Carbon-nitrogen alkene photocatalyst and preparation method thereof

A photocatalyst and carbenene technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as unfavorable electron-hole separation, low photocatalytic activity, etc., and achieve high application prospects And the effect of practical value, simple process and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, chemical exfoliation prepares carbazene

[0028] Weigh 2.0g C 3 N 4 Put it in a 50mL beaker, then add 20mL of 98% concentrated sulfuric acid, mix and stir the two at room temperature on an electromagnetic stirrer for 8 hours, then pour the mixed liquid into a beaker with 100mL deionized water for dilution. Put it into a centrifuge tube for centrifugation, and the precipitate obtained after centrifugation is washed several times with deionized water until the pH is close to neutral, then transferred to a petri dish, placed in a constant temperature oven, and dried at 80°C. The finally obtained white solid powder is For carbon nitrogen.

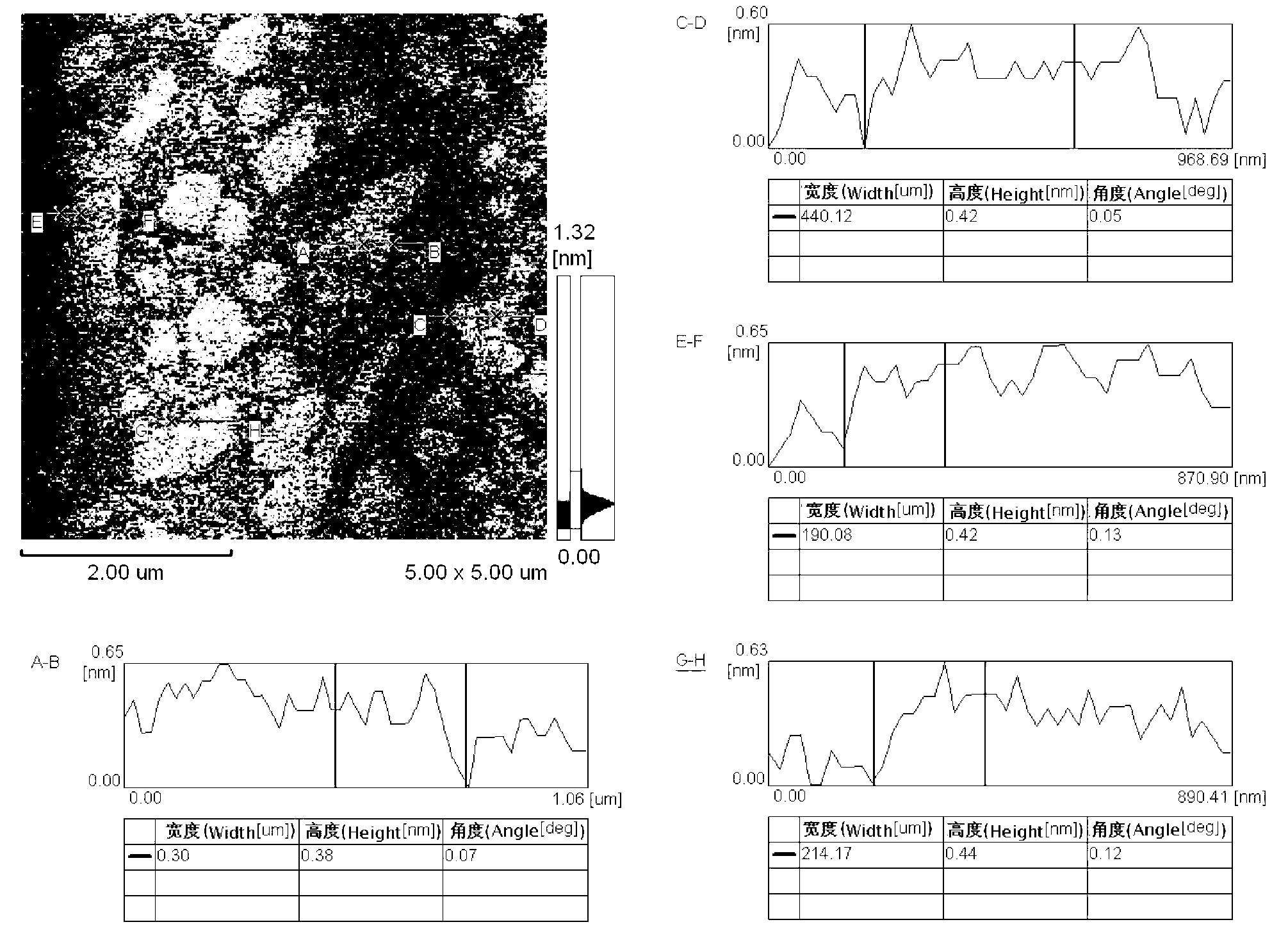

[0029] The structural test of the carbazene prepared in this embodiment was carried out on a German Bruker D8Advance X-ray diffractometer (XRD) (CuKα ray, λ=0.154nm, voltage 40kV, current 40mA), and its XRD pattern is as follows figure 1 shown. Depend on figure 1 It can be seen that C 3 N 4 The 100 crystal plane on t...

