Heavy metal stabilizer for bottom mud in aquaculture pond, and manufacturing method and application thereof

A technology of heavy metal stabilizer and pond bottom sludge, which is applied in the agricultural field, can solve the problems of different adsorption and fixation effects of heavy metals, differences in physical and chemical properties, microbial inactivation, etc., and achieve the effect of reducing effectiveness, good effect and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

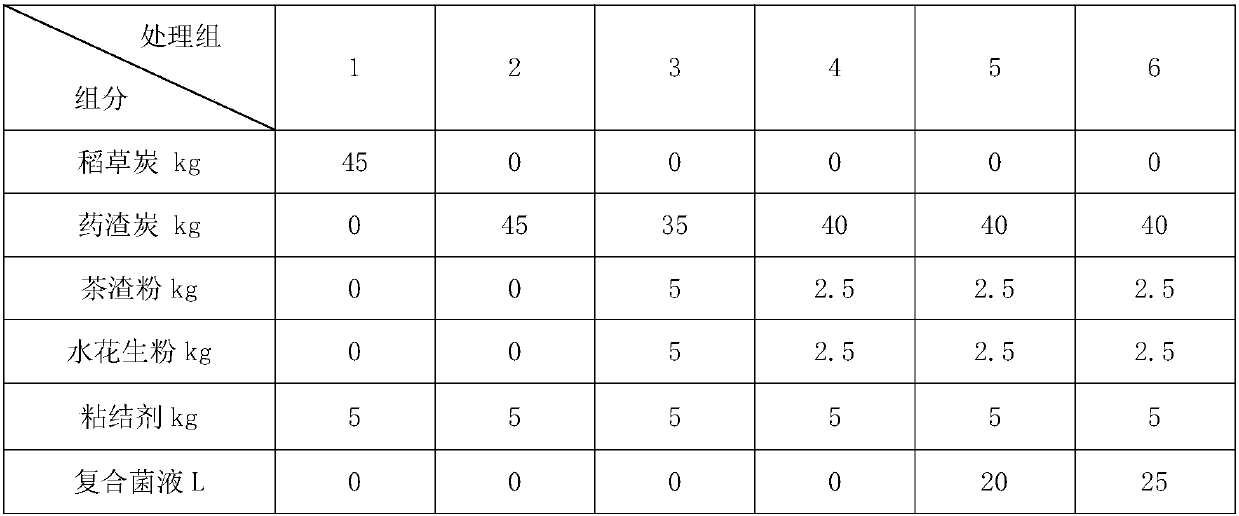

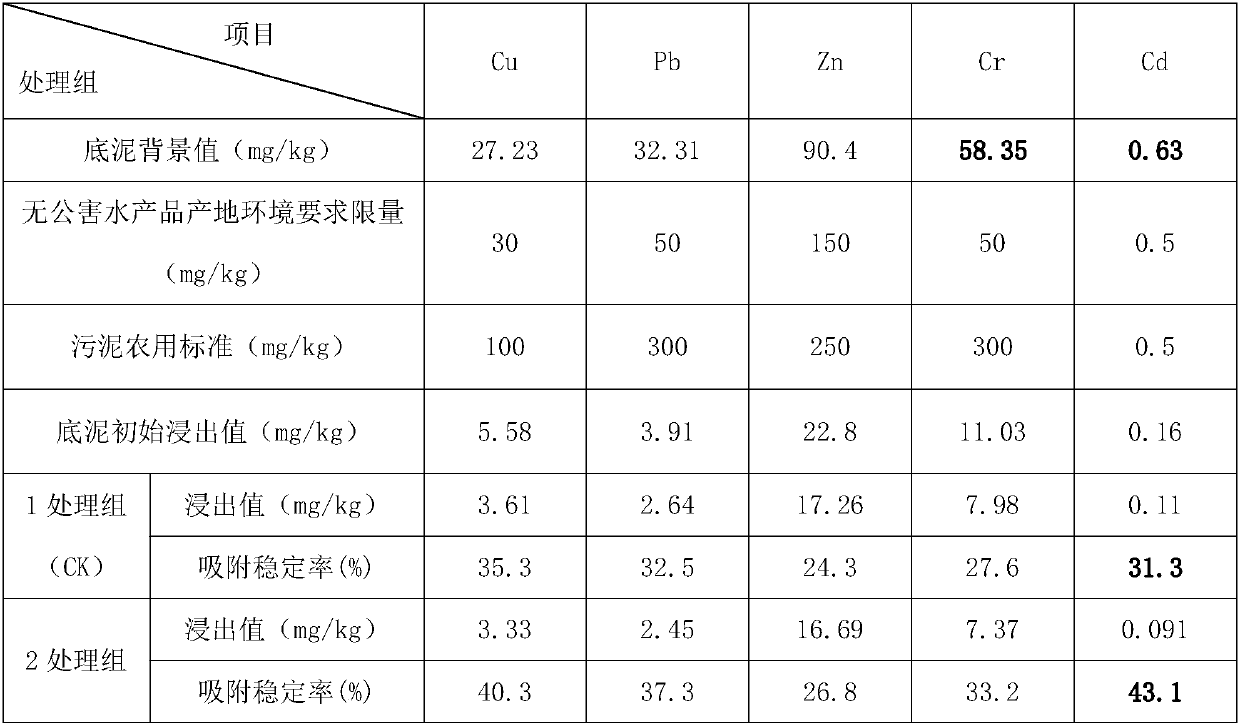

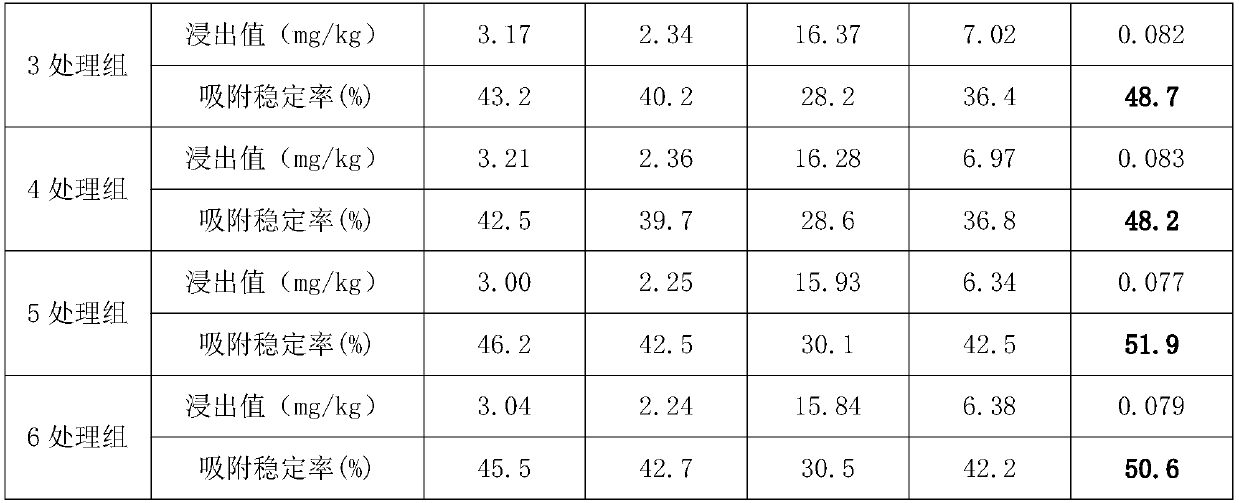

[0043] Embodiment 1, sediment stabilizer component optimization scheme

[0044] 1. Raw material processing:

[0045] Raw materials are processed before each treatment group is formulated

[0046] 1. Preparation of straw biochar: first cut the straw into small sections of 3cm to 5cm, air-dry until the water content is 10% to 12%, use the carbonization furnace, adopt the method of oxygen limitation and slow temperature rise, first pass in nitrogen, and discharge the furnace Inner air, then raised from room temperature to 100°C at a rate of 10°C / min, preheated for 50 minutes to make the raw materials evenly heated, then raised to 600°C, pyrolyzed at a constant temperature for 1.5 hours, taken out, cooled and crushed through an 80-mesh sieve for later use.

[0047] 2. Preparation of Mailuoning medicinal dregs biochar: collect the medicinal dregs of Mailuoning, air-dry until the water content is about 50%, use a pulverizer to crush it into debris less than 3cm, and air-dry until t...

Embodiment 2

[0064] Embodiment 2 Bottom sludge heavy metal stabilizer dosage optimization scheme

