Method for recovering erythritol from erythritol crystallization mother liquor

A technology of erythritol and crystallization mother liquor, applied in the field of erythritol extraction, can solve the problems of high cleaning agent cost, increase production cost, reduce membrane flux and the like, achieve good impurity removal effect, simplify production process, and achieve high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1 pretreatment: Dilute the erythritol crystallization mother liquor with pure water to obtain a 30% dilution of Brix;

[0019] Step 2 ceramic membrane filtration: filter the above diluted solution with a ceramic membrane with a separation pore size of 20nm, the working temperature is 25-40°C, and the pressure is 0.1-0.5Mpa to obtain a ceramic filter membrane dialysate, the dialysate Brix is 25%. Luminosity is 12%;

[0020] Step 3 nanofiltration filtration: the ceramic membrane dialysate obtained in step 2 is subjected to nanofiltration filtration with a nanofiltration membrane with a molecular weight cut-off of 150-350 Daltons, and the working temperature of the nanofiltration filtration is 25-35° C., and the pressure is 1.5 ~2.5Mpa, get the nanofiltration dialysate, the Brix of the nanofiltration dialysate is 11%, the transmittance is 98%, and the content of erythritol is 80%;

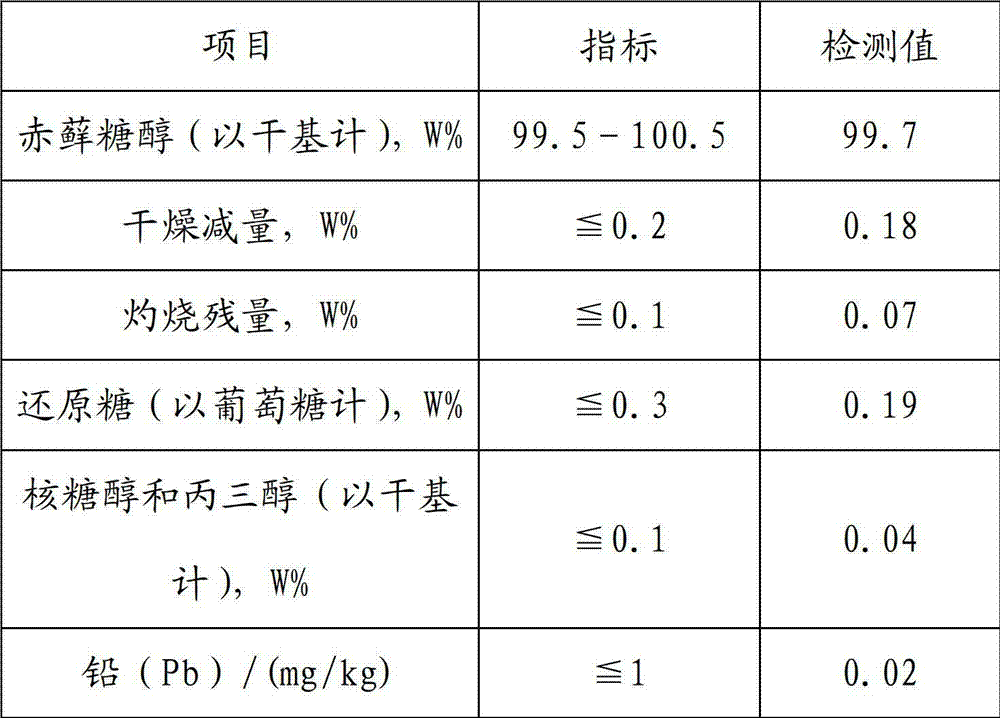

[0021] Step 4 Concentration and crystallization: the above-mentioned nanofiltration...

Embodiment 2

[0024] Step 1 pretreatment: Dilute the erythritol crystallization mother liquor with pure water to obtain a 50% dilution of Brix;

[0025] Step 2 ceramic membrane filtration: filter the above diluted solution with a ceramic membrane with a separation pore size of 50nm, the working temperature is 25-40°C, and the pressure is 0.1-0.5Mpa to obtain a ceramic filter membrane dialysate. The dialysate Brix is 27%. Luminosity is 10%;

[0026] Step 3 nanofiltration filtration: the ceramic membrane dialysate obtained in step 2 adopts a molecular weight cut-off of 150-350 Daltons, and a nanofiltration membrane with a MgSO4 cut-off rate greater than 99%, performs nanofiltration filtration, and the nanofiltration filtration work The temperature is 25-35°C, the pressure is 1.5-2.5Mpa, and the nanofiltration dialysate is obtained. The Brix of the nanofiltration dialysate is 11%, the transmittance is 99.5%, and the content of erythritol is 85%;

