Water-based ceramic three-dimensional pattern printing ink and preparation method thereof

A technology for printing inks, ceramics, applied in the direction of reproduction/marking methods, printing, inks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

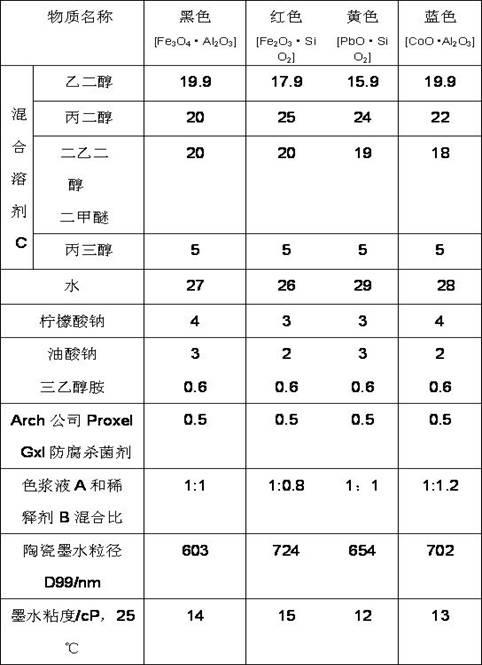

[0042] 1. Prepare black, yellow, red and blue color paste A according to the formula listed in Table 1. Add dispersant, defoamer, resin, etc. to the mixed solution containing water and propylene glycol and stir evenly, then pre-process with a high-speed mixer. Disperse to make the color paste have a certain fluidity, and then transfer the pre-dispersed color paste to a sand mill for grinding until the particle size D50: 200~350nm and the maximum particle size is ≤800nm; after grinding, the color paste A Filter with a 1 micron filter element to obtain a uniform and stable color paste A.

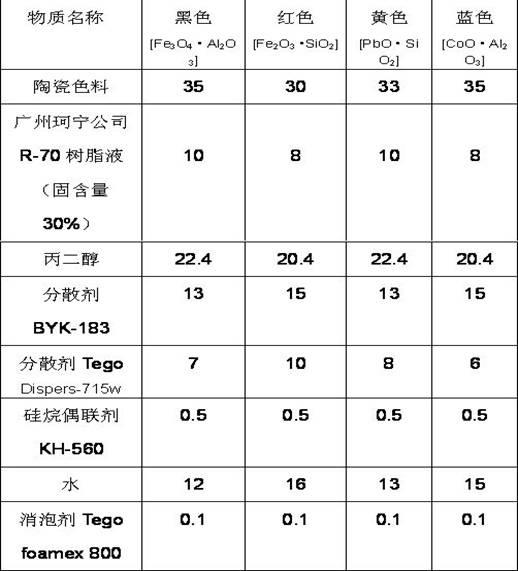

[0043] 2. Prepare diluent B according to the formula listed in Table 2, and mix according to the corresponding ratio of colorant liquid A and diluent B, mix thoroughly in a high-speed mixer, then ultrasonically disperse for 1 hour, and filter to obtain water-based ceramic three-dimensional pattern printing Ink products.

[0044]

[0045] [0023] Table 1 Color paste A formula (weight %)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com