High-stability silicon rubber latex or emulsion and preparation method thereof

A high-stability, silicone rubber technology, applied in the field of new organic silicon chemical materials, can solve the problems of unsustainable slippery feeling, loss of slippery feeling, unstable emulsion stabilization effect, etc., and achieve the effect of increasing the viscosity of the internal phase and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

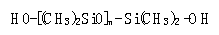

Image

Examples

Embodiment 1

[0022] At room temperature, add 2910g D4 (octamethylcyclotetrasiloxane) and 90g dodecylbenzenesulfonic acid into a 5000ml heatable stainless steel or glass reaction vessel with stirring, stir and heat to 60~120℃, Keep stirring within this temperature range for 1~2 hours, then stop heating and stirring, and leave it at room temperature for 48 hours to obtain a viscosity (25°C) of 10 6 ~10 7 Mpa.s high viscosity silicone rubber and dodecylbenzenesulfonic acid mixture. Transfer the high-viscosity silicone rubber and dodecylbenzenesulfonic acid mixture prepared above into a 5000ml kneader or a planetary mixer, add 300g triethanolamine dodecylbenzenesulfonate, 600g deionized water or distilled water under stirring, and mix for 30 After ~60min, add triethanolamine dropwise (or flow-feed) to the mixture at a uniform speed within 60~90 minutes, stir while adding dropwise, stop dropping when the pH value of the mixture is 7~8, and continue stirring for no less than 2 hours Stop stir...

Embodiment 2

[0026] Same as Example 1, except that 2910 g of D4 (octamethylcyclotetrasiloxane) is changed to DMC (hexamethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, decamethyl Cyclopentasiloxane mixture) 2850g, 90g of dodecylbenzenesulfonic acid was changed to 150g, standing for 48h was changed to standing for 120h, dodecylbenzenesulfonic acid triethanolamine was changed from 150g to 450g, and isomerized deca 150g of triol polyoxyethylene (5) ether, 150g of isomeric tridecyl alcohol polyoxyethylene (10) ether, 600g of deionized water or distilled water was changed to 900g, and the other was unchanged, 4725g of gelatinous semi-solid content of 81% was obtained. Transparent water-in-oil type high-viscosity silicone rubber latex or emulsion invention A2;

[0027] Take 1000g of this invention A2, add appropriate amount of deionized water or distilled water and stir it evenly with a strong mixer, make it phase inversion into milky white oil-in-water emulsion with a solid content of 50%...

Embodiment 3

[0030] With embodiment 1, just change D4 into 2880g, dodecylbenzenesulfonic acid is changed into 120g, after dodecylbenzenesulfonate triethanolamine 150g is changed into 360g, then add isomerism tridecyl alcohol polyoxyethylene ( 5) Ether 180g, isotridecyl alcohol polyoxyethylene (10) ether 180g, and deionized water or distilled water 600g was changed to 750g, and other things remained unchanged, to obtain 4620g of gel-like transparent water-in-oil type high Viscosity Silicone Rubber Latex or Emulsion Invention A3;

[0031] Take 1000g of the invention A3, add an appropriate amount of deionized water or distilled water therein and stir it evenly with a strong mixer to make it phase invert into a milky white oil-in-water emulsion with a solid content of 50%, which is recorded as the invention A350; take an appropriate amount of A350 with water (this It can be dilute directly with tap water) to a solid content of 1% and shake well to record as the diluted invention A301.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com