Preparation method of doped graphene and application of doped graphene

A technology of graphene and doping elements, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low performance index of doped graphene, complex process conditions, unsuitable for industrialization, etc. The effect of large-scale industrial production, few structural defects, and large market potential value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

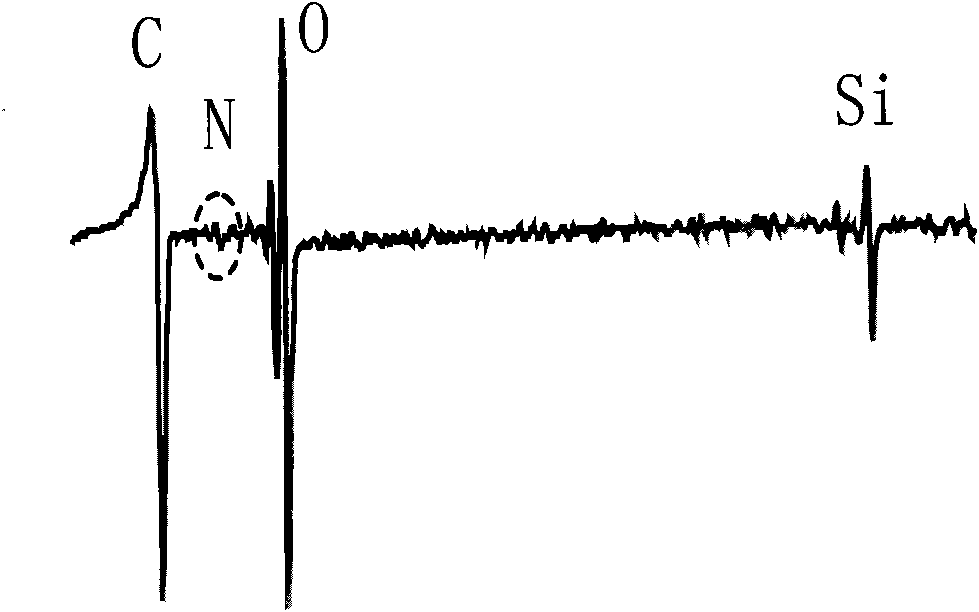

[0045] Embodiment 1 prepares nitrogen-doped graphene

[0046] 1) Defects:

