Preparation method of graphene based on ascorbic acid

A technology of ascorbic acid and graphene, applied in the field of preparation of nanomaterial technology, can solve problems such as harm to people and the environment, and achieve the effect of shortening reaction time and being beneficial to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

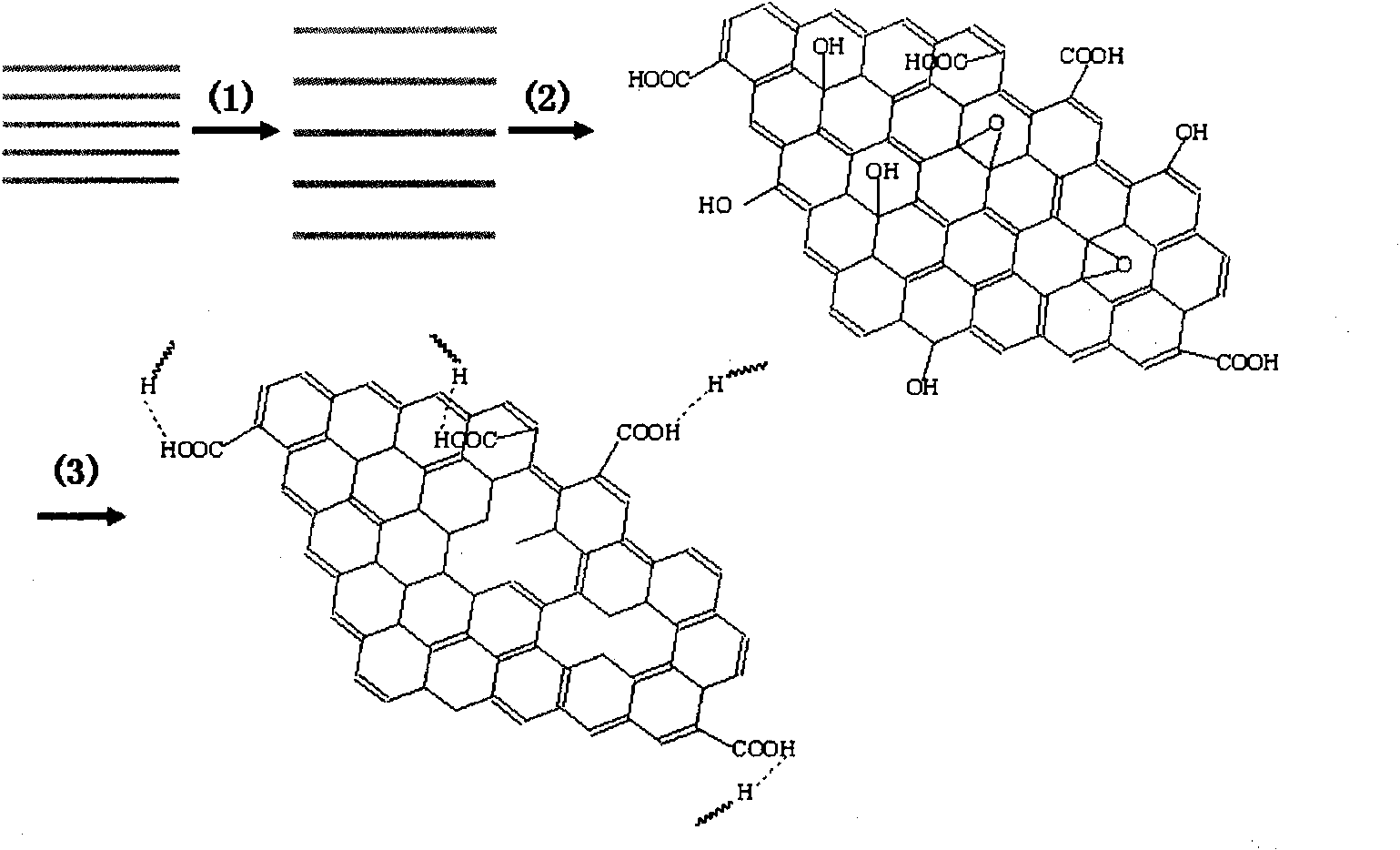

[0029] Such as figure 1 As shown, the preparation method described in this embodiment comprises the following steps:

[0030] 1. At room temperature, add 2g of 500-mesh granular natural graphite and 1g of sodium nitrate into a 250mL three-necked flask and cool to 0°C; then, slowly add 50mL of concentrated sulfuric acid into the three-necked flask and fully stir for 30 minutes while maintaining the temperature of the reaction system Not higher than 5°C; then add 0.3 grams of potassium permanganate into the there-necked flask and stir fully for 30 minutes, while keeping the temperature of the reaction system not higher than 10°C; within 1 hour, divide 7 grams of potassium permanganate into 3 Add batches into the three-necked flask, and keep the temperature of the reaction system not higher than 20°C. Finally, the cold bath was removed, and the temperature of the reaction system was heated to 35±3° C. with a water bath, and stirred thoroughly for 2 hours to obtain a brown graphi...

Embodiment 2

[0035] 1. At room temperature, add 2g of 500-mesh granular natural graphite and 1g of sodium nitrate into a 250mL three-necked flask and cool to -5°C; then, slowly add 50mL of concentrated sulfuric acid into the there-necked flask and stir for 30 minutes, and keep the temperature of the reaction system The temperature is lower than 0°C; then add 0.3 grams of potassium permanganate into the three-necked flask and stir it fully for 30 minutes, while keeping the temperature of the reaction system not higher than 5°C; within 1 hour, divide 7 grams of potassium permanganate into 3 Add batches into the three-necked flask, and keep the temperature of the reaction system not higher than 15°C. Finally, the cold bath was removed, and the temperature of the reaction system was heated to 35±3° C. with a water bath, and stirred thoroughly for 2 hours to obtain a brown graphite suspension.

[0036] 2. Slowly add 90mL deionized water into the three-necked flask, the temperature of the system...

Embodiment 3

[0040] 1. Preparation of graphite oxide: At room temperature, add 2 g of 500-mesh granular natural graphite and 1 g of sodium nitrate into a 250 mL three-necked flask and cool to -10°C; then, slowly add 50 mL of concentrated sulfuric acid into the three-necked flask and stir for 30 minutes. And keep the temperature of the reaction system lower than -5°C; then add 0.3 grams of potassium permanganate into the three-necked flask and fully stir for 30 minutes, while keeping the temperature of the reaction system not higher than 0°C; within 1 hour, add 7 grams of potassium permanganate Potassium manganate was added into the three-necked flask in 3 batches, and the temperature of the reaction system was kept not higher than 10°C. Finally, the cold bath was removed, and the temperature of the reaction system was heated to 35±3° C. with a water bath, and stirred thoroughly for 2 hours to obtain a brown graphite suspension.

[0041] 2. Slowly add 90mL deionized water into the three-nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com