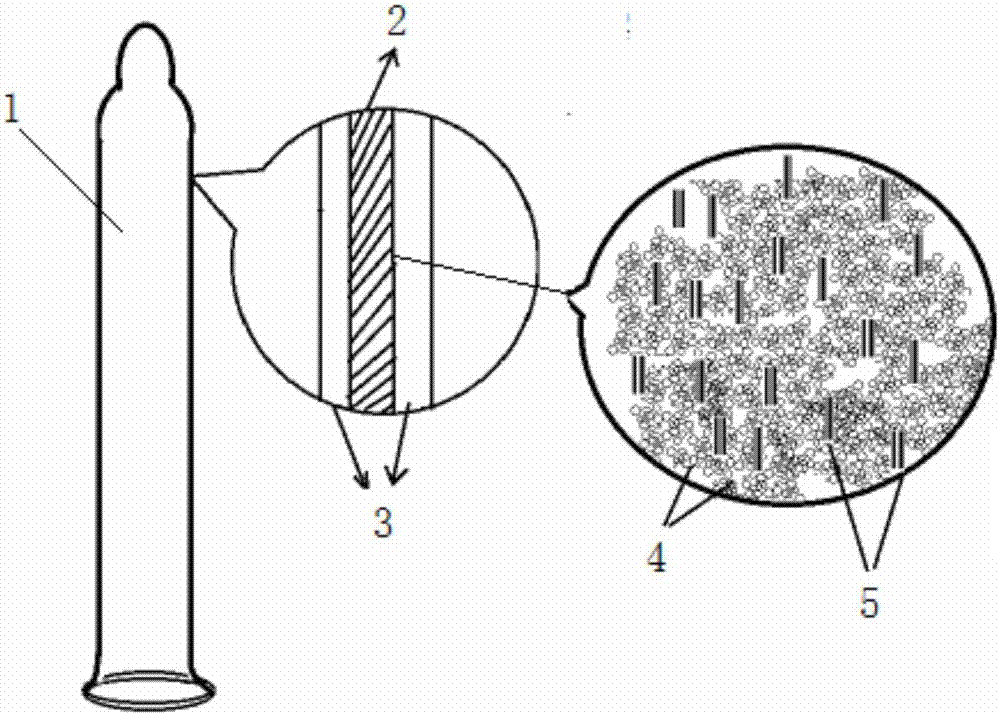

Method of producing sandwich-structure sensitization-free isolating condom from graphene laminating nano boron nitride compounded latex

A nano-boron nitride and composite latex technology, applied in male contraceptives and other directions, can solve the problems of poor weather resistance and deepening color, and achieve the effect of inertness, non-toxicity, scientific principle, and barrier penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

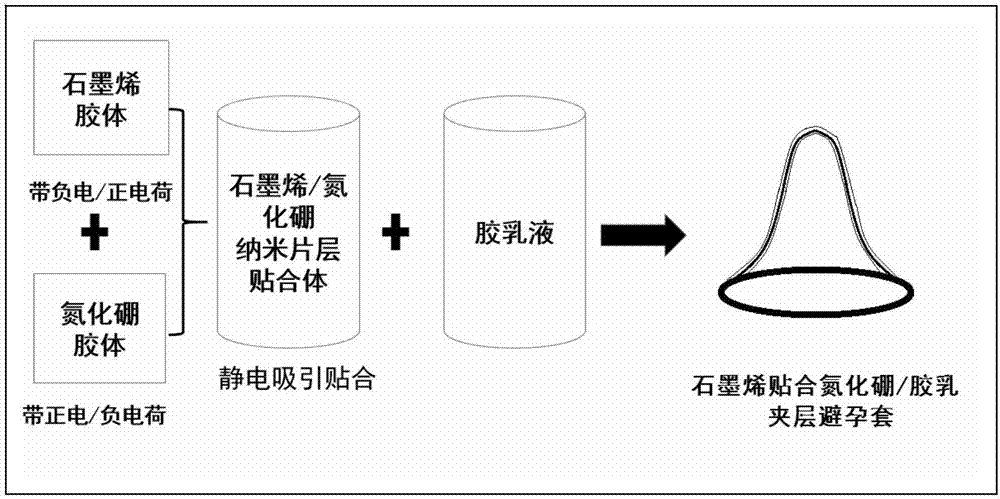

[0032] In this embodiment, the method of preparing interlayer non-sensitive isolation condom by laminating graphene with nano-boron nitride composite latex is as follows:

[0033] Preparation of graphene / hexagonal nanosheet boron nitride bonded body solution: 1kg of graphene oxide aqueous solution with a concentration of 2wt‰ is negatively charged after being charged by an electric field. 1 kg of an aqueous solution containing 0.1wt‰ hexagonal boron nitride nanosheet material was modified with 0.1wt‰ polyvinylpyrrolidone. Then the two are mixed and stirred ultrasonically to make them dispersed evenly. Adding 10Kg concentration then is the natural rubber latex of 60wt% in the clean mixing bucket, under agitation condition, add gradually the graphene / hexagonal nanosheet boron nitride bonding body solution of 2.1wt‰ that the 2Kg concentration that prepares in front, add After finishing, add 0.1wt‰ dispersion stabilizer Pingpingjia O (alkyl polyoxyethylene ether) in an appropriat...

Embodiment 2

[0040] In this embodiment, the method of preparing interlayer non-sensitive isolation condom by laminating graphene with nano-boron nitride composite latex is as follows:

[0041] Preparation of graphene / hexagonal nanosheet boron nitride bonded body solution: 1kg of graphene oxide with a concentration of 1wt‰ and an aqueous solution of aminated graphene with a concentration of 1wt‰ were negatively charged after being charged by electrodialysis. 1 kg of aqueous solution containing 0.1wt‰ hexagonal boron nitride nanosheet material was modified with 0.1wt‰ sodium dodecylsulfonate. Then the two are mixed and stirred ultrasonically to make them dispersed evenly. Adding 10Kg concentration then is the natural rubber latex of 60wt% in the clean mixing bucket, under agitation condition, add gradually the graphene / hexagonal nanosheet boron nitride bonding body solution of 2.1wt‰ that the 2Kg concentration that prepares in front, add After finishing, 0.1wt‰ dispersion stabilizer polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com