Water-based adhesive, preparation method, adhesive tape and preparation method thereof

A water-based adhesive and tape technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of poor bonding performance, low toxicity, environmental protection, complicated operation, etc., and achieve electrical insulation performance Stable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

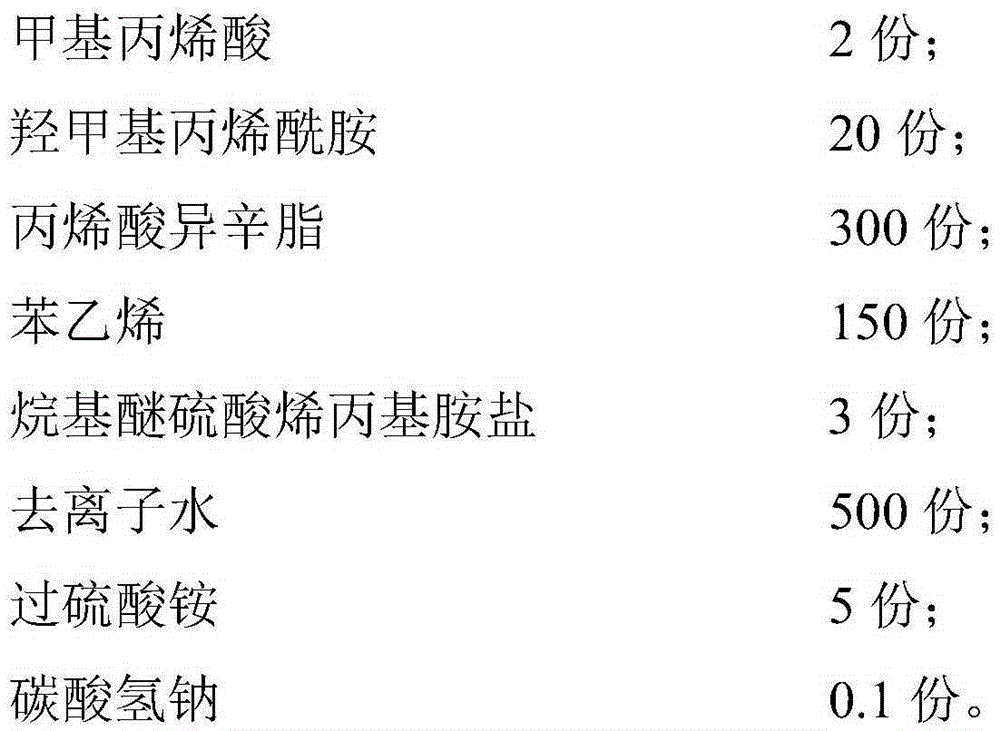

[0025] The preparation method of water-based adhesive of the present invention comprises:

[0026] S1: Preparation of pre-emulsion: Add 2.5-9.5 parts of reactive emulsifier and 0.08-0.9 parts of sodium bicarbonate to the pre-emulsification tank, mix with 100-250 parts of deionized water and stir evenly, and add 2- 30 parts of methacrylic acid or acrylic acid, 1-20 parts of methylol acrylamide, 0-300 parts of isooctyl acrylate, 0-200 parts of vinyl nonanoate, and 0-300 parts of styrene are stirred evenly to obtain the pre- Emulsion;

[0027] S2: Add 150-350 parts of deionized water, the remaining reactive emulsifier and sodium bicarbonate to the reactor; heat up to 75-85°C, take 1-5% of the pre-emulsion prepared in step S1 Add, and add the diluent prepared by adding 0.3-6 parts of ammonium persulfate and 20-50 parts of deionized water;

[0028] S3: Insulate for 10 minutes, start to drop the remaining pre-emulsion prepared in step S1 and the remaining ammonium persulfate and 2...

