Microbial reduction of graphene oxide and preparation method for graphene

A graphene and graphene suspension technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of few layers, few defects and disorder, etc., to reduce structural defects, less environmental hazards, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

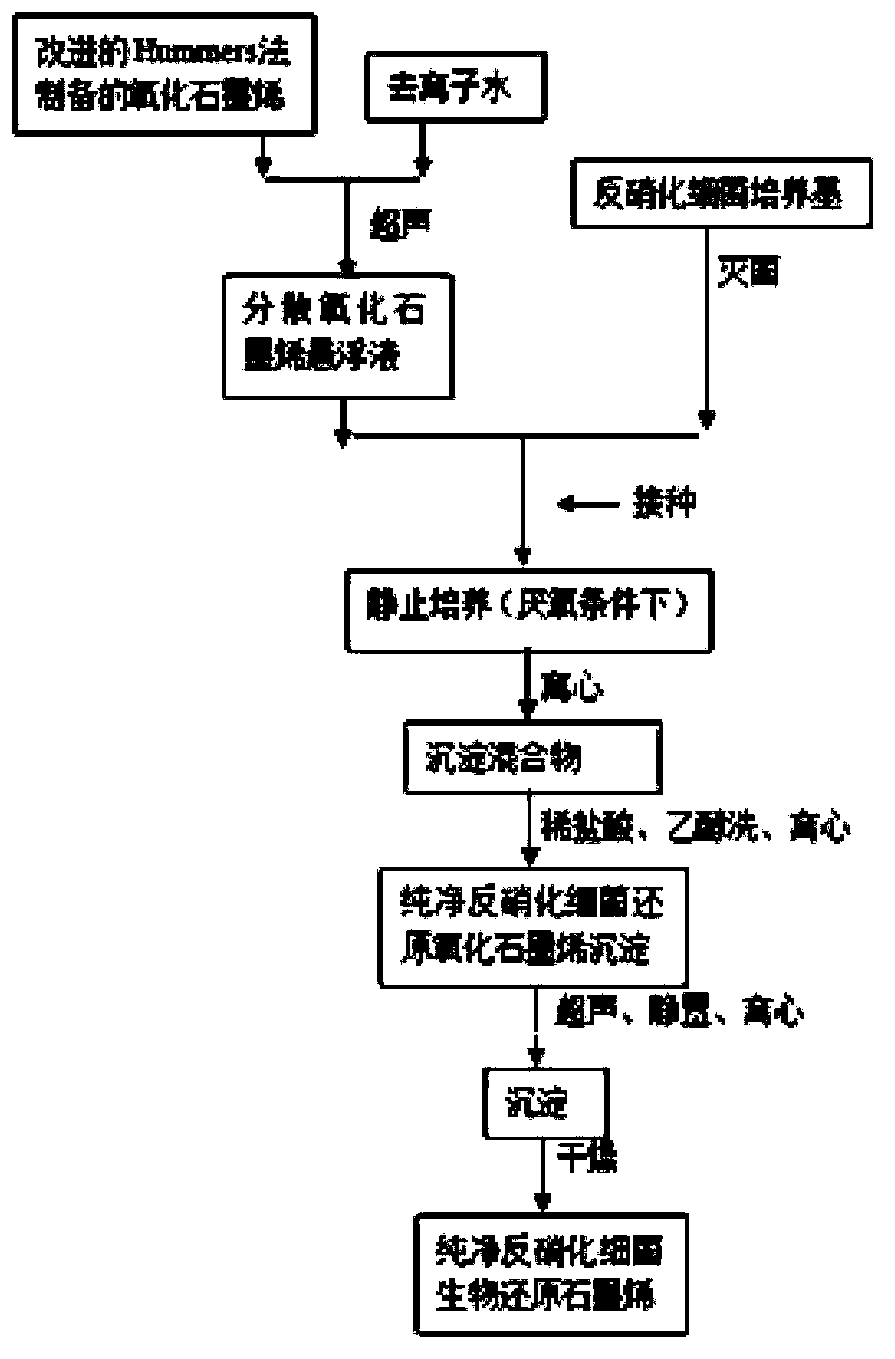

Method used

Image

Examples

Embodiment 1

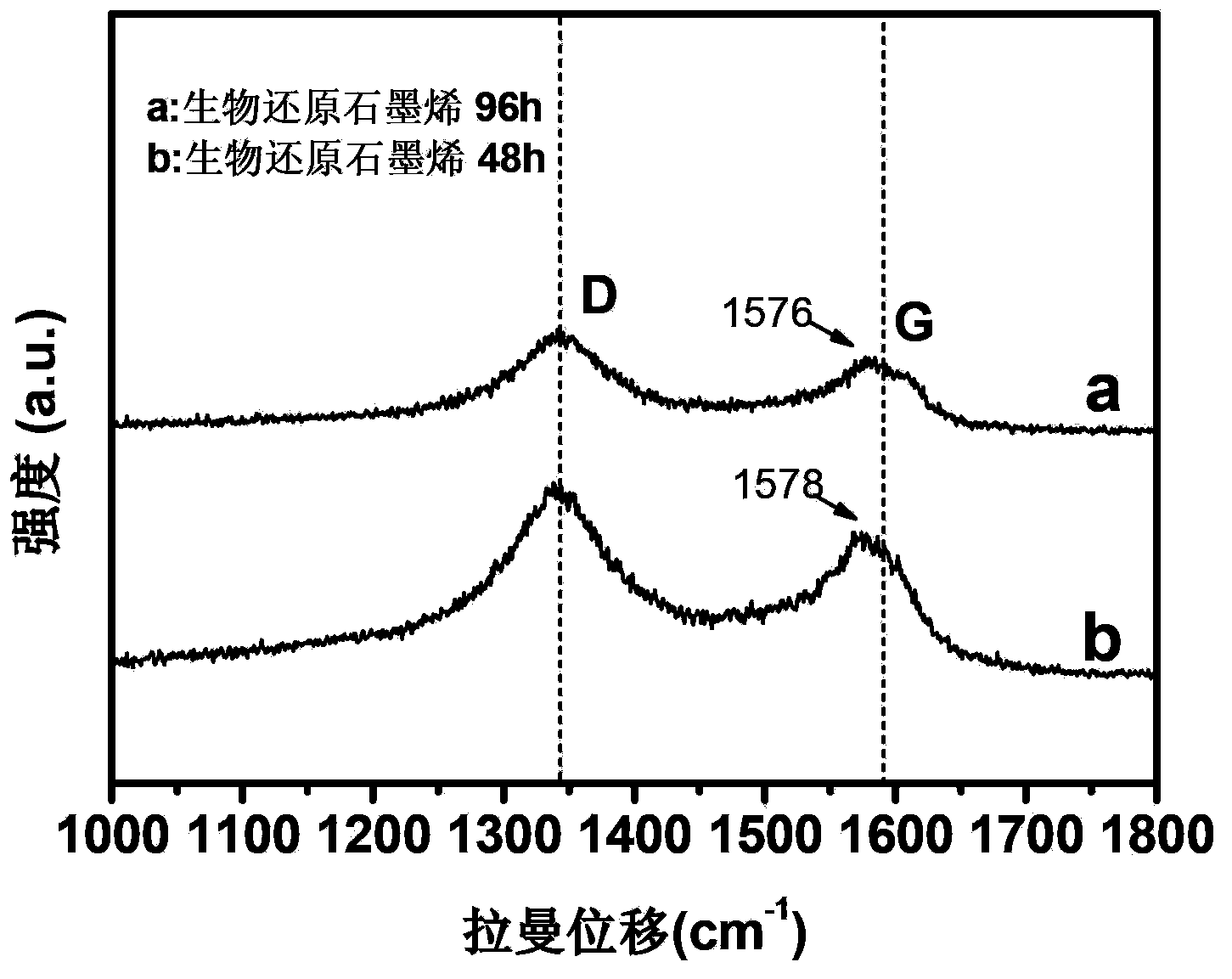

[0027] The invention relates to a biologically reduced graphene oxide, which comprises the following preparation steps: The first step is pretreatment of graphene oxide. Add 50mL, 2% graphene oxide to a 1L Erlenmeyer flask,

[0028] Add deionized water to 400mL in the conical flask, in a 250W ultrasonic cleaner, ultrasonically treat at room temperature for 30min, and obtain a brown suspension of graphene oxide with better dispersion properties;

[0029] The second step is to prepare 400mL of denitrifying bacteria culture medium, adjust the pH to 7.0 with 1:9 (v / v) dilute sulfuric acid, and distribute it to four 250mL Erlenmeyer flasks, each with a volume of 100mL. Use an autoclave at 121°C with a steam pressure of 0.1MPa to sterilize for 30 minutes, put the cooled medium in the ultra-clean workbench, add 100mL graphene oxide suspension to each bottle, and inject N into each bottle for 20 minutes. 2 , to remove dissolved oxygen. Among them, the denitrifying bacteria culture m...

Embodiment 2

[0036] A kind of biological reduction graphene oxide of the present invention comprises the following steps:

[0037] The first step is graphene oxide pretreatment. Add 50mL, 2% graphene oxide into a 1L conical flask, add deionized water to 400mL in a 1L conical flask, and in a 250W ultrasonic cleaning machine, ultrasonically treat at room temperature for 30min to obtain graphene oxide with good dispersion properties brown suspension;

