Silicon-aluminum material, preparation method and applications thereof

A silicon-aluminum material, aluminum source technology, applied in chemical instruments and methods, catalytic cracking, metal/metal oxide/metal hydroxide catalysts, etc. The problems of friendliness, increased preparation cost, etc., to achieve the effect of enhanced pore accessibility, good hydrothermal stability, and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example illustrates the silicon-aluminum material provided by the present invention and its preparation process.

[0030] At room temperature the water glass solution (concentration 80gSiO 2 / L) is placed in a beaker, drip ammonia water (content 17%) under stirring, after continuing to stir for 10 minutes, press Al under vigorous stirring 2 o 3 : SiO 2 = 0.5:1 ratio will Al 2 (SO 4 ) 3 Solution (concentration 90gAl2 o 3 / L) Add and adjust the final pH value of the slurry to 8.5, raise the temperature to 50°C and stir at a constant temperature for 3 hours; filter the resulting solid precipitate according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.8:10 was exchanged at 60° C. for 1 hour, filtered and washed with water to obtain a silicon-aluminum material sample provided by the present invention, which was designated as HS-1.

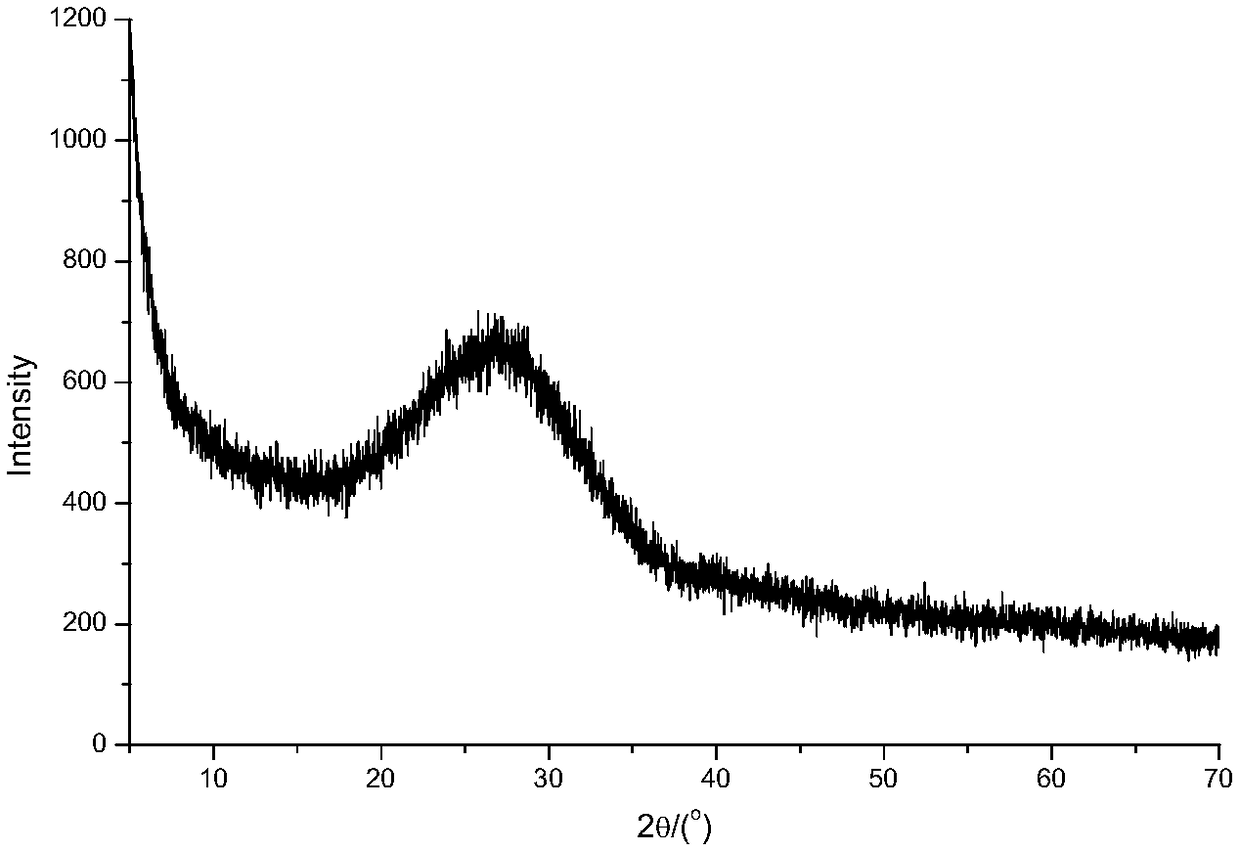

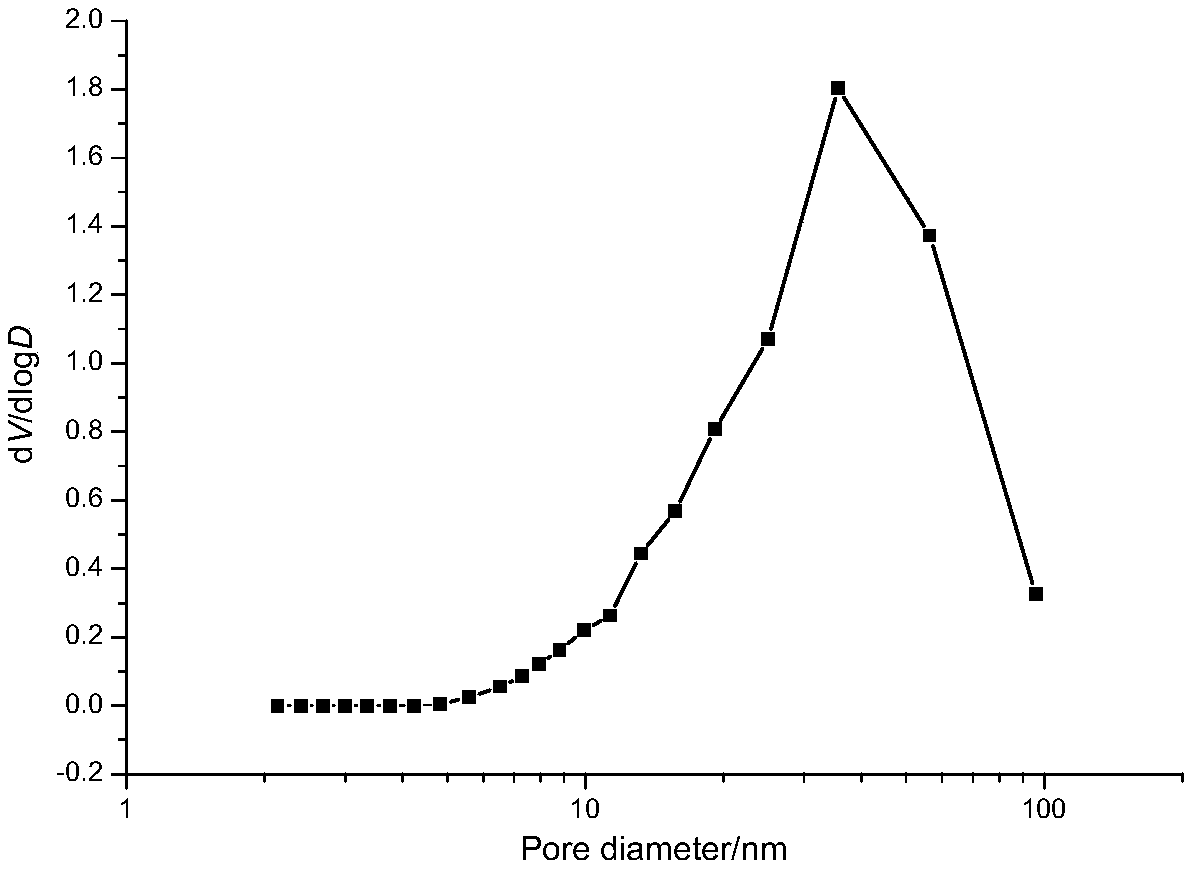

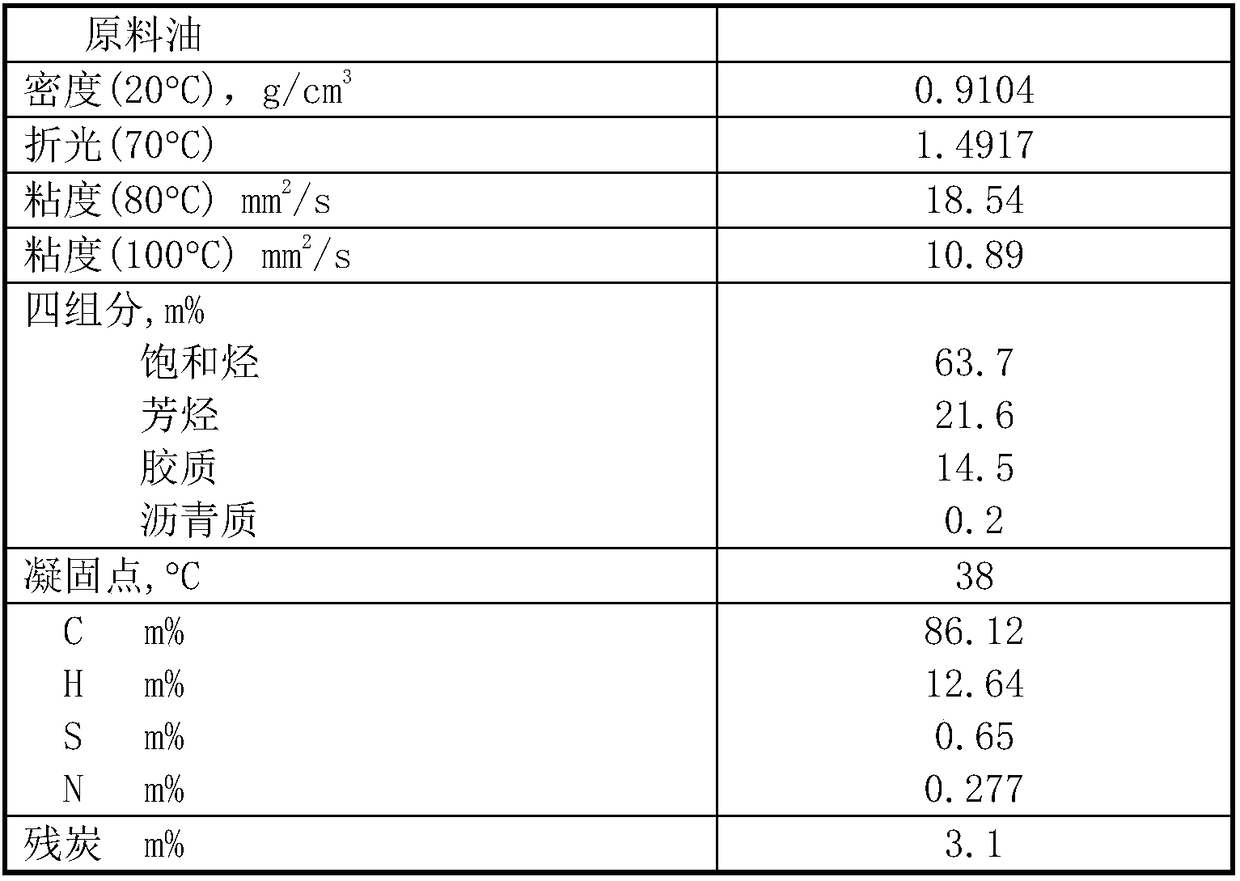

[0031] The X-ray diffraction spectrum of sample HS-1 is shown in figure 1 , figure 1 Among th...

Embodiment 2

[0035] This example illustrates the silicon-aluminum material provided by the present invention and its preparation process.

[0036] The measured water glass solution (concentration 80gSiO 2 / L) placed in a beaker and heated up to 40°C, under stirring, a quantitative concentration of 1M sodium hydroxide solution was added therein, and after stirring for 10 minutes, press Al 2 o 3 : SiO 2 = 0.4:1 ratio will Al 2 (SO 4 ) 3 Solution (concentration 90gAl 2 o 3 / L) Add and adjust the final pH value of the slurry to 10.0, continue to heat up to 60°C and stir at a constant temperature for 1 hour; filter the resulting solid precipitate on a dry basis: ammonium salt: H 2 The weight ratio of O=1:0.8:12 was exchanged at 70°C for 0.5 hours, filtered and washed with water, and the ammonium exchange was repeated once. After filtering, the silicon-aluminum material sample provided by the present invention was obtained, which was designated as HS-2.

[0037] The X-ray diffraction spe...

Embodiment 3

[0041] This example illustrates the silicon-aluminum material provided by the present invention and its preparation process.

[0042] Put the measured amount of tetraethoxy silicon (TEOS) in the beaker and add a small amount of deionized water, stir and heat up to 50°C, then slowly add a quantitative concentration of 1M sodium hydroxide solution into it, and continue stirring for 30 minutes , by Al under vigorous stirring 2 o 3 : SiO 2 =0.6:1 ratio will Al(NO 3 ) 3 Solution (concentration 60gAl 2 o 3 / L) to add and adjust the final pH value of the slurry to 10.5, continue to heat up to 80°C and stir at a constant temperature for 2 hours; after filtering, the resulting solid precipitate is calculated on a dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.4:10 was exchanged at 50° C. for 1 hour, filtered and washed with water to obtain a silicon-aluminum material sample provided by the present invention, which was designated as HS-3.

[0043] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com