Method for preparing single-wall carbon nanotube fiber by using mixed gaseous carbon source

A technology of single-walled carbon nanotubes and gaseous carbon sources, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of quality, purity, and output at the same time, and achieve good industrial Application prospects, high strength, large output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

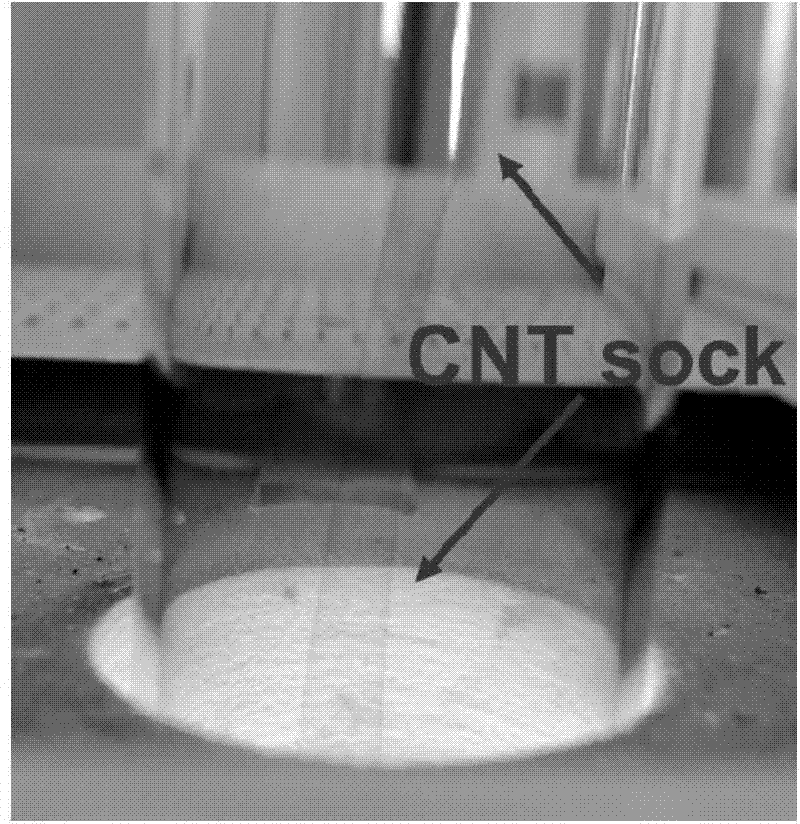

[0039] The flaky mixture containing ferrocene and sulfur powder (the weight ratio of ferrocene and sulfur powder is 100:1, after mixing evenly, press it into a tablet under 10MPa pressure) is placed in the low temperature zone in the tube, at 100sccm (ml / min ) under an argon protective atmosphere, the furnace temperature was raised to 1100°C at a rate of 20°C / min. After the temperature stabilized, the flow rate of argon was adjusted to 200 sccm, and 5 sccm methane, 0.2 sccm ethylene, and 200 sccm hydrogen were introduced simultaneously. When the gas flow is stable, the catalyst precursor is heated to 90°C to sublimate it. At this time, it can be seen that continuous cylindrical carbon nanotube macroscopic bodies ( figure 1 , CNT sock) flows out of the high temperature zone with the carrier gas, and is pre-set mechanical traction and collection at the tail end to form single-walled carbon nanotube fibers.

