Lead-free high-dielectric-constant microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and high dielectric constant technology, applied in the field of functional ceramic materials, can solve the problems of polluting the environment and high cost, and achieve the effects of high dielectric constant, reducing dielectric loss, and reducing the number of free electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

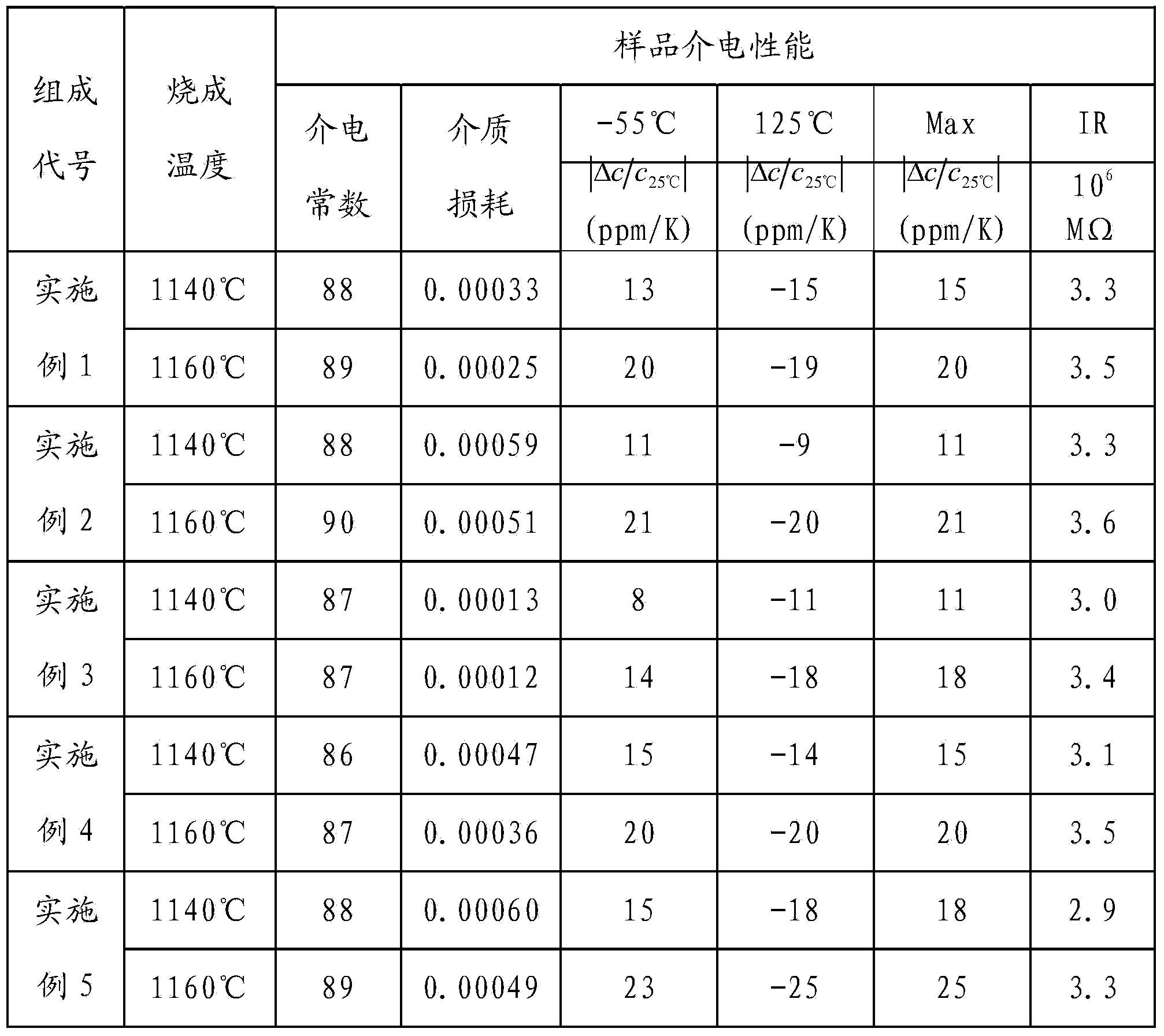

Examples

Embodiment 1

[0039] (1) Weigh 21.85g BaCO respectively 3 , 37.26g Nd 2 o 3 and 40.89g TiO 2 , mixed ball milling, passing through a 40-mesh standard sieve, passing through a 40-mesh standard sieve, and calcining at 1160 ° C for 4 hours to synthesize a barium-neodymium-titanium compound;

[0040] (2) Accurately weigh 85.37gBi 2 o 3 and 14.63TiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 800°C for 2 hours to synthesize Bi 2 TiO 5 compound;

[0041] (3) Accurately weigh 55.62g CaCO 3 and 44.38TiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 1270°C for 2 hours to synthesize CaTiO 3 compound;

[0042] (4) Weigh 73.17g ZnO and 26.83g SiO respectively 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 850°C for 2 hours to synthesize Zn 2 SiO 4 compound.

[0043] (5) Weigh 69.31g Ba(OH) respectively 2 `6H 2 O and 30.69gH ...

Embodiment 2

[0046] (1) Weigh 21.85g BaCO respectively 3 , 37.26g Nd 2 o 3 and 40.89g TiO 2 , mixed ball milling, passing through a 40-mesh standard sieve, and calcining at 1180°C for 4 hours to synthesize a barium-neodymium-titanium compound;

[0047] (2) Accurately weigh 74.47gBi 2 o 3 and 25.53TiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 850°C for 2 hours to synthesize Bi 2 Ti2O 7 compound;

[0048] (3) Accurately weigh 55.62g CaCO 3 and 44.38TiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 1260°C for 2 hours to synthesize CaTiO 3 compound;

[0049] (4) Weigh 57.69g ZnO and 42.31g SiO respectively 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 900°C for 2 hours to synthesize ZnSiO 3 compound.

[0050] (5) Weigh 39.14gCuO and 60.86gH respectively 3 BO 3 Ball milling, drying, crushing, passing through a 40-me...

Embodiment 3

[0053] (1) Weigh 21.85g BaCO respectively 3 , 37.26g Nd 2 o 3 and 40.89g TiO 2 , mixed ball milling, passed through a 40-mesh standard screen, and calcined at 1160°C for 4 hours to synthesize a barium-neodymium-titanium compound;

[0054] (2) Accurately weigh 79.55gBi 2 o 3 and 20.45gTiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 800°C for 2 hours to synthesize Bi 4 Ti 3 o 12 compound;

[0055] (3) Accurately weigh 55.62g CaCO 3 and 44.38TiO 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 1270°C for 2 hours to synthesize CaTiO 3 compound;

[0056] (4) Weigh 73.17g ZnO and 26.83g SiO respectively 2 , mixed by ball milling, dried, crushed, passed through a 40-mesh standard sieve, and calcined at 850°C for 2 hours to synthesize Zn 2 SiO 4 compound.

[0057] (5) Weigh 69.31g Ba(OH) respectively 2 `6H 2 O and 30.69gH 3 BO 3 Ball milling, drying, crushing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com