Method for preparing graphene

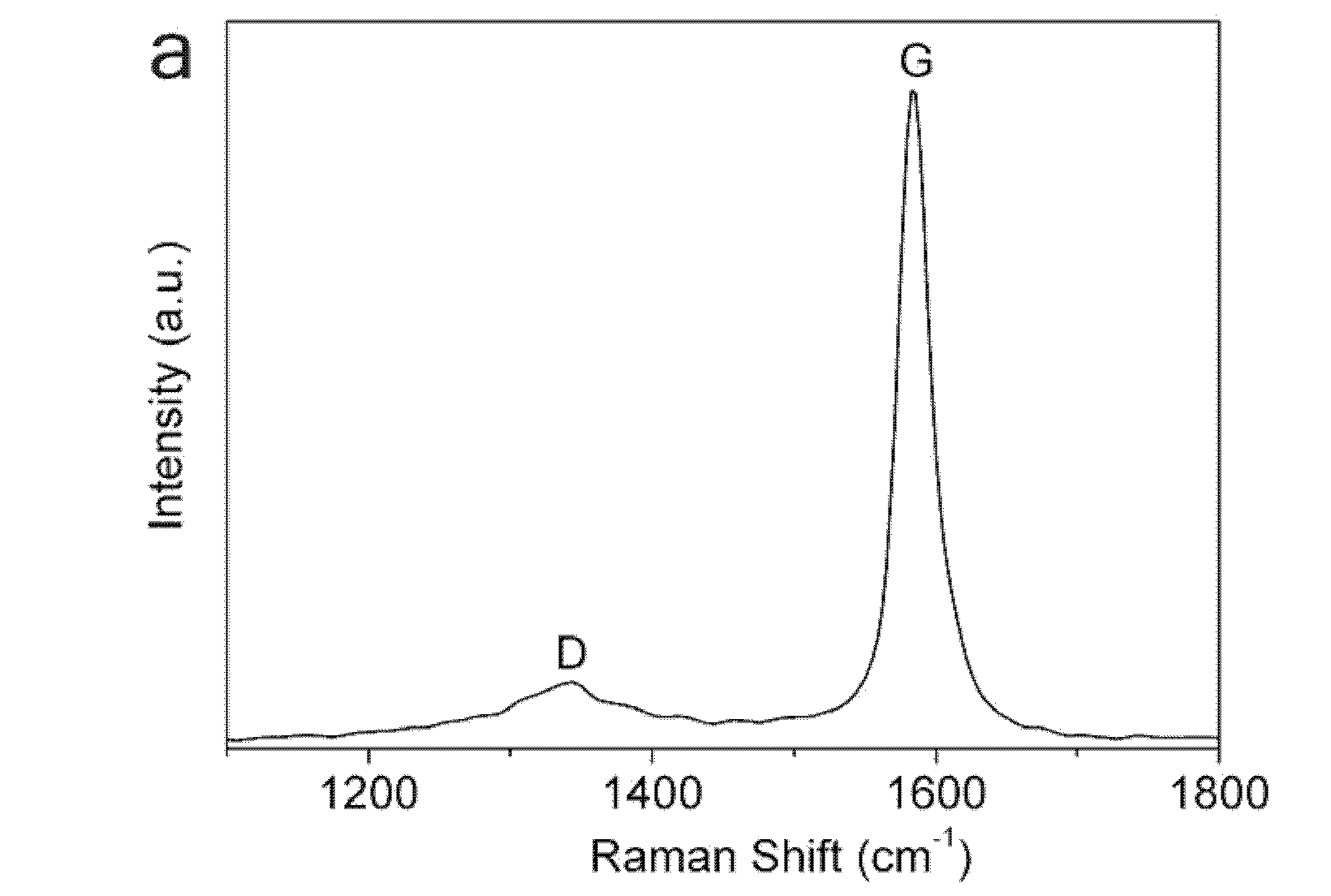

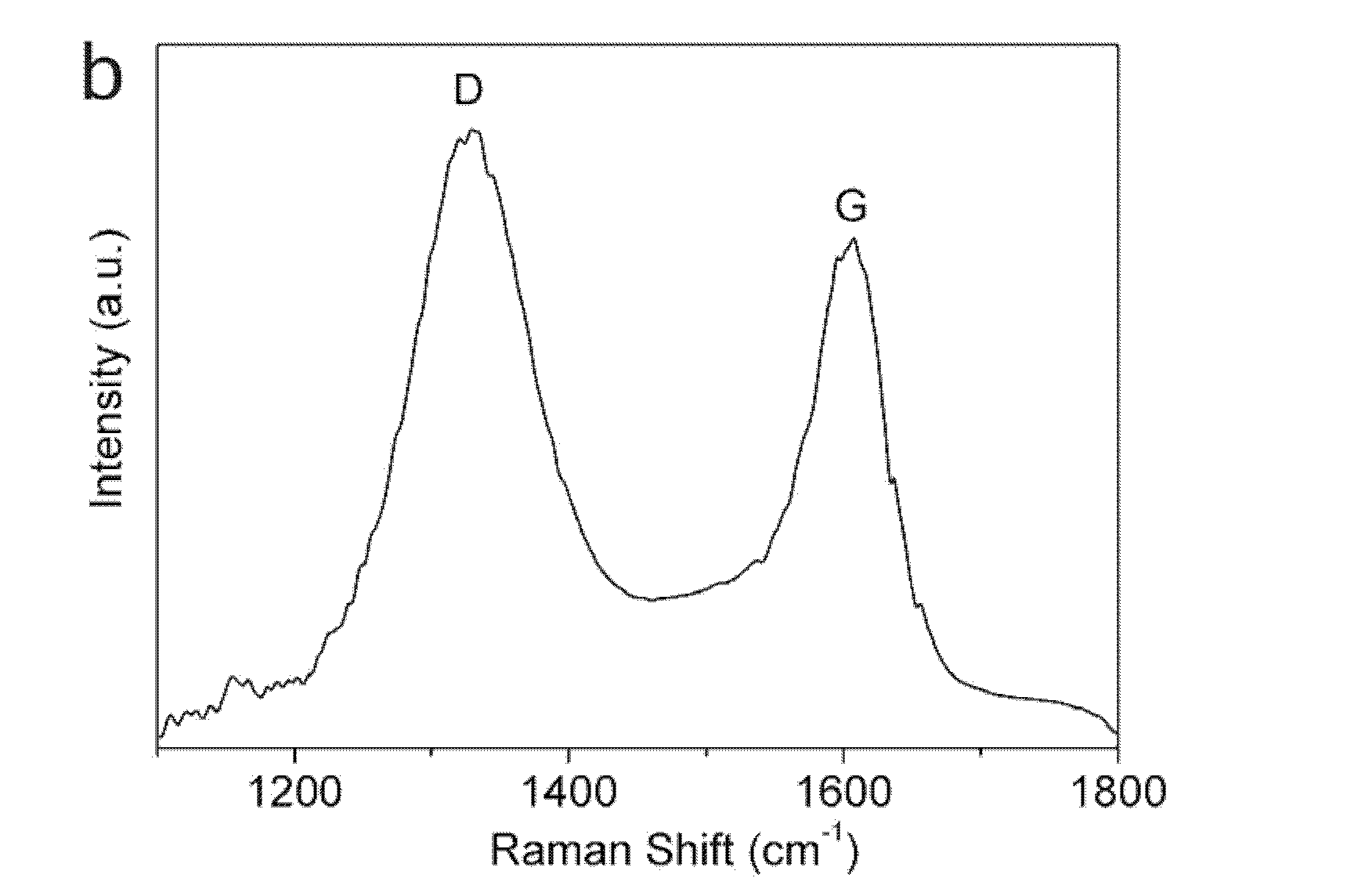

A technology of graphene and graphite, which is applied in the field of nanomaterials, can solve the problem of not being able to meet the large-scale demand for energy storage materials and functional composite materials, the low production efficiency of mechanical exfoliation and epitaxial growth methods, and affecting the quality and performance of graphene, such as electrical conductivity. and other issues to achieve good quality, easy large-scale production, and reduced structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of graphene, comprising:

[0024] Graphene is obtained by reacting graphite in an acid solution containing an oxidizing agent.

