Martensitic stainless steel for oil casing and manufacturing method thereof

A martensitic stainless steel and manufacturing method technology, applied in manufacturing tools, heat treatment equipment, heat treatment furnaces, etc., can solve the problem of high cost and achieve the effects of high production efficiency, good hardenability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

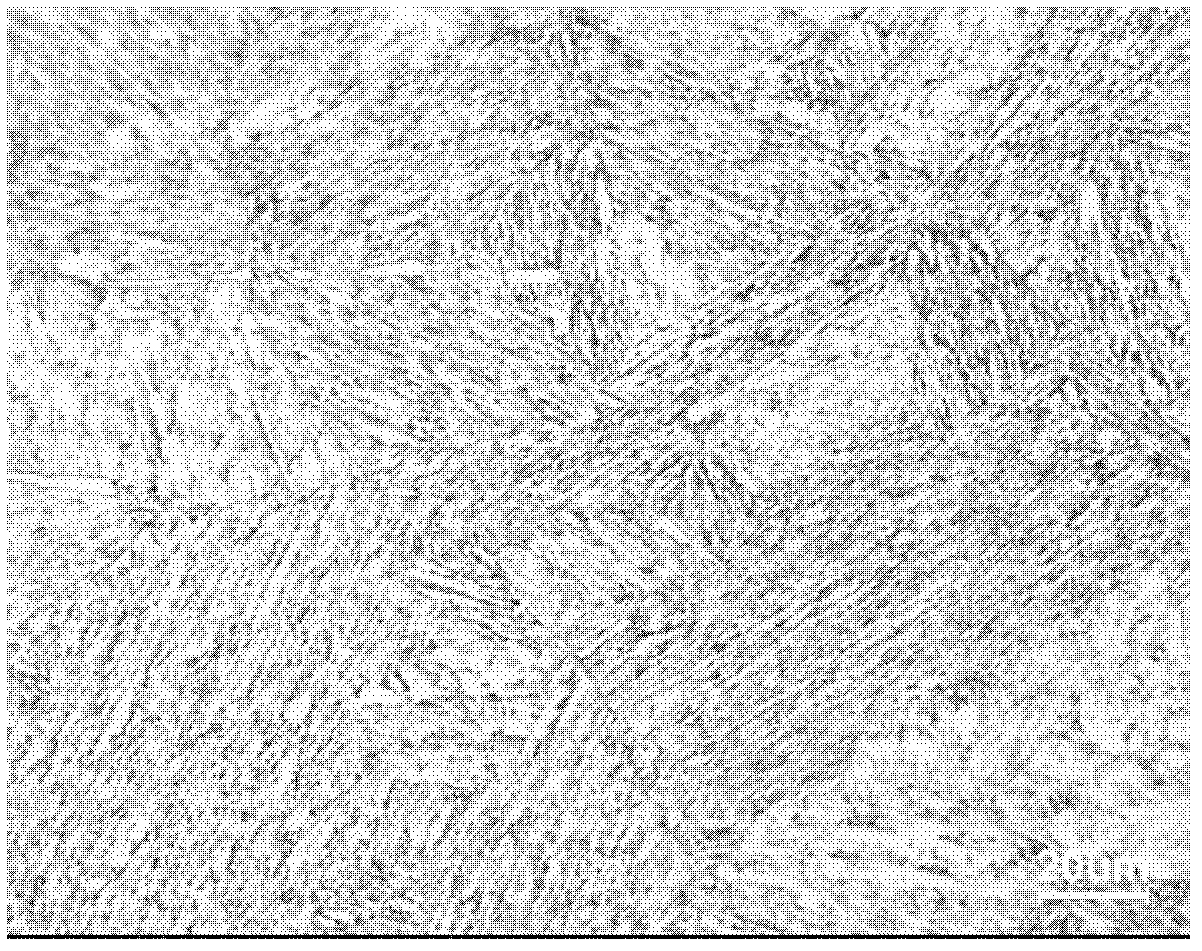

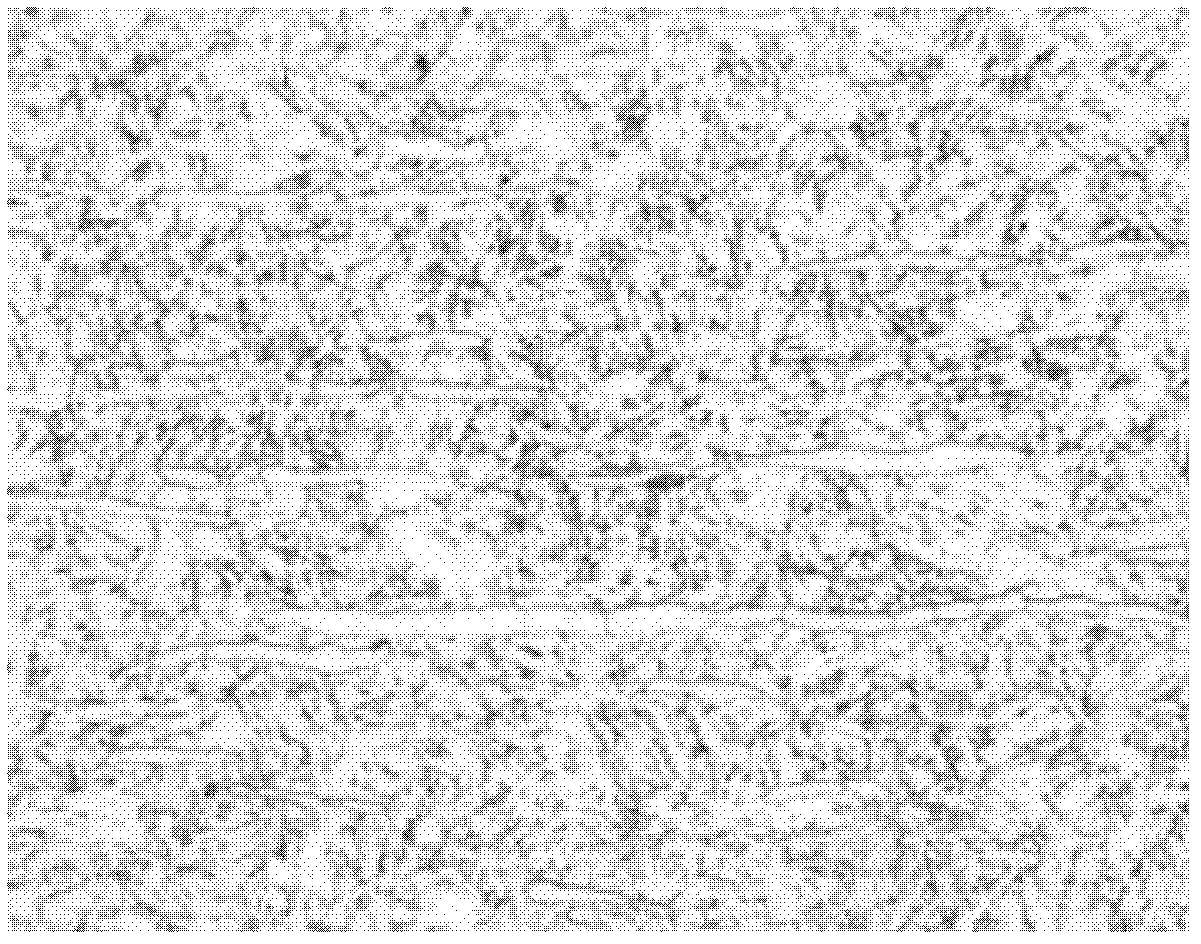