[0038] The second step is to prepare 100mL of denitrifying bacteria culture medium, adjust the pH to 7.0 with 1:9 (v / v) dilute sulfuric acid, and distribute it to four 250mL Erlenmeyer flasks, each with a volume of 20mL. Use an autoclave at 121°C with a steam pressure of 0.1MPa to sterilize for 30 minutes, put the cooled medium in the ultra-clean workbench, add 100mL graphene oxide suspension to each bottle, and inject N into each bottle for 20 minutes. 2 , to remove dissolved oxygen. Among them, the denitrifying bacteria culture medium incl...

Embodiment 3

[0042] A kind of biological reduction graphene oxide of the present invention comprises the following steps:

[0043] The first step is graphene oxide pretreatment. Add 50mL, 2% graphene oxide into a 1L conical flask, add deionized water to 400mL in a 1L conical flask, and in a 250W ultrasonic cleaning machine, ultrasonically treat at room temperature for 30min to obtain graphene oxide with good dispersion properties brown suspension;

[0044] The second step is to prepare 400mL of denitrifying bacteria culture medium, adjust the pH to 7.0 with 1:9 (v / v) dilute sulfuric acid, and distribute it to four 250mL Erlenmeyer flasks, each with a volume of 100mL. Use an autoclave at 121°C with a steam pressure of 0.1MPa to sterilize for 30 minutes, put the cooled medium in the ultra-clean workbench, add 100mL graphene oxide suspension to each bottle, and inject N into each bottle for 20 minutes. 2 , to remove dissolved oxygen. Among them, the denitrifying bacteria culture medium inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com