Nitrile copolymer rubber composition and rubber crosslink

A technology of rubber composition and nitrile copolymer, applied in the field of nitrile copolymer rubber composition, can solve problems such as cracking of core molds, and achieve the effects of good cold resistance, excellent resistance to cracking of core molds, and good ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

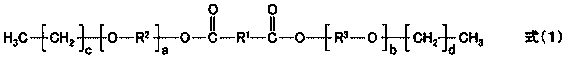

Method used

Image

Examples

preparation example Construction

[0133] The preparation method of the cross-linkable nitrile rubber composition of the present invention is not particularly limited. A cross-linking agent, a cross-linking auxiliary agent, and other compounding agents can be added to the nitrile copolymer rubber composition obtained by the above-mentioned method. Or Banbury mixer and other mixers for mixing.

[0134] It should be noted that the order of mixing at this time is not particularly limited. After the components that are difficult to react or decompose by heat are sufficiently mixed, the components that are easily decomposed by heat can be mixed in a short time at a temperature that does not cause decomposition (crosslinking). Agent, crosslinking accelerator, etc.).

[0135] Mooney viscosity of the crosslinkable nitrile rubber composition of the present invention (hereinafter, sometimes referred to as "compound? Mooney viscosity") (ML 1+4 , 100°C) is preferably 5 to 300, more preferably 10 to 250.

[0136] Rubber cross-l...

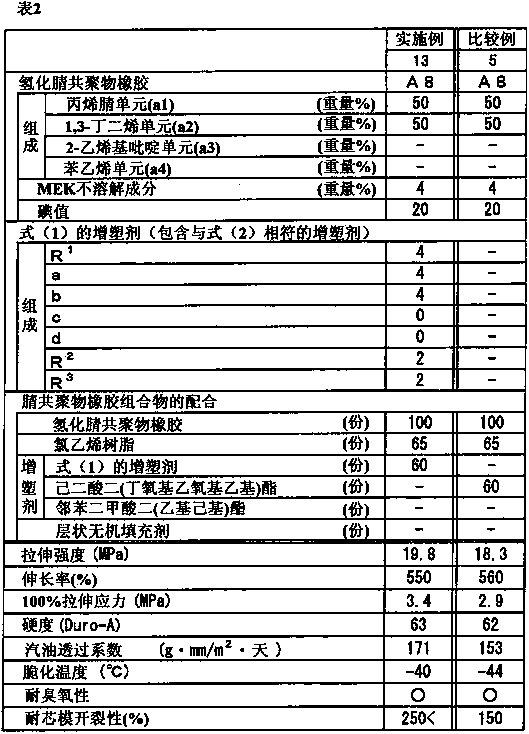

Embodiment

[0148] Hereinafter, examples and comparative examples are given to specifically explain the present invention. Hereinafter, unless otherwise stated, "parts" are based on weight. In addition, the test and evaluation were performed as follows.

[0149] Mooney viscosity

[0150] Mooney viscosity (polymer? Mooney viscosity) of nitrile copolymer rubber (including the case of "hydrogenated nitrile copolymer rubber") (ML 1+4 , 100℃) Measured in accordance with JIS K6300.

[0151] Insoluble components of methyl ethyl ketone (MEK)

[0152] Immerse 1 g of nitrile copolymer rubber (including the case of "hydrogenated nitrile copolymer rubber") in 200 ml of methyl ethyl ketone, leave it at 23°C for 24 hours, and filter with an 80 mesh metal mesh, and evaporate the filtrate to dryness After curing, the obtained residual dry solid content [methyl ethyl ketone soluble content: (y) g] was weighed, and the methyl ethyl ketone insoluble content was calculated by the following formula.

[0153] Inso...

manufacture example 1

[0170] Production Example 1 (Production of latex of nitrile copolymer rubber (A1))

[0171] 240 parts of water, 75.7 parts of acrylonitrile, and 2.5 parts of sodium dodecylbenzene sulfonate (emulsifier) were added to the reaction vessel, and the temperature was adjusted to 5°C. Next, after depressurizing the gas phase and sufficiently degassing, 22 parts of 1,3-butadiene, 0.06 parts of p-terpene hydrogen peroxide as a polymerization initiator, 0.02 parts of sodium ethylenediaminetetraacetate, and ferrous sulfate ( 7 water salt) 0.006 parts, 0.06 parts of sodium formaldehyde sulfoxylate, and 1 part of tert-dodecyl mercaptan as a chain transfer agent to start the first stage reaction of emulsion polymerization. After the start of the reaction, when the polymerization conversion rate relative to the added monomer reached 42% by weight and 60% by weight, 12 parts and 12 parts of 1,3-butadiene were added to the reaction vessel to perform the second stage and The third stage of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com