Embodiment 1

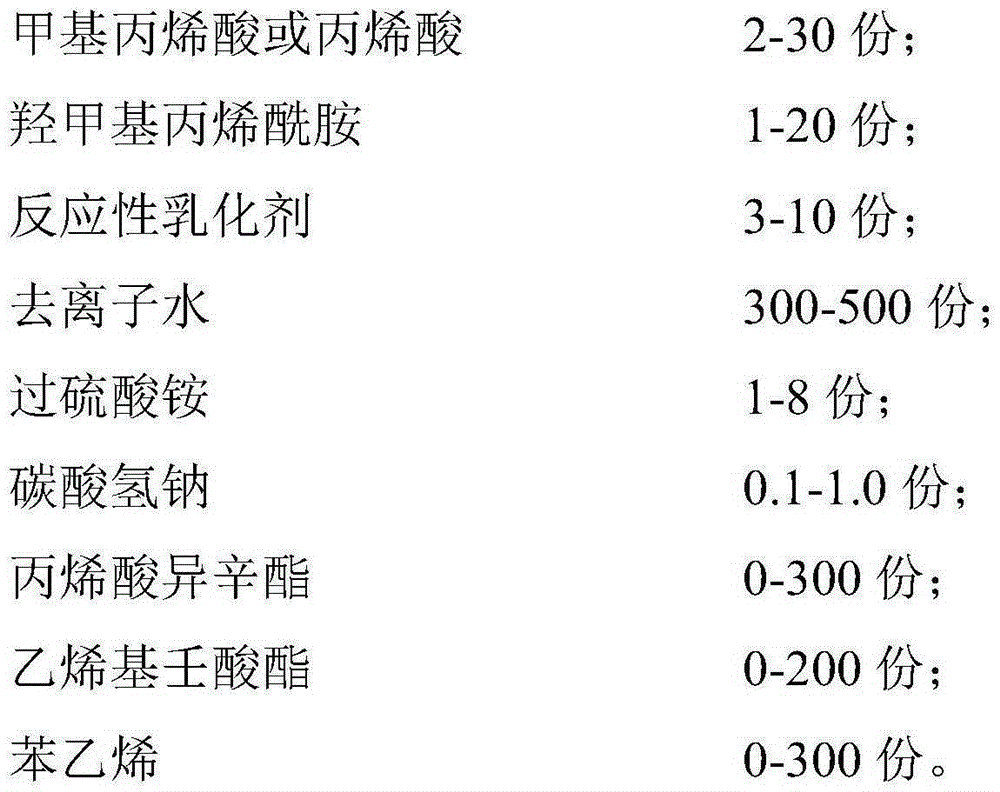

[0036] Water-based adhesives include by parts:

[0037]

[0038] The preparation method of the above-mentioned water-based adhesive with water whitening resistance comprises:

[0039] S1: Preparation of pre-emulsion: Add 2.4 parts of alkyl ether sulfate allylamine salt and 0.08 part of sodium bicarbonate to the pre-emulsification tank, mix with 150 parts of deionized water and stir evenly, and add 2 parts of Methacrylic acid, 20 parts of methylol acrylamide, 300 parts of isooctyl acrylate, and 150 parts of styrene are stirred evenly to obtain a pre-emulsion;

[0040] S2: Add 300 parts of deionized water, 0.6 parts of allylamine alkyl ether sulfate and 0.02 parts of sodium bicarbonate into the reaction kettle; heat up to 75-85 ° C, take the pre-emulsified prepared in step S1 Add 1% of the solution, and add 1.5 parts of ammonium persulfate and 15 parts of deionized water mixture;

[0041] S3: keep warm for 10 minutes, start to drop the pre-emulsion prepared in the remaining...

Embodiment 2

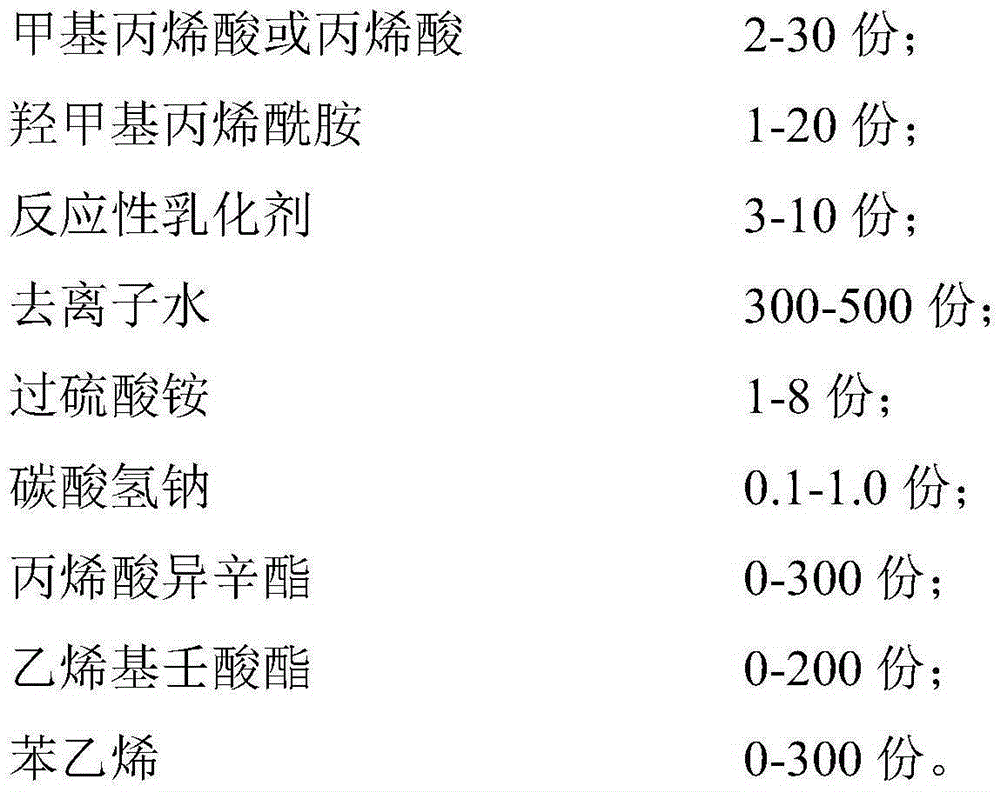

[0043] Water-based adhesives include by parts:

[0044]

[0045] The preparation method of the water-based adhesive with water whitening resistance comprises:

[0046] S1: Preparation of pre-emulsion: 7.25 parts of alkyl ether sulfate allylamine salt and 0.9 part of sodium bicarbonate added to the pre-emulsification kettle were mixed with 150 parts of deionized water and stirred evenly, and 20 parts of acrylic acid, 10 parts of methylol acrylamide, 150 parts of isooctyl acrylate, 100 parts of vinyl nonanoate and 50 parts of styrene are stirred evenly to obtain a pre-emulsion;

[0047] S2: Add 200 parts of deionized water, 0.75 parts of allylamine alkyl ether sulfate and 0.1 part of sodium bicarbonate into the reaction kettle; heat up to 85 ° C, take 5 parts of the pre-emulsion prepared in step S1 % was added, and a dilution solution of 4.2 parts of ammonium persulfate and 20 parts of deionized water was added;

[0048] S3: keep warm for 10 minutes, start to drop the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com