Method adopting a liquid phase stripping method to prepare grapheme and grapheme

A technology of liquid phase exfoliation and graphene, which is applied in the field of multi-layer graphene preparation, can solve the problems of complicated preparation process, decreased electrical conductivity of graphene, time-consuming, etc., and achieve the effect of good electrical conductivity and small structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

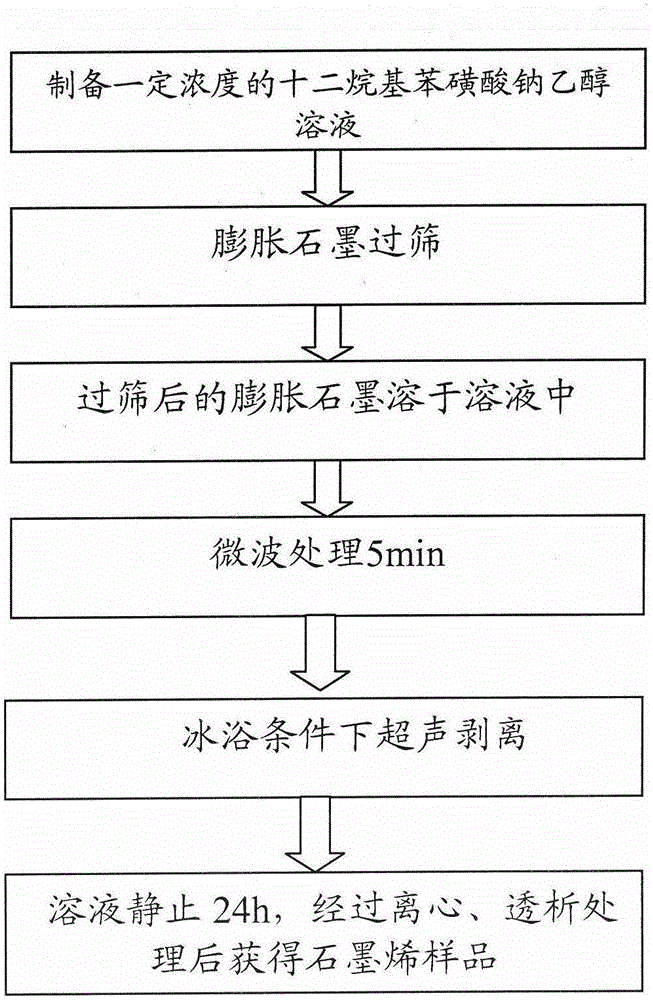

[0020] Such as figure 1 as shown, figure 1 A schematic process flow diagram of multilayer graphene prepared according to the preparation method of the present invention is shown. Specifically, the preparation method of the multilayer graphene includes: Step 1, preparing a certain concentration of sodium dodecylbenzenesulfonate ethanol solution; Step 2, sieving expanded graphite; Step 3, stirring the sieved The expanded graphite is dissolved in the solution prepared in step one; step four, the expanded graphite prepared in step three is treated with microwave for 5 minutes (min); step five, the solution after microwave treatment is ultrasonically stripped under ice bath conditions; step six 1. Resting the ultrasonically treated solution for 24 hours (h), and obtaining a graphene sample after centrifugation and dialysis.

[0021] In step five, a large amount of heat is released during the ultrasonic process, so that the temperature of the expanded graphite is higher, and the e...

Embodiment 1

[0025] Such as figure 2 Shown, surfactant uses sodium dodecylbenzene sulfonate (SDBS), and ultrasonic solvent selects ethanol and adopts magnetic stirring to completely dissolve the surfactant of certain quality in the solvent of certain volume (surfactant concentration is 0mg / mL, 4mg / mL, 6mg / mL), add expanded graphite passing through a 0.5mm pore size sieve, continue magnetic stirring and mixing, after fully mixing, microwave the mixed solution dispersed with expanded graphite for 5min, and then ultrasonicate the mixed solution for a period of time , to obtain a graphene dispersion. In order to separate the unexfoliated graphite and graphene, the obtained solution is centrifuged after standing still for a period of time, and the agglomerated graphene can be separated from the unaggregated graphene at the same time after centrifugation, and then the supernatant of the dispersion liquid is taken into a dialysis bag soaked in an aqueous solution for dialysis for a period of t...

Embodiment 2

[0027] Embodiment 2 first compared the influence of the ultrasonic stripping time on the preparation of graphene under the same surfactant concentration condition respectively, and obtained a better graphene preparation condition as when the surfactant concentration was 0mg / ml, and the ultrasonic stripping time was 15h, When the surfactant concentration is 4mg / ml, the ultrasonic stripping time is 10h, when the surfactant concentration is 6mg / ml, the ultrasonic stripping time is 10h, and then it is characterized by SEM, Raman and FTIR to compare the graphene prepared under three better conditions , and finally concluded that the best condition for preparing graphene is that the concentration of surfactant is 6mg / ml, and the ultrasonic stripping time is 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com