Hydroxyl polyether-terminated polydimethylsiloxane and blue light emulsion of hydroxyl polyether-terminated polydimethylsiloxane as well as preparation method of blue light emulsion

A technology of polydimethylsiloxane and hydroxy polyether, which is applied in textiles, papermaking, fiber processing, etc., can solve the problems of compatibility to achieve softness and smoothness, short process pot life, and inability to achieve non-bleaching oil, etc. To achieve wide compatibility, high solid content, to achieve the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

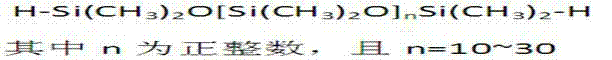

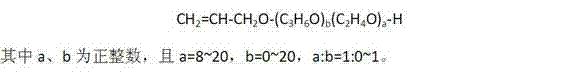

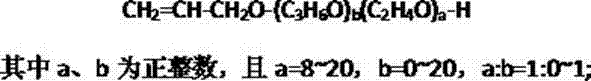

[0030] At room temperature, in a 2000ml electric stirring glass reactor, add 1160g number average molecular formula: CH 2 =CH-CH 2 O-(C 3 h 6 O) 5 (C 2 h 4 O) 15 -H's acryl polyether (alkenyl mole number 1.15mol) and 807g number average molecular formula is: H-Si(CH 3 ) 2 O[Si(CH 3 ) 2 O] 20 Si(CH 3 ) 2-H hydrogen-terminated polydimethylsiloxane (the number of moles of hydrogen groups is 1mol, the number of moles of alkenyl groups: the number of moles of hydrogen groups = 1.15:1), and after starting to stir, add 1~2g of speier catalyst (the mass of chloroplatinic acid The content is 1%), stirring to raise the temperature to 120~150°C and stirring for 1~3 hours until the system is completely transparent and then lowered to room temperature to obtain a transparent medium-low viscosity hydroxyl polyether-terminated polydimethylsiloxane A1. The viscosity measured by a rotary viscometer at 25°C is 800~1000mpa.s.

Embodiment 2

[0032] At room temperature, in a 1000ml electric stirring glass reactor, add 550g number average molecular formula: CH 2 =CH-CH 2 O-(C 2 h 4 O) 10 -H's acryl polyether (alkenyl mole number 1.10mol) and 437g number average molecular formula is: H-Si(CH 3 ) 2 O[Si(CH 3 ) 2 O] 10 Si(CH 3 ) 2 -H hydrogen-terminated polydimethylsiloxane (the number of moles of hydrogen groups is 1mol, the number of moles of alkenyl groups: the number of moles of hydrogen groups = 1.10:1), and after starting to stir, add 0.5~1g of Karstdet catalyst (the mass content of platinum element 0.3%), stirred and heated up to 120~150°C and stirred for 1~3 hours until the system was completely transparent and then lowered to room temperature to obtain transparent and medium-low viscosity hydroxyl polyether-terminated polydimethylsiloxane A2. 25 The viscosity measured by ℃ rotary viscometer is 300~500mpa.s.

Embodiment 3

[0034] At room temperature, add 850g D 4 (or DMC) and 150g of A1 of Example 1 (D 4 Or the quality of DMC: the quality of A1=85:15), add 1~3g of alkali gel catalyst (D 4 Or DMC or small molecule hydroxyl silicone oil with hydroxyl content of 6~8% and KOH are stirred and reacted at 130~160°C for 0.5~3h until the system is transparent, and KOH accounts for 10% of the total mass of the reactants), and the temperature is raised to 120~150°C, Equilibrate the telomerization reaction under stirring for 5-8 hours, then stop heating and stirring, and the reactant naturally cools down to room temperature to obtain milky white to milky yellow medium-high viscosity polydimethylsiloxane B1 terminated with hydroxyl polyether. Rotate at 25°C The viscosity measured by the type viscometer is 30000~40000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com