Flexible conductive film

A flexible conductive and flexible technology, applied in the optical field, can solve the problems of low adhesion, easy falling off of the nano-silver wire layer, cumbersome process, etc., and achieve the effect of improving the performance of blocking water vapor, not easy to break, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

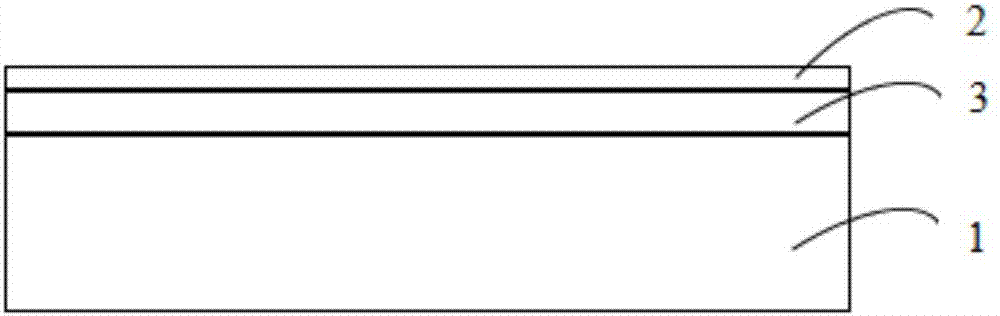

[0043] See figure 1 , a flexible conductive film, including a flexible base material layer 1, a flexible conductive layer 2 and a flexible water vapor barrier layer 3, the flexible water vapor barrier layer 3 is arranged on one side surface of the flexible base material layer 1, and the flexible conductive layer 2 is arranged on the flexible water vapor barrier layer On the surface of layer 3 on the side away from flexible substrate layer 1, the specific preparation steps are as follows:

[0044]S1. Provide a flexible substrate layer 1 as a substrate. The flexible substrate layer 1 can be prepared by a screw extruder, which specifically includes melting the optical film particles required to form the substrate layer, and then extruding with a screw. The machine uniformly extrudes the base material layer material in the molten state to form a film-like flexible base material layer 1, and longitudinally or transversely stretches the formed flexible base material layer 1, so that...

Embodiment 2

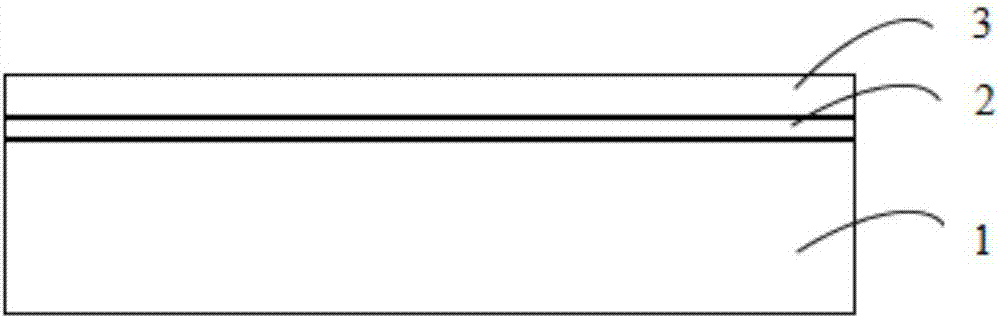

[0050] See figure 2 , a flexible conductive film, including a flexible substrate layer 1, a flexible conductive layer 2 and a flexible water vapor barrier layer 3, the flexible conductive layer 2 is arranged on one side surface of the flexible substrate layer 1, and the flexible water vapor barrier layer 3 is arranged on the flexible conductive layer 2 on the surface of the side away from the flexible substrate layer 1, the specific preparation steps are as follows:

[0051] S1. Provide a flexible substrate layer 1 as a substrate, and the preparation of the flexible substrate layer 1 is the same as that described in Embodiment 1;

[0052] S2. Prepare a flexible conductive layer 2 on the surface of the flexible substrate layer 1. Preferably, the coating solution mixed with silver nanowires is evenly coated on one side surface of the flexible substrate layer 1 to form a flexible conductive layer 2. The coating thickness of the flexible conductive layer is controlled between 5-...

Embodiment 3

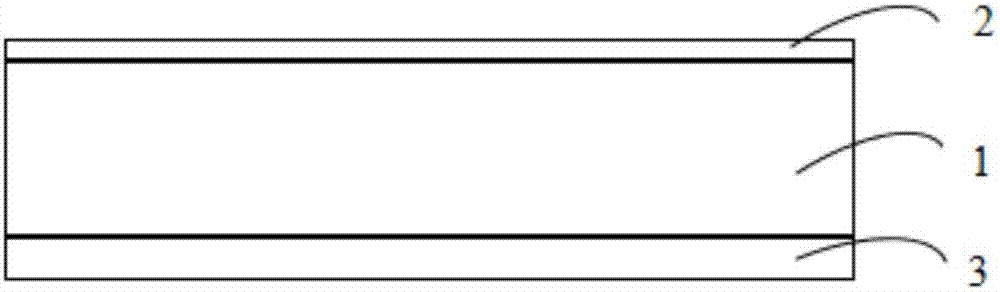

[0056] See image 3 , a flexible conductive film, including a flexible substrate layer 1, a flexible conductive layer 2 and a flexible water vapor barrier layer 3. The difference from Embodiment 1 and Embodiment 2 is that at this time, the flexible substrate layer 1 is located in the middle, and the flexible conductive layer 2 and the flexible water vapor barrier layer 3 are located on both sides of the flexible substrate layer 1 respectively, so that the flexible substrate layer 1 can be better protected from oxidation, corrosion, and the influence of the external environment. The specific preparation steps as follows:

[0057] S1. Provide a flexible substrate layer 1 as a substrate, and the preparation of the flexible substrate layer 1 is the same as that described in Embodiment 1 and Embodiment 2;

[0058] S2. Prepare the flexible conductive layer 2 and the flexible water vapor barrier layer 3 on both sides of the flexible substrate layer 1 respectively. The preparation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com