Method for preparing graphene sheet

A technology of graphene sheet and graphite, which is applied in the field of graphene sheet preparation, can solve the problems that graphene cannot be prepared in batches, and achieve the effects of less structural defects, high efficiency, and good electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

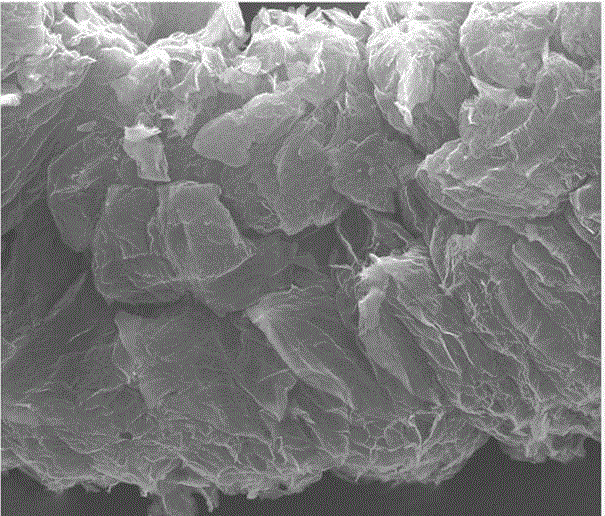

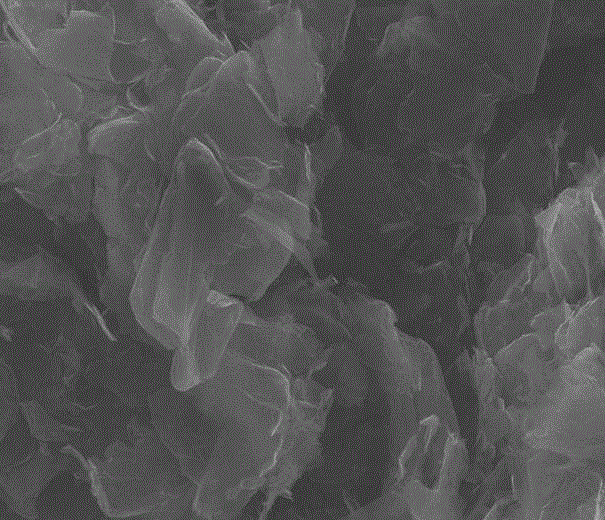

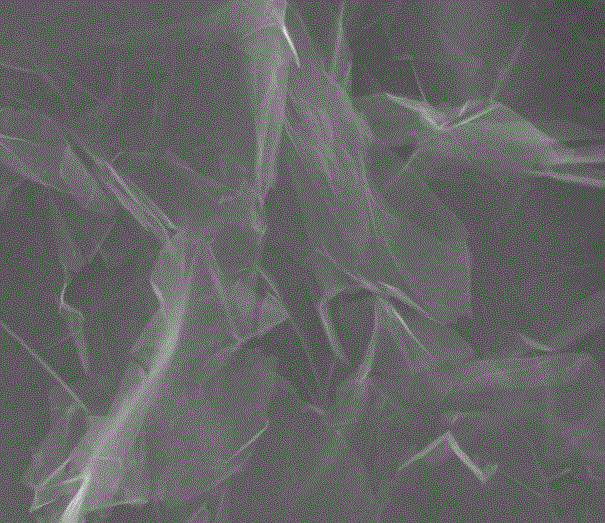

Image

Examples

Embodiment 1

[0044] (1) Take a certain amount of expanded graphite and expand it in a muffle furnace at 400°C, and transfer the expanded graphite to ammonia water (NH 3 h 2 O) mechanically stirring in the solution for 30 minutes and then standing still for 5 hours, then vacuum suction filtration and washing with deionized water to neutrality, then transfer it to an ethanol solution for ultrasonic dispersion for 12 hours, then suction filtration and drying to obtain micro-nano graphene sheets;

[0045] (2) Transfer the dried micro-nano graphene sheets to oleum for 2 h, then filter and transfer to 5% by mass H 2 o 2 After soaking in the solution for 5h, filter and dry;

[0046] (3) Put the dried micro-nano graphene sheets into a constant temperature tank with a saturated ammonium carbonate solution at a constant temperature of 50°C, ultrasonically disperse for 45 minutes, then mechanically stir for 2 hours, then stand for 8 hours for suction filtration, and dry at low temperature to obtain...

Embodiment 2

[0049] (1) Take a certain amount of expanded graphite and expand it in a muffle furnace at 600°C, and transfer the expanded graphite to NH 3 h 2 O solution was mechanically stirred for 30 minutes and then stood still for 5 hours, then vacuum filtered and washed with deionized water until neutral, then transferred to an ethanol solution for ultrasonic dispersion for 10 hours, and then dried by suction to obtain micro-nano graphene sheets;

[0050] (2) Transfer the dried micro-nano graphene sheets to oleum for 4 hours, then filter and transfer to 5% by mass H 2 o 2 After 5h in solution, filter and dry;

[0051] (3) Put the dried micro-nano graphene sheet into a constant temperature tank filled with ethanol at a constant temperature of 50°C, ultrasonically disperse it for 45 minutes, then mechanically stir it for 2 hours, then let it sit for 6 hours, suction filter, and dry at low temperature to obtain the intercalated micro-nano Graphene sheets; transfer the intercalated nano...

Embodiment 3

[0054] (1) Take a certain amount of expanded graphite and expand it in a muffle furnace at 800°C, transfer the expanded graphite to NaOH solution and mechanically stir for 30 minutes, then stand still for 6 hours, then vacuum filter and wash with deionized water until neutral, It was then transferred to an ethanol solution for ultrasonic dispersion for 15 hours, and then dried by suction to obtain micro-nano graphene sheets;

[0055] (2) Transfer the dried graphite nanosheets to oleum and concentrated nitric acid (volume ratio 1:1) for immersion for 2 hours, then filter and transfer to 10 mass% H 2 o 2 After 5h in solution, filter and dry;

[0056] (3) Put the dried micro-nano graphene sheet into a constant temperature tank filled with ethyl acetate at a constant temperature of 60°C, ultrasonically disperse it for 60 minutes, then mechanically stir it for 2 hours, then let it sit for 8 hours, suction filter, and dry at low temperature to obtain the intercalated nanographene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com