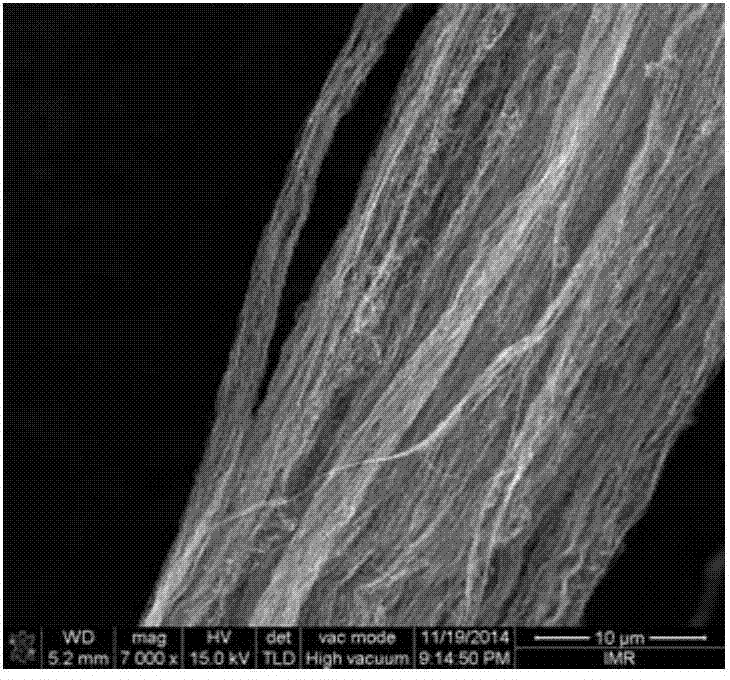

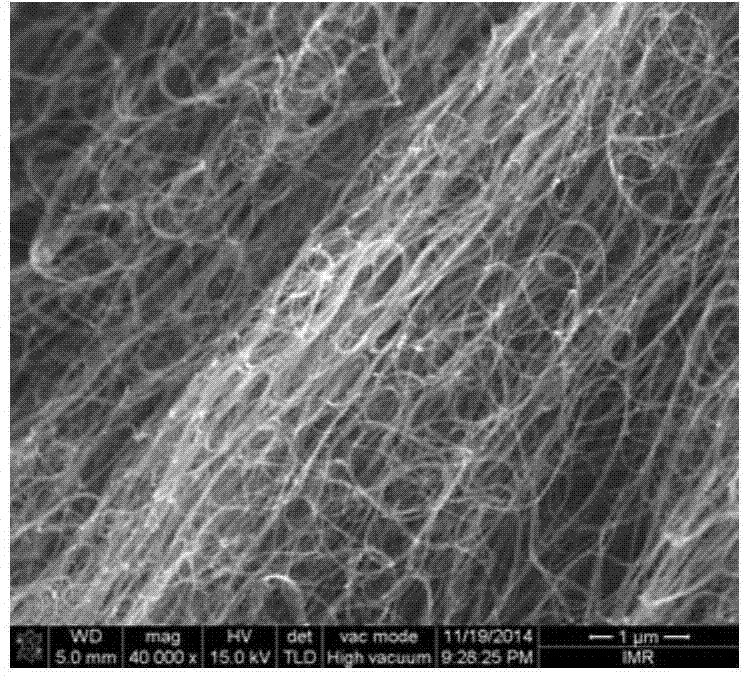

[0040] The above samples (referred to as 1#) were characterized by sc...

Embodiment 2

[0042] The flaky mixture containing ferrocene and sulfur powder (the weight ratio of ferrocene and sulfur powder is 100:1, after mixing evenly, press it into a tablet under 10MPa pressure) is placed in the low temperature zone in the tube, at 100sccm (ml / min ) under an argon protective atmosphere, the furnace temperature was raised to 1000°C at a rate of 20°C / min. After the temperature stabilized, the flow rate of argon was adjusted to 100 sccm, and 1 sccm methane, 0.2 sccm acetylene, and 100 sccm hydrogen were introduced simultaneously. When the gas flow is stable, the catalyst precursor is heated to 60°C to sublimate it. At this time, it can be seen that the continuous cylindrical carbon nanotube macroscopic body formed in the reactor flows out of the high temperature zone with the carrier gas, and is mechanically drawn and collected at the tail end to form single-walled carbon nanotube fibers.

[0043] The above samples (marked as 2#) were characterized by scanning electro...

Embodiment 3

[0045] The flaky mixture containing ferrocene and sulfur powder (the weight ratio of ferrocene and sulfur powder is 100:1, after mixing evenly, press it into a tablet under 10MPa pressure) is placed in the low temperature zone in the tube, at 100sccm (ml / min ) under an argon protective atmosphere, the furnace temperature was raised to 1000°C at a rate of 20°C / min. After the temperature was stabilized, the flow rate of argon was adjusted to 400 sccm, and 10 sccm methane, 2 sccm propylene, and 400 sccm hydrogen were fed simultaneously. When the gas flow is stable, the catalyst precursor is heated to 150°C to sublimate it. At this time, it can be seen that the continuous cylindrical carbon nanotube macroscopic body formed in the reactor flows out of the high temperature zone with the carrier gas, and is mechanically drawn and collected at the tail end to form single-walled carbon nanotube fibers.

[0046] The above samples were characterized by scanning electron microscope, tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com