Novel polymer anticorrosion painting material

A technology for anti-corrosion coatings and coating materials, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of restricting the development of materials, reducing penetration resistance, and prone to bulges, etc., to achieve good penetration resistance, Effect of preventing corrosion and protecting equipment and spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare polyester polyurethane modified epoxy resin, preparation method is as follows:

[0034] (1) Synthesis of hydroxyl-terminated resin

[0035] Add 12.85kg of trimethylolpropane, 5kg of glycerin, 24.35kg of phthalic anhydride, 4kg of maleic anhydride, and 3kg of xylene into the reaction kettle, start stirring and heat up, when the temperature rises to 120°C, slowly heat up , when the temperature rises to 200°C, keep it warm for 4-6 hours, and measure its acid value and hydroxyl value every 20 minutes. When the acid value is ≤1.0mgKOH / g and the hydroxyl value reaches the specified value of 56±5mgKOH / g, stop heating and start Vacuum to remove the solvent in the resin, cool down and filter to obtain the hydroxyl-terminated resin, which is packaged for later use;

[0036] (2) Synthetic prepolymer

[0037] Add 20kg of TDI into the reactor, start stirring and raise the temperature. When the temperature rises to 40-50°C, add 25kg of hydroxyl-terminated resin and 5kg of N...

Embodiment 2

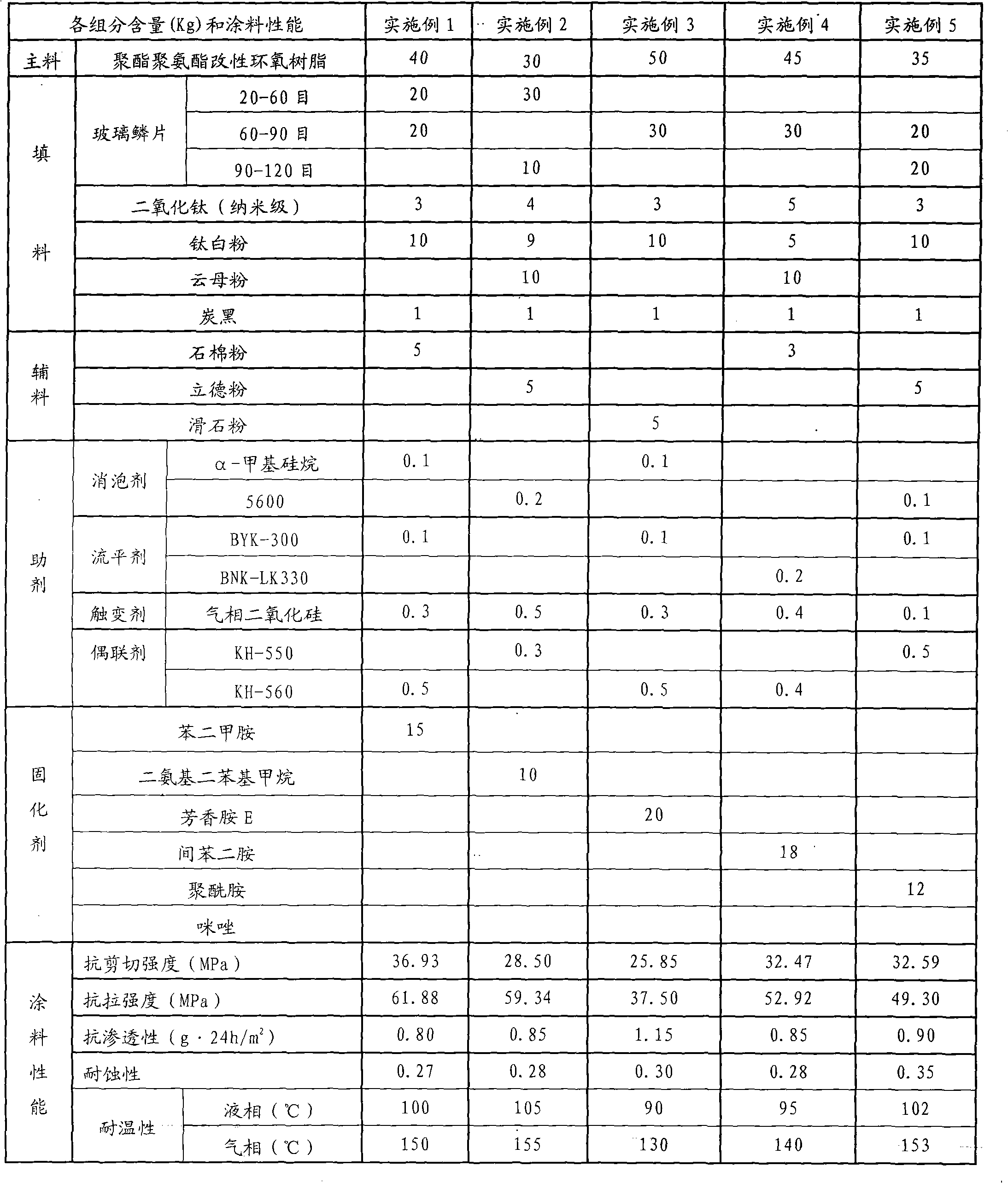

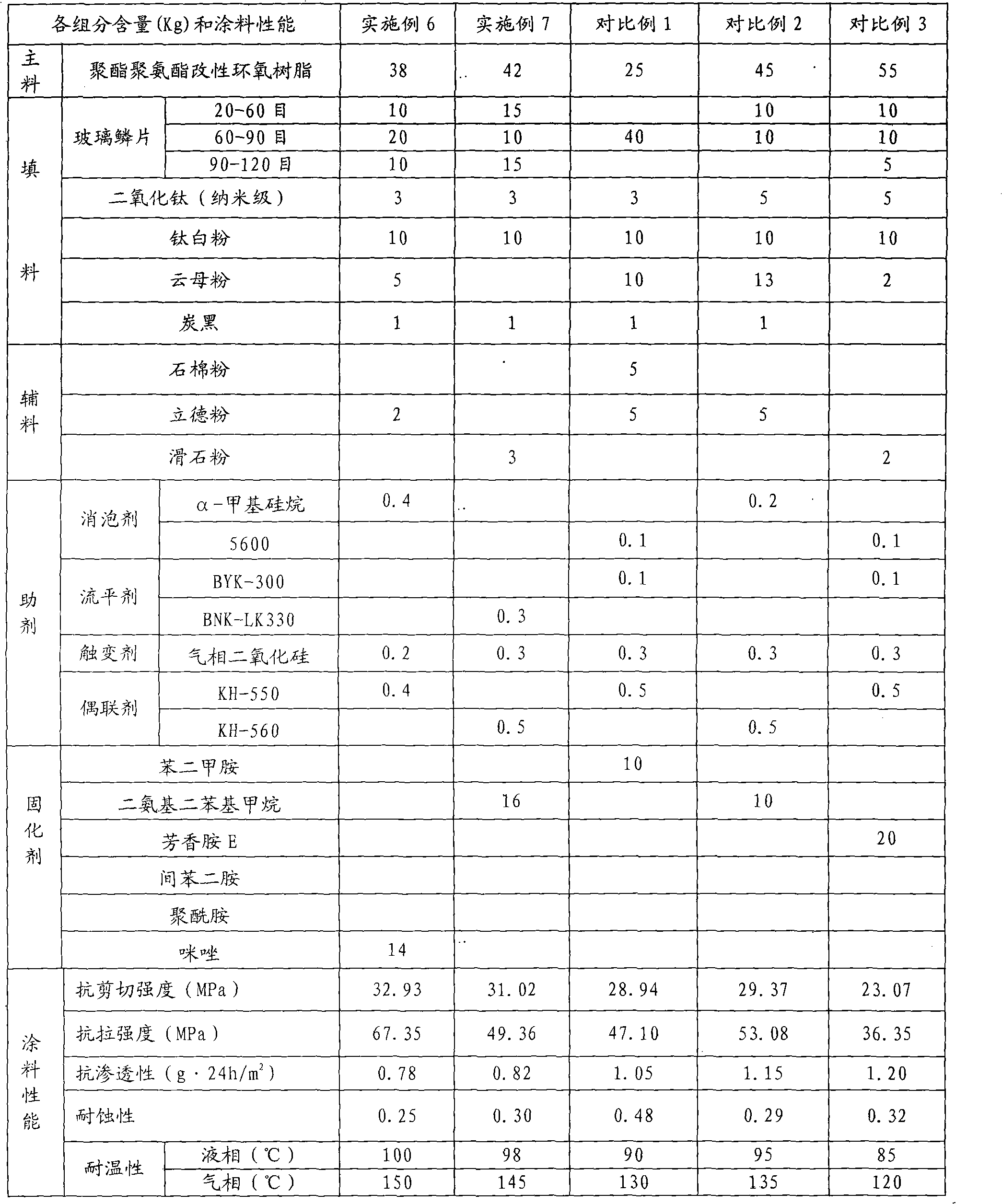

[0042] The polyester urethane modified epoxy resin is added by the weight listed in table 1, i.e. 15kg, and fillers, auxiliary materials, and auxiliary agents other than glass flakes by the weight listed in table 1 and stirred for 15 minutes, and then The mixing material is ground to 20-30μm by a three-roller mill to obtain the grinding material, and then the grinding material, 15kg polyester polyurethane modified epoxy resin and the weight listed in the glass flakes in Table 1 are added to the high-speed mixer, stirred for 30 minutes and mixed Evenly, get the required A component of the new polymer anti-corrosion coating material, put the A component into the iron bucket for standby, when construction is used, first clean and derust the surface of the equipment that needs to be coated with the anti-corrosion coating material, Then take diaminodiphenylmethane according to the weight listed in the curing agent in Table 1 as component B and component A and stir and mix evenly to ...

Embodiment 3

[0044] The method of Example 1 was repeated at the weights of the various components specified in Table 1, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com