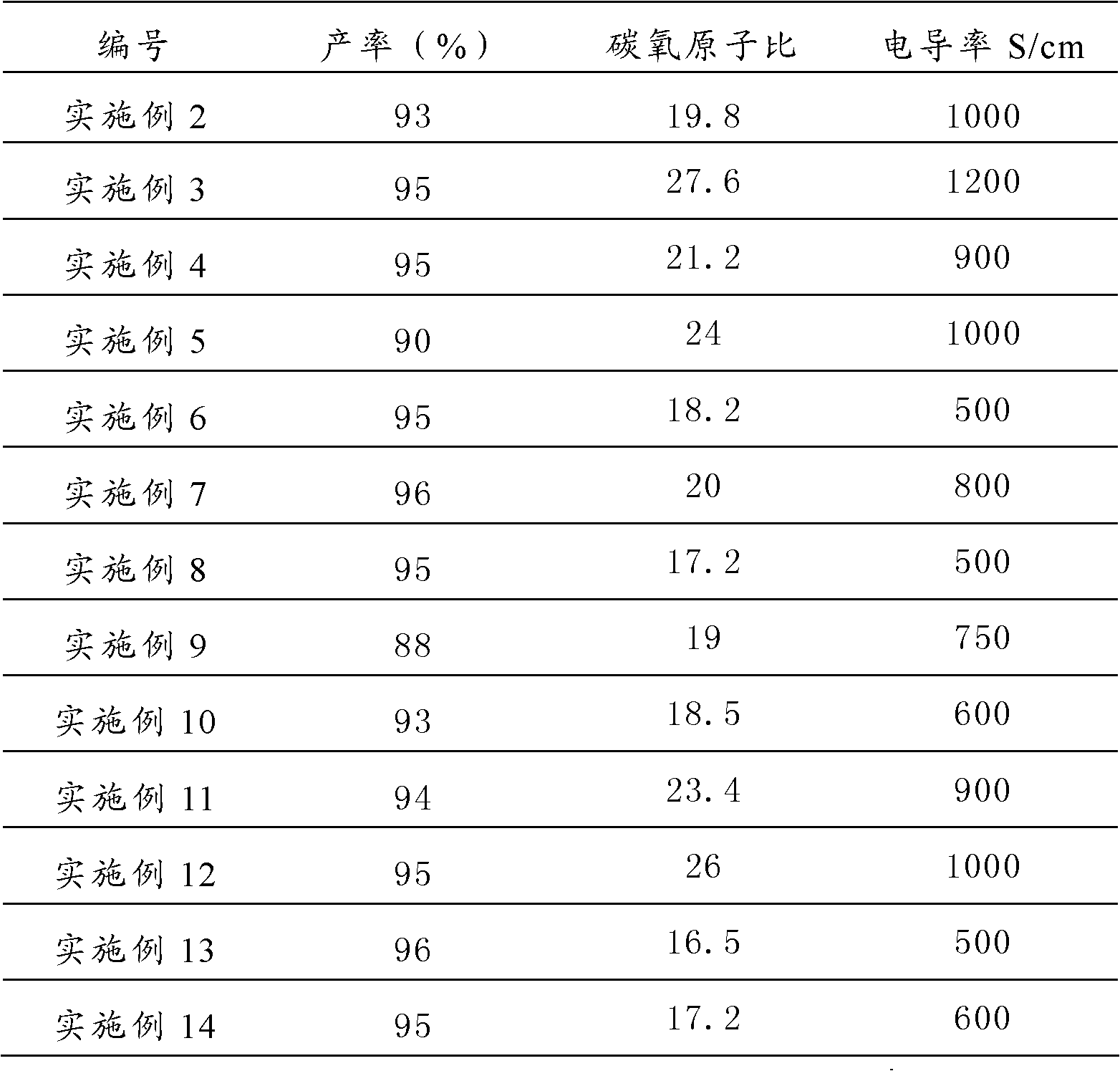

[0025] According to the present invention, the carbon to oxygen atomic ratio in the reacted product is greater than 5, more preferably greater than 10, more preferably greater than 14, more preferably greater than 16, and more preferably greater than 20.

[0026] According to the present invention, the acid in the acid solution is one or more combinations of nitric acid, sulfuric acid, perchloric acid, hypochlorous acid, nitrous acid, chlorosulfonic acid, acetic acid, oxalic acid, but not limited thereto. The oxidant is nitric acid, sulfuric acid, perchloric acid, hypochlorous acid, nitrous acid, chlorosulfonic acid, dichromate, perchlorate, chlorate, hypochlorite, persulfate, hydrogen peroxide, peroxide combination of one or more of them, but not limited thereto. The solvent in the acid so...

Embodiment 1

[0037] The first step, potassium dichromate is mixed with 69wt% nitric acid aqueous solution, then add graphite, graphite: nitric acid: potassium dichromate: water is 1: 20: 10: 9 according to weight ratio, reacts 1 hour then at 40 ℃ Afterwards, wash with water to neutrality and dry;

[0038] In the second step, the product obtained in the first step is incubated at 900° C. for 1 minute, and then cooled to room temperature;

[0039] In the third step, the product in the second step is ground for 5 hours in a high-energy ball mill or a sand mill;

[0040] In the fourth step, the product in the third step is dispersed in ethanol, and subjected to ultrasonic treatment for 1 hour to obtain graphene with a yield of 96%, and the carbon-to-oxygen atomic ratio of the product is 21.2.

Embodiment 2

[0042] The first step, potassium dichromate is mixed with 69wt% nitric acid aqueous solution and a certain amount of ethanol, then add graphite, graphite: concentrated nitric acid: potassium dichromate: water: ethanol is 1: 20: 10: 9 according to weight ratio : 10, then after reacting for 1 hour at 40°C, wash with water to neutrality and dry;

[0043] In the second step, the product obtained in the first step is incubated at 900° C. for 1 minute, and then cooled to room temperature;

[0044] In the third step, the product in the second step is ground for 5 hours in a high-energy ball mill or a sand mill;

[0045] In the fourth step, the product in the third step is dispersed in ethanol, and subjected to ultrasonic treatment for 1 hour to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com