Flame-retardant microcapsule as well as preparation method and application thereof

A microcapsule and flame-retardant technology, applied in the direction of microcapsule preparation, microsphere preparation, adhesive additives, etc., can solve the problems of reducing the physical and mechanical properties of materials, affecting the life of electronic components, and reducing the adhesion of potting adhesives, etc., to achieve Good coating effect, low saturated vapor pressure, good thermoplasticity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

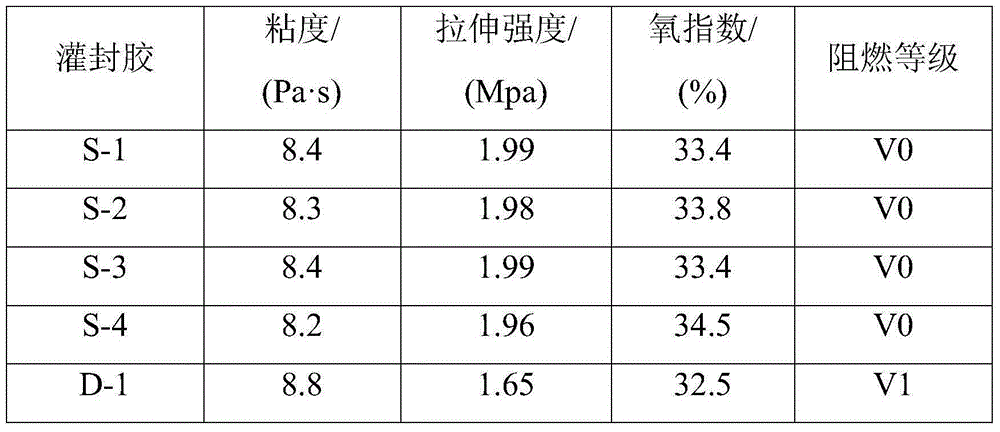

Examples

Embodiment 1

[0028] A flame-retardant microcapsule, whose core material is liquid heptafluoropropane, and whose cladding layer is polymethyl methacrylate polymer. Its preparation method is as follows:

[0029] a, 600g gaseous heptafluoropropane is passed into the pressurized reactor at room temperature, and the pressurized pressure is controlled to 4Mpa, so that heptafluoropropane is converted into a liquid state;

[0030] b. Add 300g of water, 150g of polyvinyl alcohol solution with a mass fraction of 1%, and 8g of sodium dodecylsulfonate to the liquid heptafluoropropane in the pressurized reactor, stir and heat to 50°C to 55°C;

[0031] c. Add 0.6g initiator BPO to 100g methyl methacrylate to dissolve, then slowly drop into the reaction solution of step b; after the dropwise addition, adjust the stirring speed to 200rmp / min, after constant stirring speed, control the suspension polymerization reaction The temperature is 78±2°C, and the polymerization reaction time is 2 hours; then absor...

Embodiment 2

[0034] A flame-retardant microcapsule, whose core material is liquid hexafluoropropane, and whose cladding layer is polymethyl methacrylate polymer. Its preparation method is as follows:

[0035] a. Pass 800g of gaseous hexafluoropropane into the pressurized reactor at room temperature, and control the pressurized pressure to 5Mpa to make heptafluoropropane into liquid state;

[0036] b. Add 400g of water, 160g of polyvinyl alcohol solution with a mass fraction of 1%, and 9g of OP-10 emulsifier to the liquid hexafluoropropane in the pressurized reactor, stir and heat to 50°C-55°C;

[0037] c. Add 0.8g of initiator BPO to 100g of methyl methacrylate to dissolve, then slowly drop into the reaction solution of step b; after the dropwise addition, adjust the stirring speed to 200rmp / min, after constant stirring speed, control the suspension polymerization reaction The temperature is 78±2°C, and the polymerization reaction time is 2 hours; then absorb a small amount of beads, hard...

Embodiment 3

[0040]A flame retardant microcapsule, the core material is liquid heptafluoropropane, and the coating layer is polymethacrylic acid polymer. Its preparation method is as follows:

[0041] a, 700g gaseous heptafluoropropane is passed into the pressurized reactor at room temperature, and the pressurized pressure is controlled to 5Mpa, so that heptafluoropropane is converted into a liquid state;

[0042] b. Add 500 g of water, 180 g of polyvinyl alcohol solution with a mass fraction of 1%, and 8 g of sodium lauryl sulfate into the liquid hexafluoropropane in the pressurized reactor, stir and heat to 60°C to 65°C;

[0043] c, 0.6g of initiator azobisisobutyronitrile is added to dissolve in 100g of methacrylic acid, and then slowly dripped into the reaction solution of step b; Suspension polymerization reaction temperature 85±2℃, polymerization reaction time 3h; then absorb a small amount of beads, harden after cooling, confirm the end of the reaction; stop stirring, end the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com