Embodiment 2

[0036] Embodiment 2, the photoelectric performance test of carbonitrone

[0037] (1) Preparation of carbon nitrogen film electrode

[0038] Ultrasonic disperse 2 mg of carbazene powder in 1 mL of water, make a slurry, and spread it on a 4 cm × 2 cm ITO conductive glass by dip coating method. After the sample is dried, it is heated at 200°C for 5 hours to make a thin film electrode, and the film has a certain mechanical strength by heating.

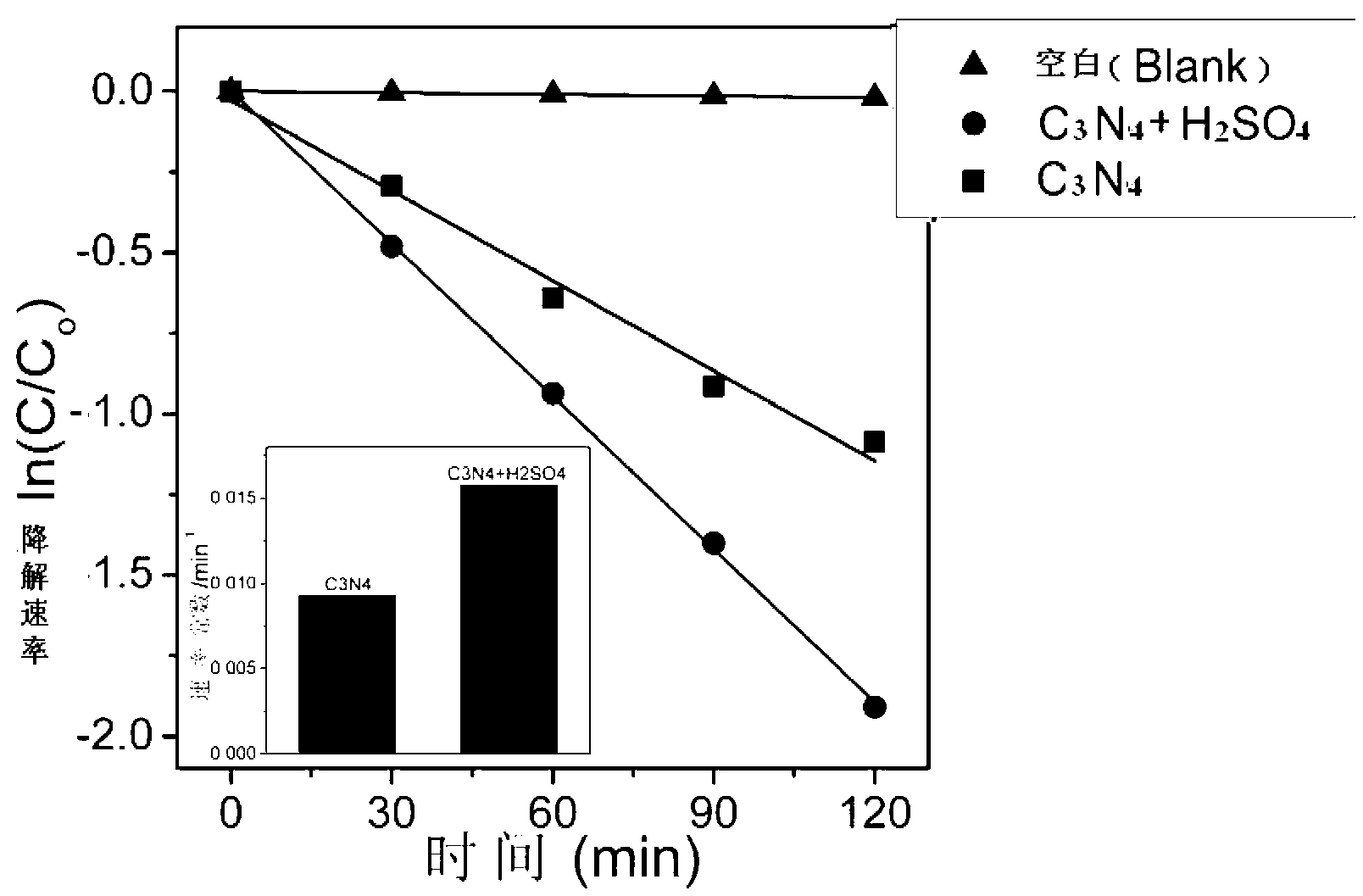

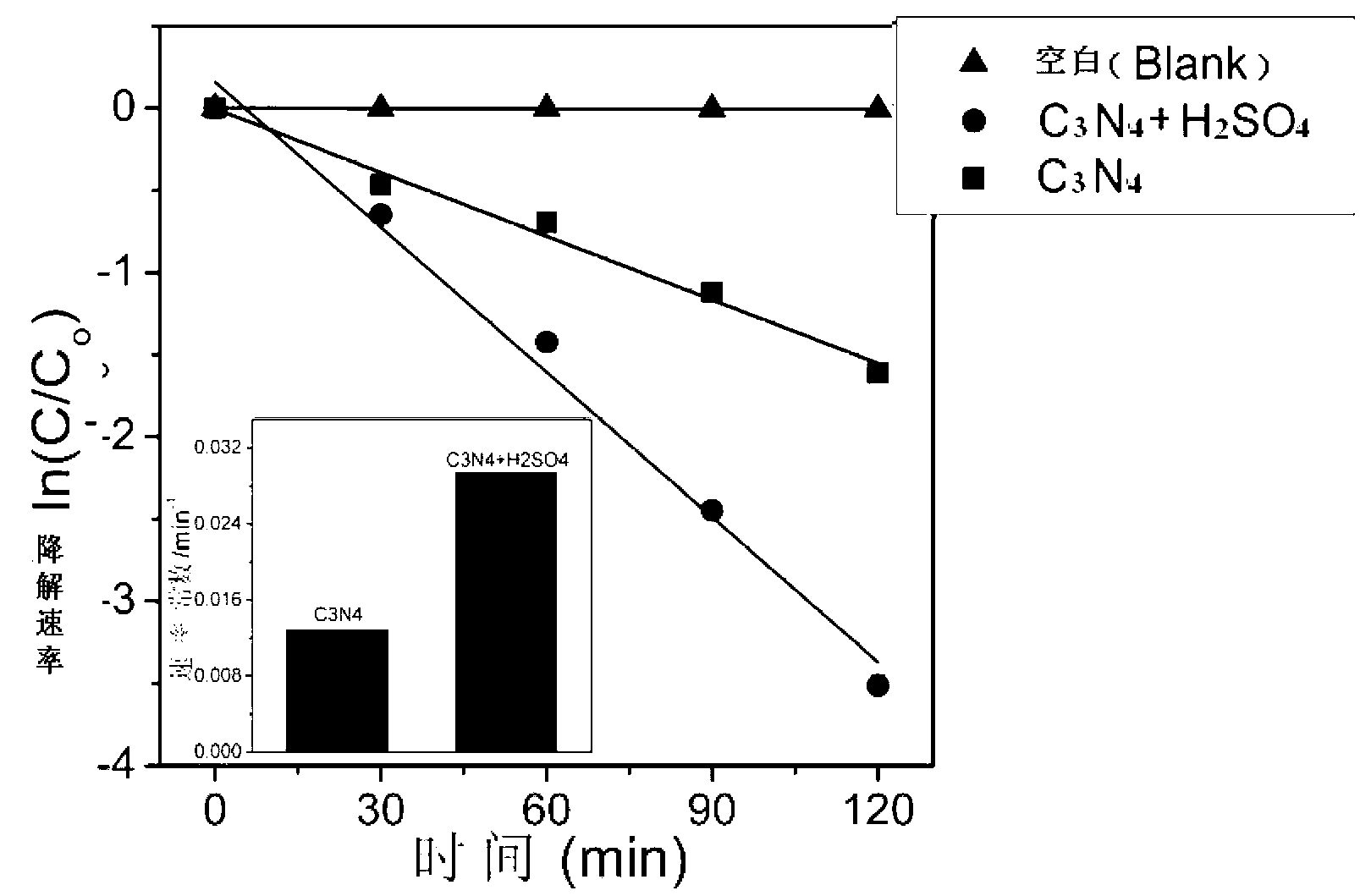

[0039] (2) Evaluation of photoelectric properties of carbonitrone

[0040] Use methylene blue dye (MB) as the target degradation product, and the initial concentration in 100mL is 1*10 -550mg of photocatalyst was added to mol / L MB solution, and the catalytic activity of carbazene photocatalyst was investigated under the irradiation of ultraviolet light and visible light. The ultraviolet light adopts 11W low-pressure mercury lamp, the main wavelength is 254nm, and the light intensity is 0.9mW / cm 2 . Visible light uses a 500W xenon lamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com