[0047] ion implantation method

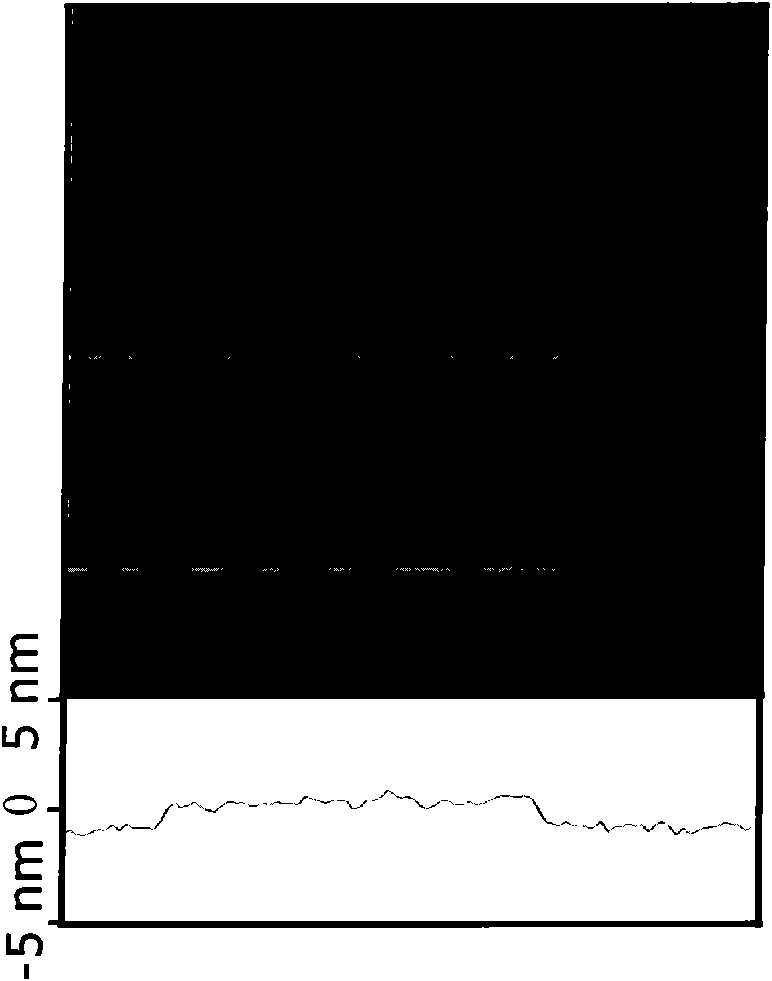

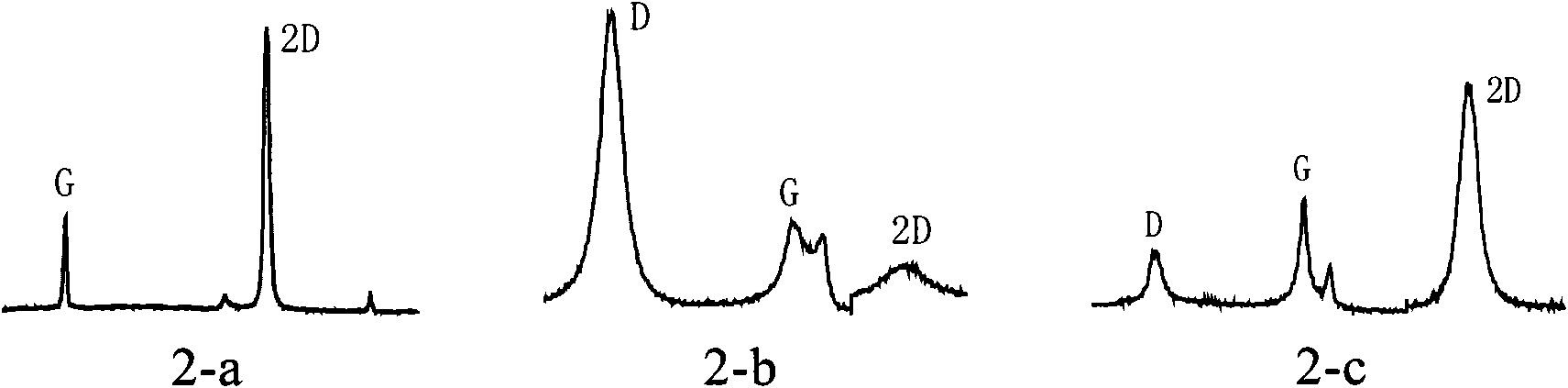

[0048] Step 1: Graphene prepared by mechanical exfoliation (flaky graphite purchased by alfa aesar), chemical vapor deposition or SiC epitaxy (references: [1] Controllable N-doping ofgraphene.DOI: 10.1021 / nl103079j; [2] ]Synthesis of N-Doped Graphene by Chemical Vapor Deposition and Its Electrical Properties. Nano Lett., Vol.9, No.5, 2009; [3] Raman spectrum of epitaxial graphene on SiC (0001), Doi: 10.1063 / 1.2929746) Enter the vacuum chamber of the ion implanter (model: LC-16, production / development unit: the 48th Research Institute of China Electronics Technology Group). Then vacuum, the vacuum degree reaches 10 -4 MPa or higher. figure 1 is the AFM image of graphene prepared by mechanical exfoliation; the Raman spectrum of graphene before ion implantation is shown as figure 2 -a shown.

[0049] Step 2: Setting parameters: Ion type: N + 、Ar + One of them or...

Embodiment 2

[0053] Embodiment 2 prepares boron doped graphene

[0054] 1) Defects:

[0055] plasma method

[0056] Step 1: Graphene prepared by mechanical exfoliation (flaky graphite purchased by alfa aesar), chemical vapor deposition or SiC epitaxy (references: [1] Controllable N-doping ofgraphene.DOI: 10.1021 / nl103079j; [2] ]Synthesis of N-Doped Graphene by Chemical Vapor Deposition and Its Electrical Properties. Nano Lett., Vol.9, No.5, 2009; [3] Raman spectrum of epitaxial graphene on SiC (0001), Doi: 10.1063 / 1.2929746) Into the vacuum chamber of the plasma machine (PS 300SA plasma system, Pfatetop, Germany) or plasma reactive etching equipment (JPCD-300, Beijing Techno Technology Co., Ltd.). Vacuum to 10 -4 MPa.

[0057] Step 2: Set parameters: one or any combination of oxygen, ammonia plasma, etc.;

[0058] Ion energy, 200eV ~ 400KeV; dose: 10 7 ~10 18 piece / cm -2

[0059] 2) Annealing:

[0060] Step 3: Put the defective graphene after plasma treatment in the annealing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com