[0065] The heavy metal stabilizers prepared by the 5 treatment groups in Example 1 were added to the bottom mud at the ratio of 2%, 3%, 5%, and 10% by mass, and piled up for 7 days at 30°C. , turn the pile every 1d, and take samples on the 7th day to determine the leaching value of heavy metals and the adsorption stability rate. The results are shown in Table 3.

[0066] Table 3 The effect of stabilizer dosage on the leaching value and adsorption stability rate of heavy metals in sediment

[0067]

[0068] The results in Table 3 show that: with the increase of heavy metal stabilizers in the sediment, the leaching value of heavy metals is gradually decreasing, and the adsorption stability rate is gradually increasing. When it increases from 2% to 3%, the heavy metal adsorption stability rate increases significantly. When it reaches 5%, the increase in the heavy metal adsorption stability ...

Embodiment 3

[0069] Example 3, optimization scheme of sediment heavy metal stabilization time

[0070] With the heavy metal stabilizer prepared by 5 treatment groups in Example 1, add the bottom mud in a ratio of 5% (mass ratio), and under the condition of 30°C, pile up 3d, 5d, 7d, 9d respectively, and turn over once every 1d , the sediment samples were taken at 3d, 5d, 7d, and 9d to measure the leaching value and adsorption stability rate of heavy metals in the sediment. The results are shown in Table 4.

[0071] Table 4 Effect of stabilizer action time on heavy metal leaching value and adsorption stability rate of sediment

[0072]

[0073] The results in Table 4 show that as the stacking time increases, the heavy metal adsorption stability rate increases first and then decreases. From 3d to 5d, the heavy metal adsorption stability rate increases significantly. From 5d to 7d, the difference in the increase of heavy metal adsorption rate becomes smaller. From From 7d to 9d, the adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com