Surface treatment method of tantalum sprayer for wet spinning

A technology of wet spinning and surface treatment, applied in the field of surface treatment of tantalum spinnerets, can solve the problem that the spinnability is not as good as that of precious metal spinnerets, and achieve the effects of excellent spinnability, lower production costs, and improved chemical fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

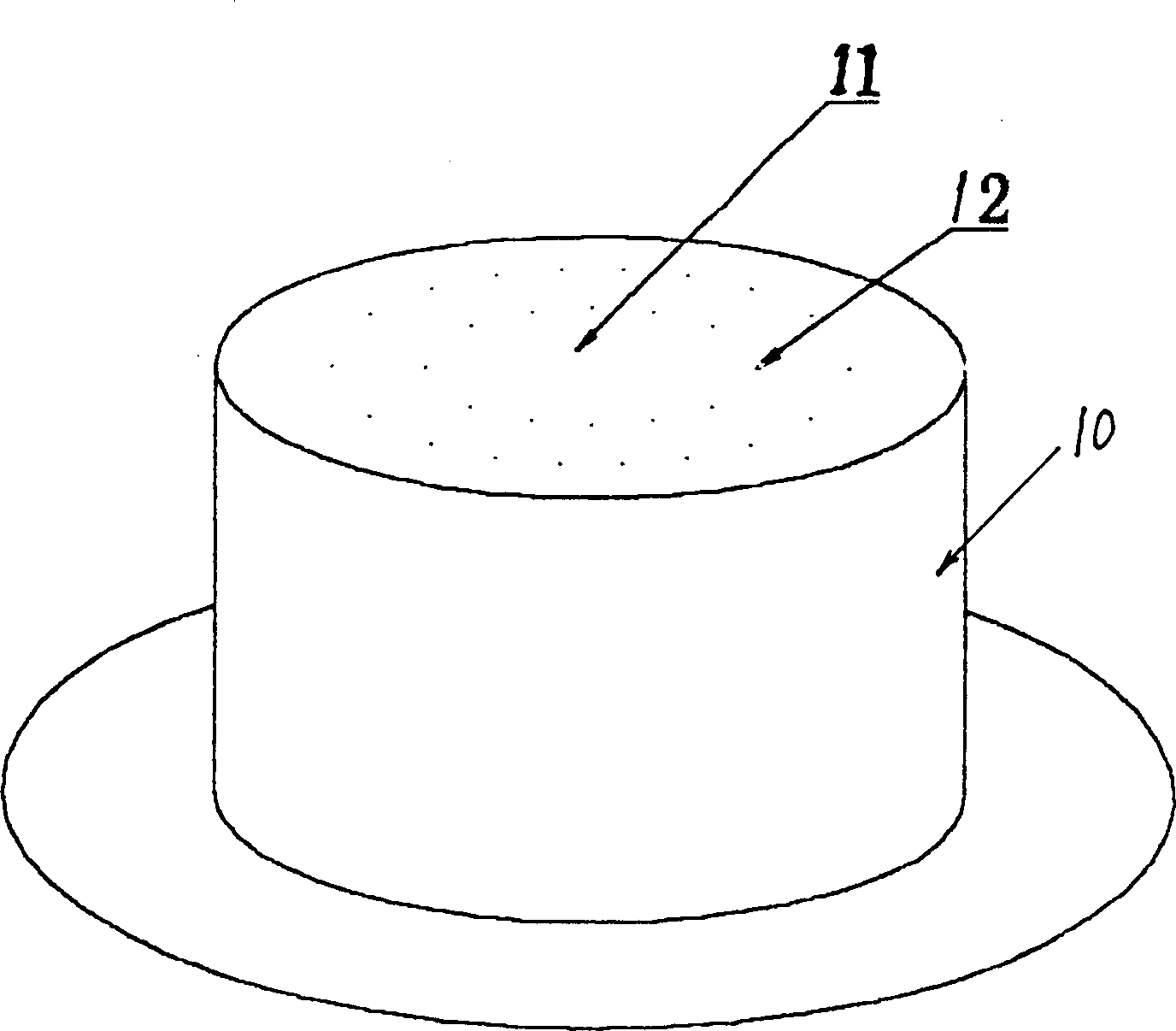

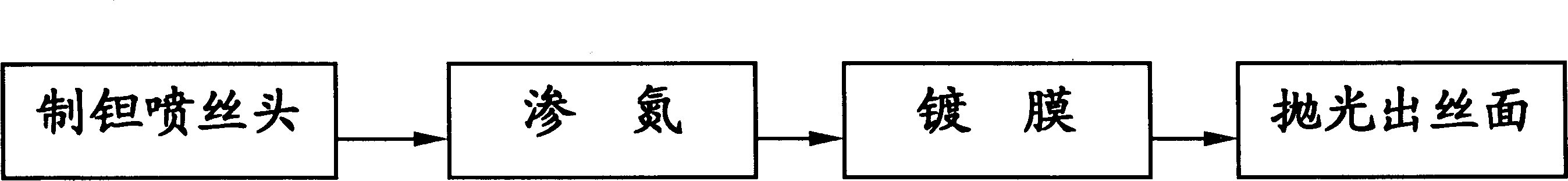

[0074] Step 1, process metal tantalum plate into tantalum spinneret with prior art, such as figure 1 As shown, the tantalum spinneret includes a body 10, the outer diameter of the spinneret outlet surface 11 is 12mm, the number of micropores 12 is 30, and the inner diameter of the micropores is 0.083±0.001mm.