Image

Examples

Embodiment

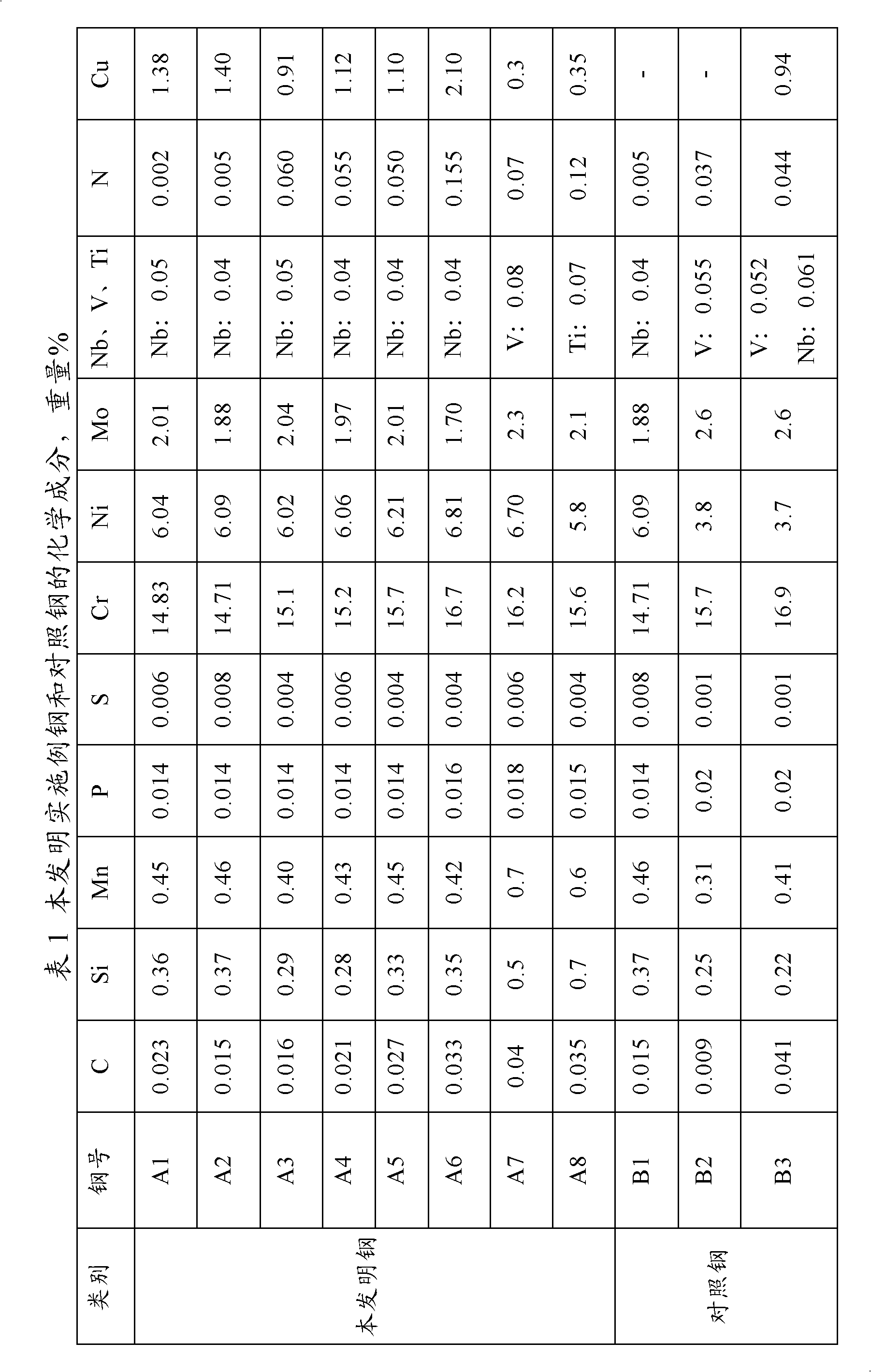

[0030] Table 1 shows the chemical composition of the steels A1-A8 of the examples of the present invention and the steels B1-B3 of the comparison. Among them, B1 steel does not add N, Cu and other elements, and the matrix contains more than 10% high-temperature ferrite.

[0031]The processing and manufacturing methods of the steel in the embodiment of the present invention and the reference steel are as follows: 1) smelting in a vacuum furnace, protective pouring into a round ingot, and forming by hot rolling after casting the ingot. 2) Carry out modulated heat treatment, the heat treatment quenching temperature is 950-1100°C, keep warm for 45 minutes, then take out the furnace and air cool to around room temperature; tempering temperature is 550-650°C, keep warm for 60 minutes, and air cool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com