Comprehensive extraction and utilization production technology for propolis

A technology of comprehensive extraction and production process, which is applied in the field of production process of comprehensive extraction and utilization of propolis, can solve the problems such as the reduction of the extraction rate of propolis extract, and achieve the effect of low equipment requirements, simple steps, and simplified preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

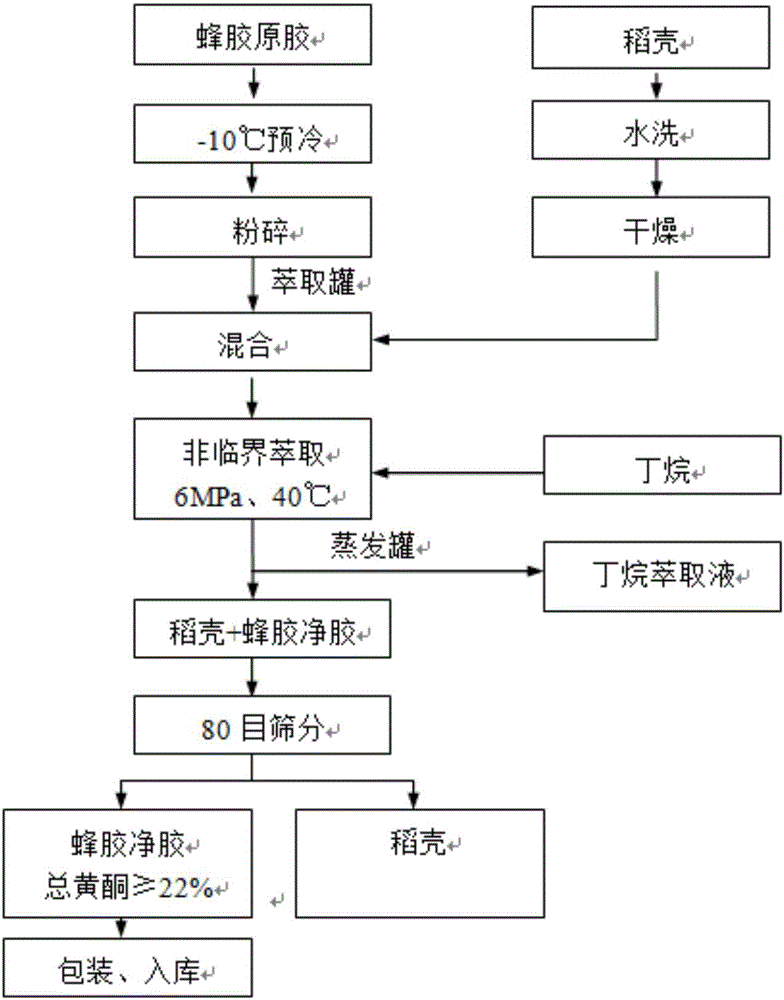

[0043] Example 1 Preparation of propolis net glue

[0044] A preparation process of propolis net glue includes the following steps:

[0045] 1) Pretreatment: Collect 165kg of Brazilian green propolis gel and perform pre-cooling treatment, the pre-cooling temperature is -10 ℃, the pre-cooling time is 12 hours, and then pulverize to obtain propolis particles;

[0046] 2) Mixing: Mix the pretreated propolis particles and rice husk in a weight ratio of 1:4 to obtain a mixture;

