Microemulsion cutting fluid, cutting diluent and preparation and application methods of microemulsion cutting fluid

A cutting fluid and micro-emulsification technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor antibacterial performance and rapid pH drop, and achieve the effects of excellent antibacterial performance, long service life and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of microemulsion cutting fluid, it may further comprise the steps:

[0043] (1) Heat 22.0 parts of paraffin-based mineral oil to 40°C, add 2.0 parts of sodium petroleum sulfonate, 5.0 parts of fatty alcohol polyoxyethylene ether, 8.0 parts of oleic acid, 10.0 parts of chlorinated paraffin and 3.0 parts of diethylene glycol monobutyl ether, stirred at a speed of 200 rpm for 30 minutes until uniformly stirred to obtain a mixed solution;

[0044] (2) At room temperature, add 4.0 parts of boric acid amine salt, 6.0 parts of boric acid amide, 0.2 part of benzotriazole, 38.7 parts of water, 1.0 part of benzisothiazolin-one and 0.1 part of emulsified silicone oil into the mixed solution , Stir at a speed of 200rpm for 30min until the mixture is evenly stirred.

[0045] The microemulsified cutting fluid can be diluted 10-40 times according to specific conditions.

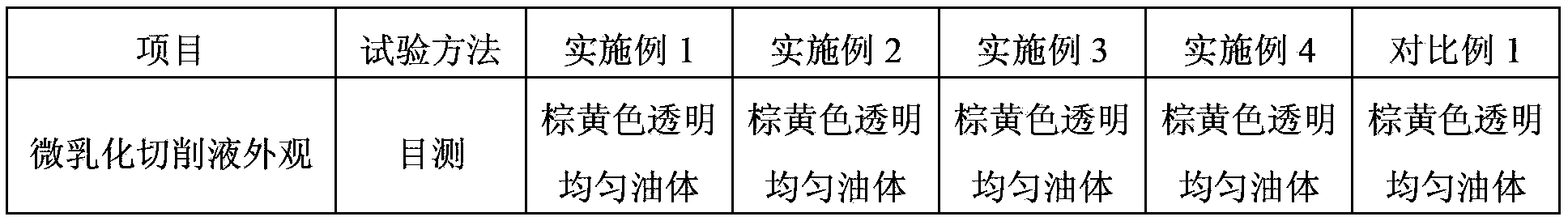

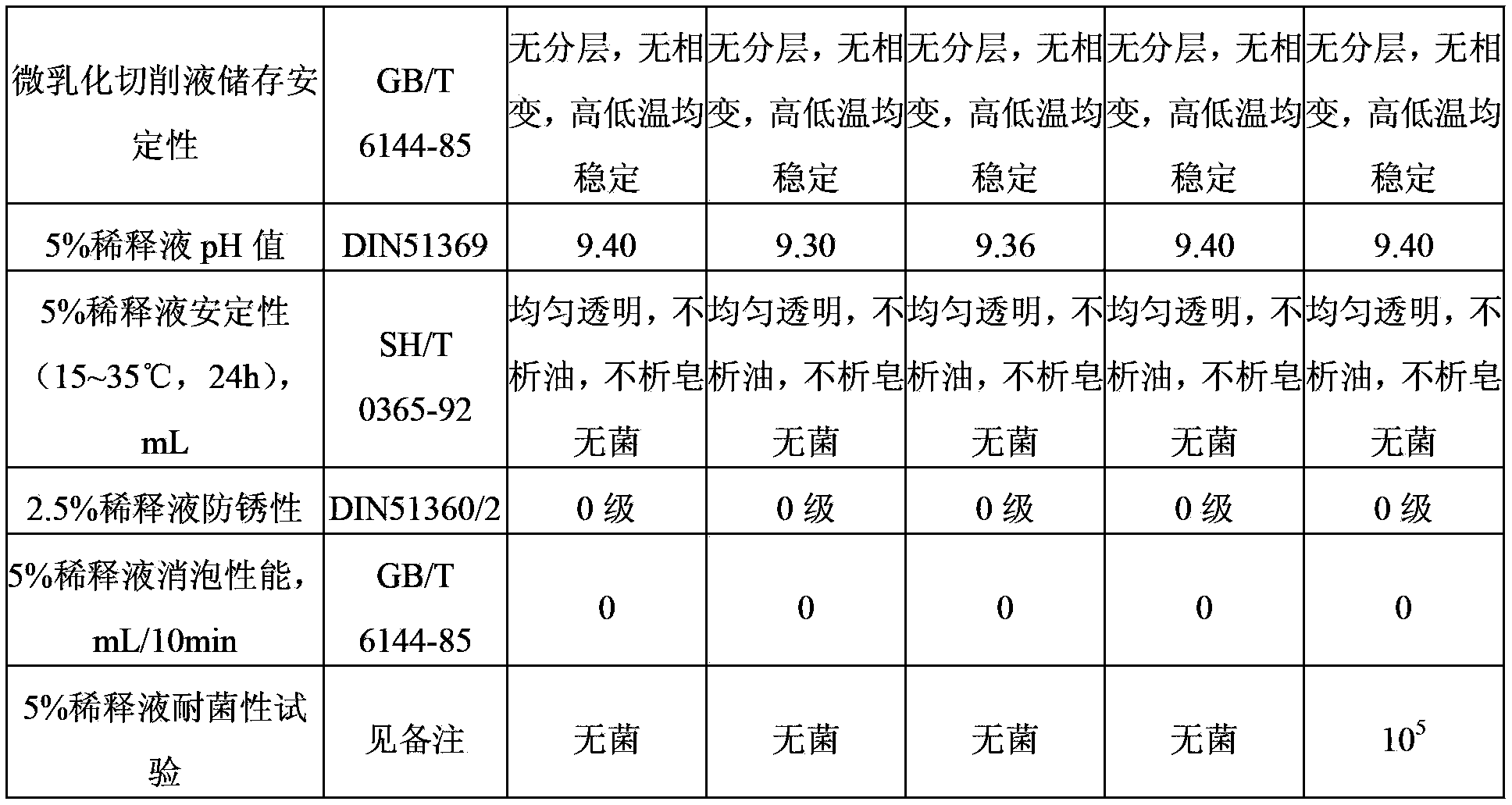

[0046] The performance testing data of the microemulsion cutting fluid are shown in Table...

Embodiment 2

[0048] The preparation method of microemulsion cutting fluid, it may further comprise the steps:

