time is 4 hours, keep the temperature for 48 hours, and obtain the hyperbranched polymer;

[0037] (2) Weigh 48.032g (0.48mol) of succinic anhydride and dissolve it in 100ml of anhydrous dichloromethane, add it to the hyperbranched polymer synthesized in step (1), then repeatedly vacuumize and blow nitrogen to remove Air in the reaction device, control the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com