Bridge compound pier stud structure based on orientation ECC and construction process

A composite pier and column structure technology, which is applied to bridges, bridge construction, bridge parts, etc., can solve problems such as poor compaction of pouring, achieve the effects of improving seismic energy absorption capacity, reducing maintenance costs, and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

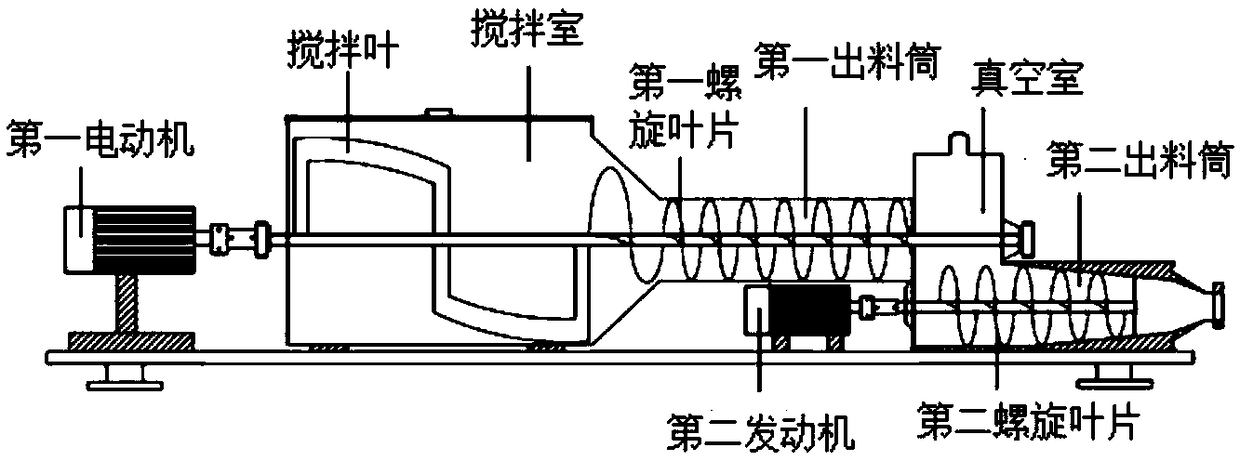

[0074] The ECC orientation machine used in this embodiment, such as figure 1 As shown, it is composed of a first propulsion part and a second propulsion part; the first propulsion part includes a first motor, a stirring chamber, a first discharge cylinder and a vacuum chamber, and the stirring chamber, the first discharge cylinder and the vacuum chamber are sequentially Connected, the first motor is connected to the first transmission shaft, the first transmission shaft runs through the mixing chamber, the first discharge cylinder and the vacuum chamber in sequence, the part of the first transmission shaft located in the mixing chamber is provided with stirring blades, and the first transmission shaft is located in the first The part of the discharge cylinder is provided with a first helical blade; the first propulsion part includes a second motor and a second discharge cylinder, the second motor is connected to the second rotating shaft, and the second rotating shaft passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com