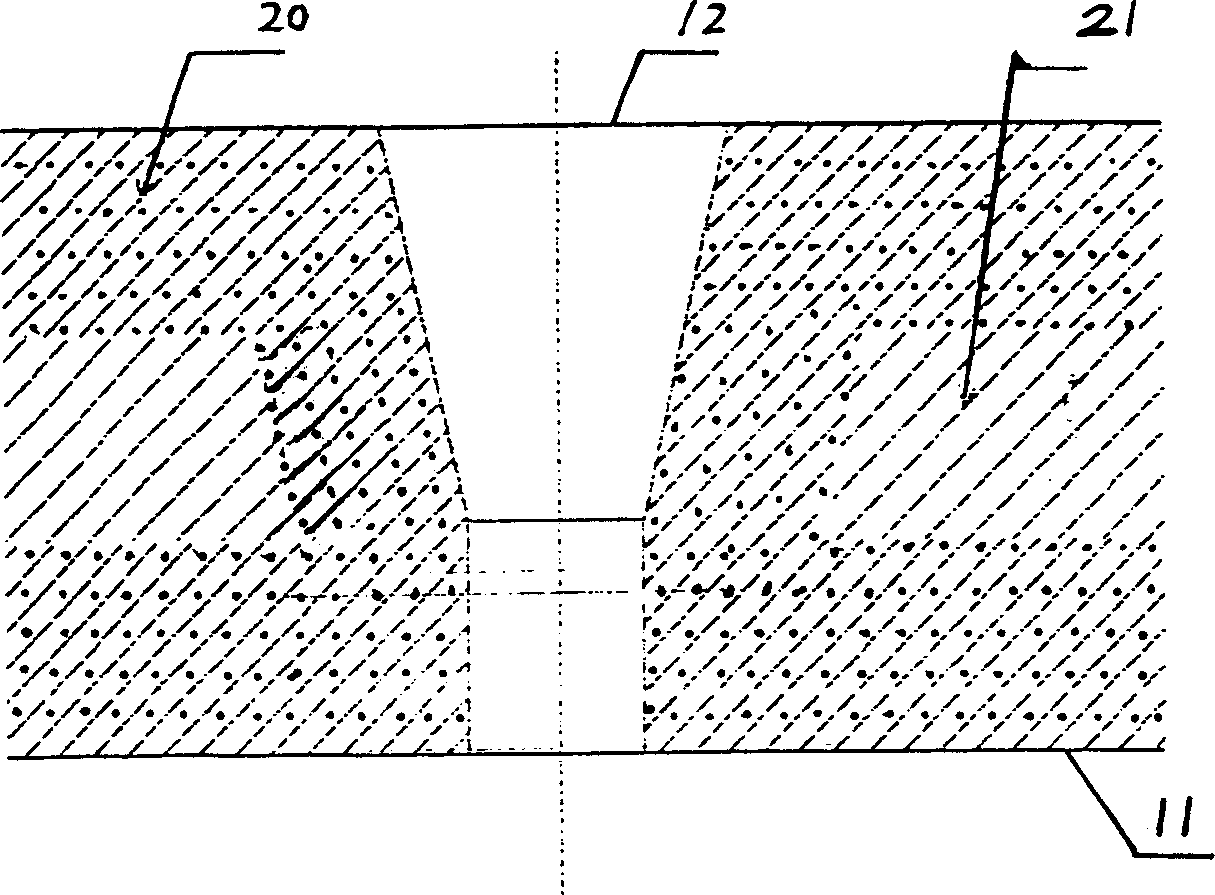

[0075] Step 2, nitriding: use the LD-25 ion nitriding furnace produced in Beijing, use the tantalum spinneret produced in step 1 as the cathode, the furnace temperature is 1000°C, the furnace pressure is 1000Pa, and the gas filled is nitrogen and hydrogen. Nitrogen: hydrogen = 1:3, nitriding for two hours, vacuum cooling to 100°C and taking out, after nitriding, the hardness of the tantalum spinneret is about HV900. Such as image 3 As shown, a nitrided layer 20 is formed on the surface of the tantalum spinneret.

[0076] Step 3. Coating: apply 10 volts of anode voltage to the molten lithium nitrate solution at 500°C, and react at constant voltage for 6 hours to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com