Steel fibre with multi-anchor fixed point

A technology of steel fibers and anchor points, applied in the field of steel fibers, can solve the problems of increasing the flexural resistance and cracking performance of concrete, small gripping force and anchoring force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

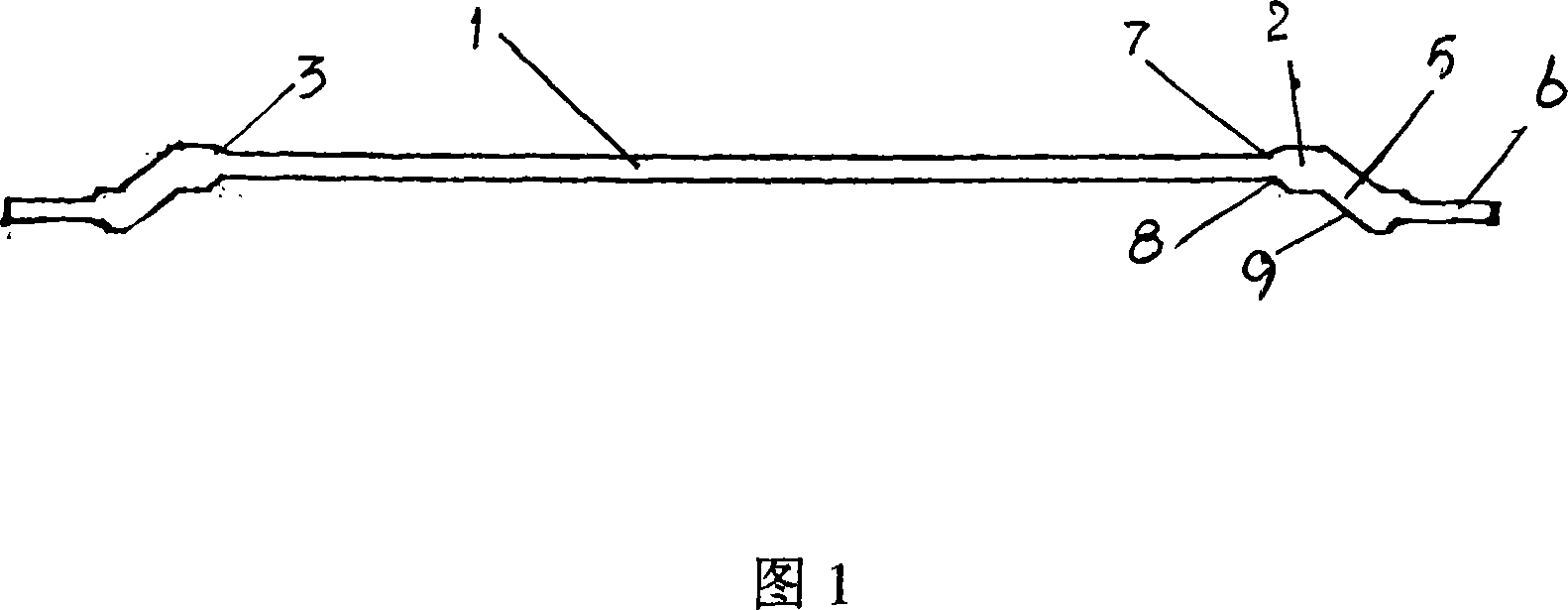

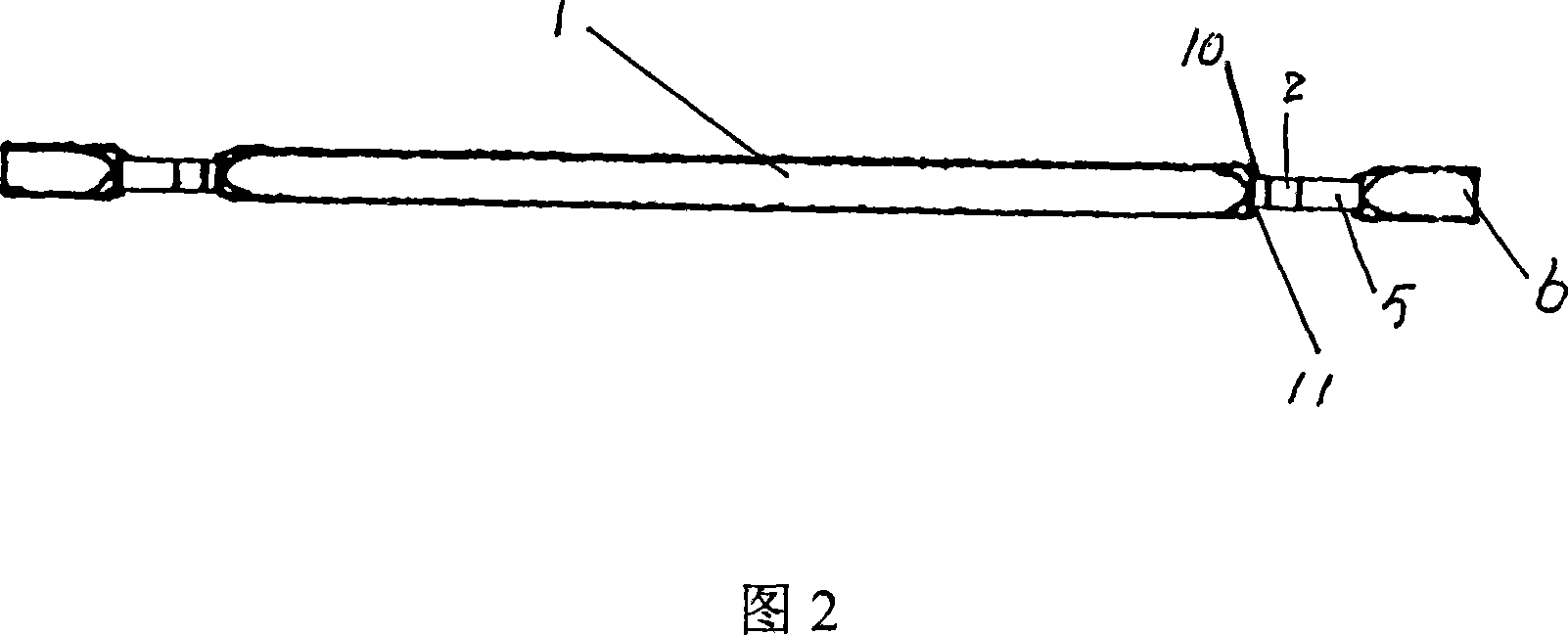

[0009] As shown in Figure 1, the cross-section of the connecting section 1 of the steel fiber is flat and straight, and is formed by cold rolling with a circular section. Section 2, between the first anchoring section 2 and the middle connecting section 1 is a vertical plane connection or an inclined plane connection, and this embodiment adopts an inclined plane connection 3 for transition. The protruding portion of the first anchoring segment 2 is in a vertical plane. The cross section of the first anchoring section 2 is circular. There is a second anchoring section 5 connected to the first anchoring section 2, and there is an obtuse angle between the second anchoring section 5 and the axis of the first anchoring section 2, and the included angle is 120-150°: the second anchoring section 5 The cross section is circular; the third anchoring section 6 is connected to the second anchoring section 5, and there is an included angle between the third anchoring section 6 and the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com