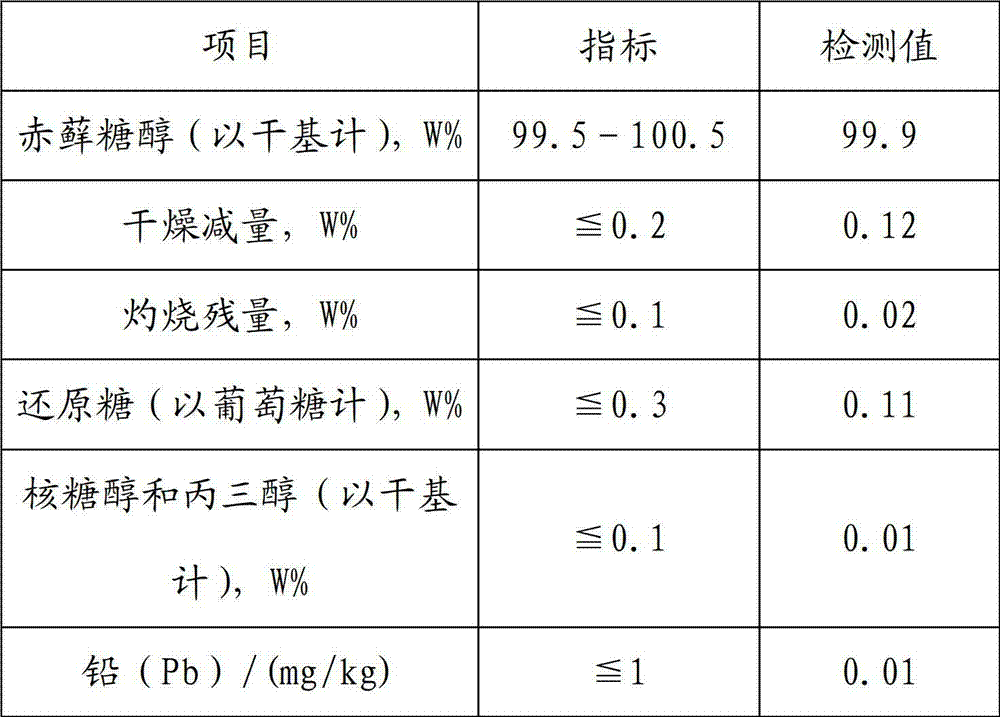

[0027] Step 4 Concentration and crystalliza...

Embodiment 3

[0030] Step 1 pretreatment: Dilute the erythritol crystallization mother liquor with pure water to obtain a 40% dilution of Brix;

[0031] Step 2 ceramic membrane filtration: filter the above diluted solution with a ceramic membrane with a separation pore size of 100nm at a working temperature of 25-40°C and a pressure of 0.1-0.5Mpa to obtain a ceramic filter membrane dialysate, the dialysate Brix is 23%, and the dialysate Luminosity is 9%;

[0032] Step 3 nanofiltration filtration: the ceramic membrane dialysate obtained in step 2 is subjected to nanofiltration filtration with a nanofiltration membrane with a molecular weight cut-off of 150-350 Daltons, and the working temperature of the nanofiltration filtration is 25-35° C., and the pressure is 1.5 ~2.5Mpa, get the nanofiltration dialysate, the Brix of the nanofiltration dialysate is 11%, the transmittance is 94%, and the content of erythritol is 79%;

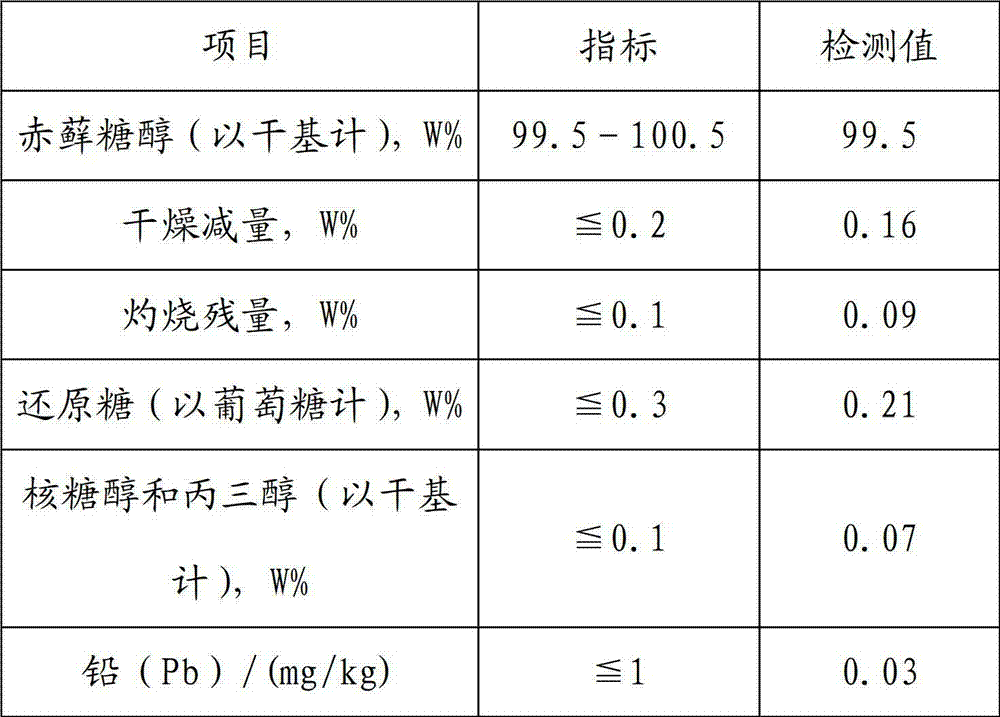

[0033] Step 4 Concentration and crystallization: the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com