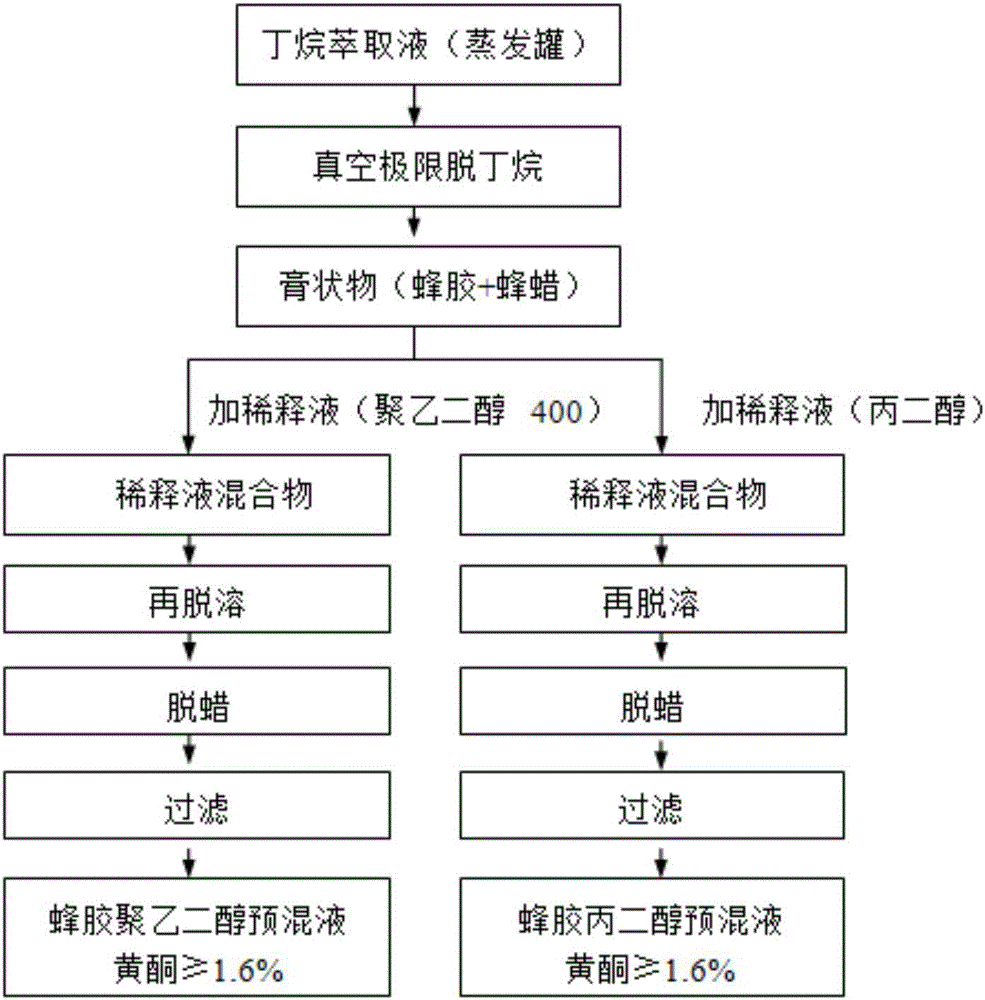

[0047] 3) Non-critical fluid extraction: add n-butane to the mixture for extraction in the extraction tank, the extraction pressure is 6MPa, the temperature is 40°C, and the stirring speed is 30rpm; stand for 60min to obtain the n-butane extract;

[0048] 4) Solid-liquid separation: the n-butane extract is transferred to the evaporation tank for evaporation, and the propolis net glue and rice husk with propolis net glue are left in the extraction tank;

[0049] 5) Screening: Sieve the net propolis and the rice husk w...