[0049] (1) Raise 25.0 parts of naphthenic mineral oil to 50°C, add 10.0 parts of sodium petroleum sulfonate, 3.0 parts of fatty alcohol polyoxyethylene ether, 10.0 parts of tall oil fatty acid, chlorinated 8.0 parts of paraffin and 3.0 parts of diethylene glycol monobutyl ether were stirred at a speed of 180 rpm for 25 minutes until uniformly stirred to obtain a mixed solution;

[0050] (2) At room temperature, add 8.0 parts of boric acid amine salt, 0.2 parts of benzotriazole, 31.7 parts of water, 1.0 part of Cathone and 0.1 part of emulsified silicone oil into the mixture, and stir at 180 rpm for 25 minutes until uniform , that is.

[0051] The microemulsified cutting fluid can be diluted 10-40 times according to specific conditions.

[0052] The performance testing data of the microemulsion cutting fluid are shown in Table 1.

Embodiment 3

[0054] The preparation method of microemulsion cutting fluid, it may further comprise the steps:

[0055] (1) Heat 28.0 parts of paraffin-based mineral oil to 40°C, add 5.0 parts of sodium petroleum sulfonate, 5.0 parts of alkylphenol polyoxyethylene ether, and 5.0 parts of trimethylolpropane oleate into the paraffin-based mineral oil in sequence , 5.0 parts of chlorinated paraffin and 2.0 parts of diethylene glycol monobutyl ether, stirred at a speed of 220 rpm for 35 minutes until evenly stirred to obtain a mixed solution;

[0056] (2) At room temperature, add 2.0 parts of boric acid ester, 3.0 parts of boric acid amine salt, 0.3 parts of benzotriazole, 41.5 parts of water, 3.0 parts of kasone and 0.2 parts of emulsified silicone oil into the mixed solution, and use 220rpm Stir at a high speed for 35 minutes until the mixture is evenly stirred.

[0057] The microemulsified cutting fluid can be diluted 10-40 times according to specific conditions.

[0058] The performance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com