Self-corrosion potential response type self-repairing anti-corrosion coating, preparation method and application

A technology of self-corrosion potential and anti-corrosion coating, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., to achieve the effects of high sensitivity, not easy to fall off, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of epoxy-silane composite coating substrate

[0040] Dissolve 3g of 3-aminopropyltriethoxysilane in 12.7mL of ethanol, dissolve 34.9g of epichlorohydrin-propanediol copolymerized epoxy resin in 40 mL of acetone, mix the two solutions evenly and add 3.8 g of triethylenetetramine were stirred.

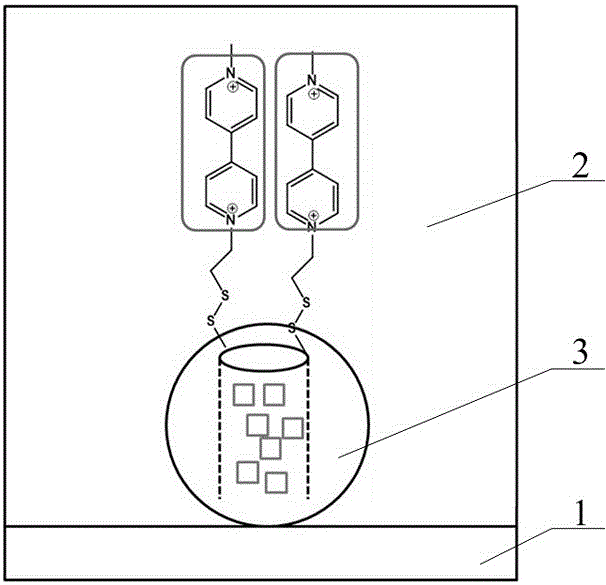

[0041] 2. Preparation of mesoporous silica nanocontainers

[0042] Disperse 0.5 g of cetyltrimethylammonium bromide (CTAB) in 240 mL of deionized water, then add 1.75 mL of 2 mol / L sodium hydroxide solution, and keep warm at 80°C for half an hour. 2.5 mL tetraethyl orthosilicate (TEOS) was added dropwise to the reaction system at a rotational speed of 700 rpm, and reacted for 2 h. After the reaction was completed, it was filtered while it was hot, the product was fully washed with hot water, and vacuum-dried at 80°C.

[0043] Weigh 200 mg of the dried solid product, grind it thoroughly, add a mixed solution of 50 mL of methanol and 3 mL of concentrated hydrochloric...

Embodiment 2

[0051] 1. Preparation of epoxy-silane composite coating substrate

[0052] Dissolve 1.5 g of tetraethyl orthosilicate in 6.3 mL of ethanol solution, dissolve 17.5 g of epichlorohydrin-propanediol copolymerized epoxy resin in 20 mL of acetone, mix the two solutions with ethyl ester, and then add Add 1.9 g of diethyltriamine and stir well.

[0053] 2. Preparation of mesoporous silica nanocontainers

[0054] Disperse 0.5 g of cetyltrimethylammonium bromide (CTAB) in 240 mL of deionized water, then add 1.75 mL of 2 mol / L sodium hydroxide solution, and keep warm at 80°C for half an hour. 2.5 mL tetraethyl orthosilicate (TEOS) was added dropwise to the reaction system at a rotational speed of 700 rpm, and reacted for 2 hours. After the reaction was completed, it was filtered while it was hot, the product was fully washed with hot water, and vacuum-dried at 80°C.

[0055] Weigh 200 mg of the dried solid product, grind it thoroughly, add a mixed solution of 50 mL of methanol and 3 ...

Embodiment 3

[0067] 1. Preparation of epoxy-silane composite coating substrate

[0068] Dissolve 0.75 g of tetraethyl orthosilicate and 0.75 g of 3-glycidyl ether propyl trimethoxysilane in 6.3 mL of ethanol solution, and dissolve 17.5 g of epichlorohydrin-propanediol copolymerized epoxy resin in 20 mL of acetone In, the ethyl esters of these two solutions were mixed, and then 1.9 g of diethyltriamine was added thereto, and stirred evenly.

[0069] 2. Preparation of mesoporous silica nanocontainers

[0070] Disperse 0.5 g of cetyltrimethylammonium bromide (CTAB) in 240 mL of deionized water, then add 1.75 mL of 2 mol / L sodium hydroxide solution, and keep warm at 80°C for half an hour. 2.5 mL tetraethyl orthosilicate (TEOS) was added dropwise to the reaction system at a rotational speed of 700 rpm, and reacted for 2 h. After the reaction was completed, it was filtered while it was hot, the product was fully washed with hot water, and vacuum-dried at 80°C.

[0071]Weigh 200mg of the dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com