Modified clay and preparation method thereof

A clay and modification technology, which is applied in the field of modified clay and its preparation, can solve the problems of increasing coke selection yield, long modification period and high silicon extraction rate, and achieves improved heavy oil cracking capacity, high micro-reactive activity, and high cracking capacity. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

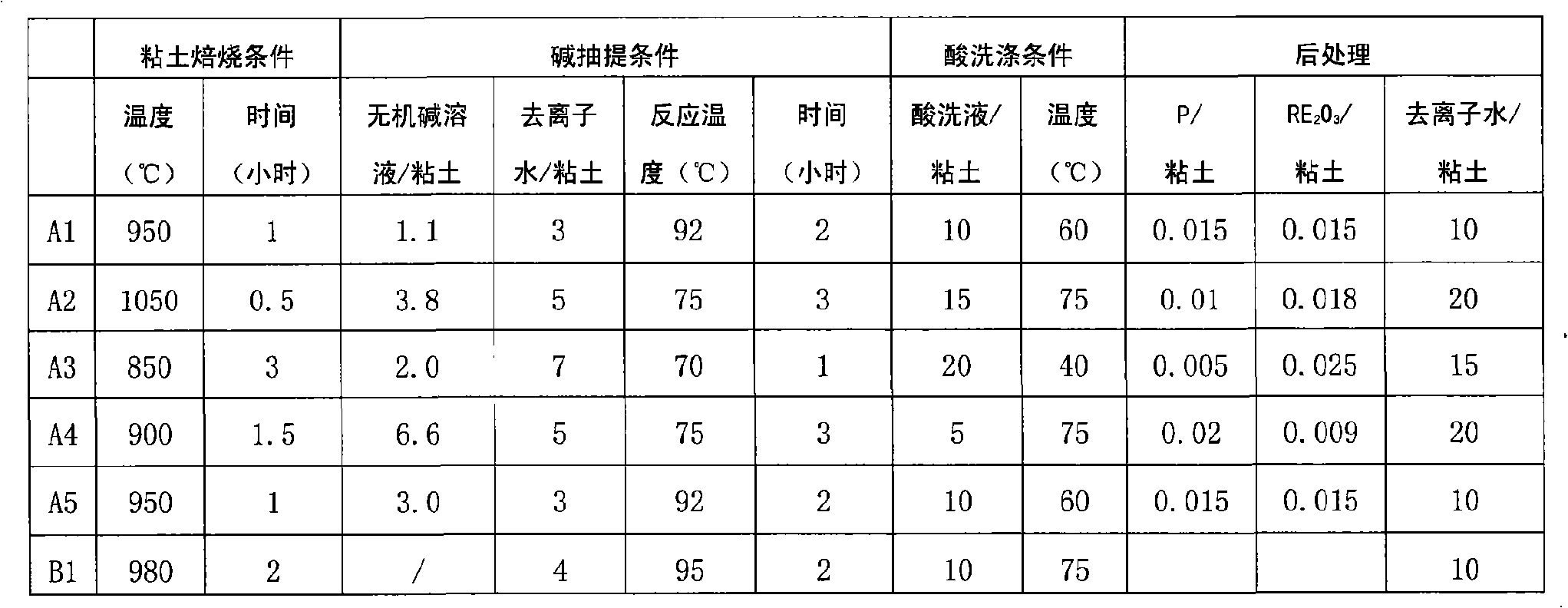

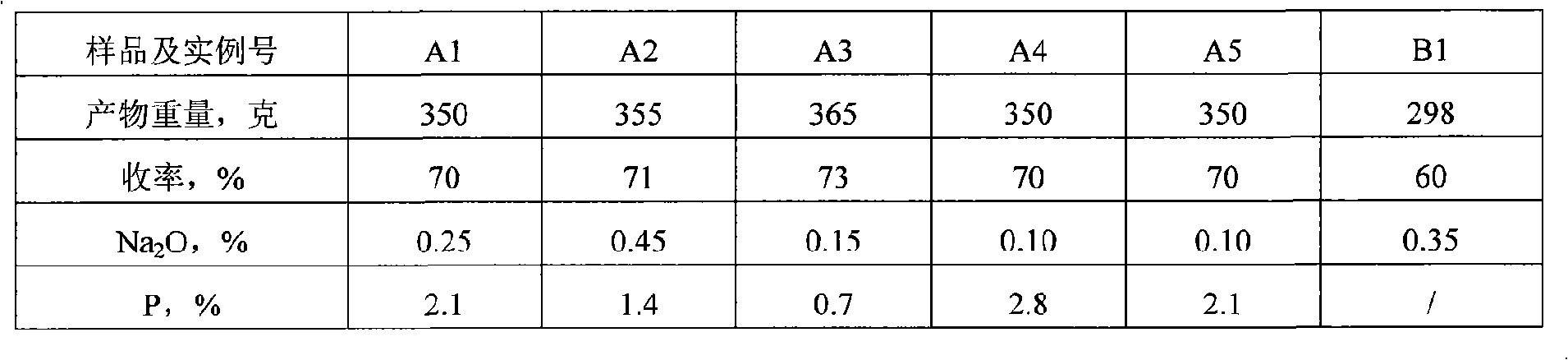

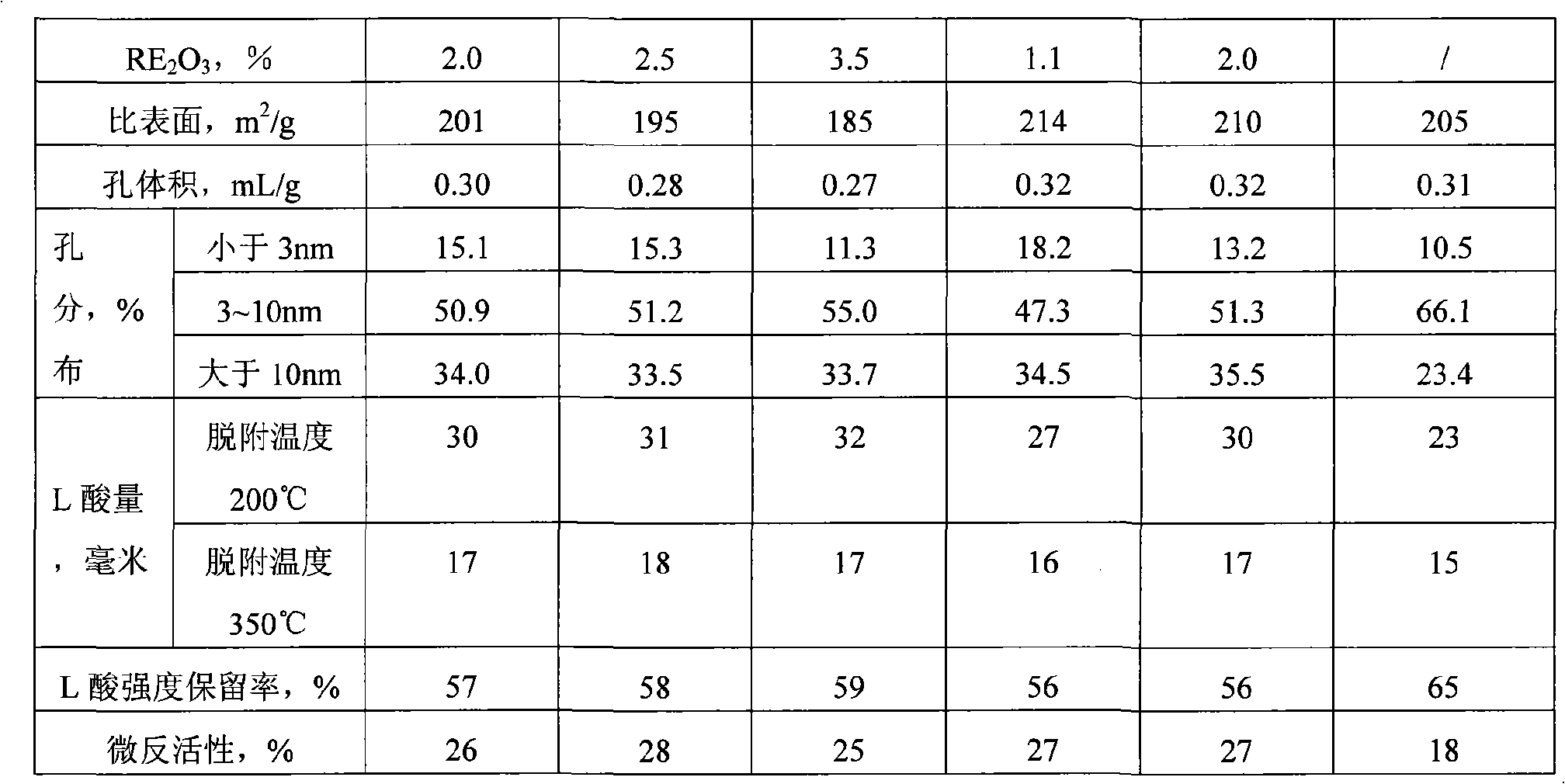

Embodiment 1

[0047] Roast 600 g of kaolin in a muffle furnace at 950 ° C for 1 hour, mix it with 1500 ml of deionized water evenly after cooling, add 630 g of sodium hydroxide solution with 10 moles of hydroxide ions / liter, and heat up to 92 °C under stirring. ℃, stirred and reacted for 2 hours, then filtered, washed with 5000 ml of 75 ℃ dilute sulfuric acid, and then made a slurry with 5000 ml of deionized water, added 38 grams of phosphoric acid, 30 ml of rare earth chloride solution, stirred at 60 ℃ for 0.5 hours, filtered and drying to obtain the modified clay A1 prepared by the present invention.

Embodiment 2