Embodiment 4

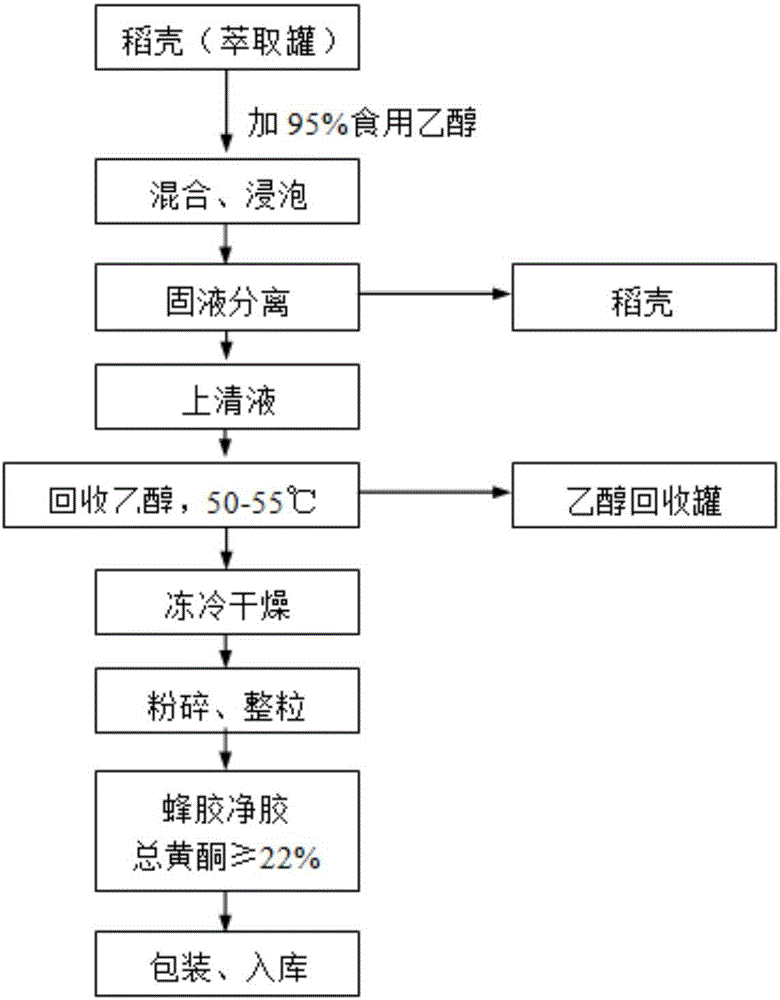

[0062] Example 4 Preparation of freeze-dried propolis powder

[0063] 1) Soaking: The rice husk with propolis gel obtained in step 5) of Example 1 was added with 95% food grade ethanol at a solid-to-liquid ratio of 1:5 while stirring, soaking for 12 hours at a stirring speed of 40 rpm to obtain a solid Liquid mixture

[0064] 2) Solid-liquid separation: The solid-liquid mixture is sieved with an 80-mesh sieve, the rice husks are removed and collected, and the supernatant is left in the extraction tank and allowed to stand for 4-6 hours. The supernatant is heated to obtain a semi-fluid leaching 75kg of paste and recovery of food grade ethanol at the same time; heating temperature is 50℃; pressure in extraction tank is -0.1MPa;

[0065] 3) Freeze-drying: vacuum freeze-drying the semi-fluid extract to obtain freeze-dried propolis powder particles, which are divided into three stages: pre-cooling treatment, freezing treatment, and heating treatment; the pre-cooling temperature is -18°C,...

Embodiment 5

[0067] Example 5 Preparation of propolis lyophilized powder

[0068] 1) Soaking: The rice husk with propolis gel obtained in step 5) of Example 2 was added with 95% food grade ethanol at a solid-to-liquid ratio of 1:8 while stirring, soaking for 16 hours, and stirring at 30 rpm to obtain a solid Liquid mixture

[0069] 2) Solid-liquid separation: The solid-liquid mixture is sieved with an 80-mesh sieve, the rice husks are removed and collected, and the supernatant is left in the extraction tank and allowed to stand for 4-6 hours. The supernatant is heated to obtain a semi-fluid leaching 69kg of paste and recovery of edible ethanol at the same time; heating temperature is 55℃; pressure in extraction tank is -0.9MPa.

[0070] 3) Freeze-drying: vacuum freeze-drying the semi-fluid extract to obtain freeze-dried propolis powder particles, which are divided into three stages: pre-cooling treatment, freezing treatment, and heating treatment; the pre-cooling temperature is -20°C, overnight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com