[0049] Roast 600g of halloysite at 1050°C in a muffle furnace for 0.5 hours, mix it with 2500ml of deionized water after cooling, add 1600g of sodium hydroxide solution with 5 moles of hydroxide ions / liter and 1 mole of hydroxide 680 grams of water glass per liter, under stirring, heat up to 75°C, stir and react for 3 hours, then filter, wash with 7500 ml of dilute hydrochloric acid at 75°C, beat with 10,000 ml of deionized water, add 25 grams of ammonium phosphate , 36 ml of rare earth nitrate solution, stirred at 40° C. for 2 hours, filtered, and dried to obtain modified clay A2 prepared by the present invention.

Embodiment 3

[0051] 600g of kaolin was roasted at 850°C for 3 hours in a muffle furnace, mixed evenly with 3500 milliliters of deionized water after cooling, and 800 grams of sodium hydroxide solution of 14 moles of hydroxide ions / liter and 1 mole of hydroxide ions / liter were added. liter of sodium metaaluminate 400g, under stirring, heat up to 120°C, stir and react for 1 hour, then filter, wash with 10000ml of dilute sulfuric acid at 50°C, beat with 7500ml of deionized water, add 9g of phosphorous acid , 50 ml of rare earth chloride solution, stirred at 80° C. for 1 hour, filtered, and dried to obtain modified clay A3 prepared in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com