Semiconductor device, metal-insulator-metal capacitor and method for manufacturing same

A technology of metal capacitors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of pixel photosensitive loss, large space occupation, and high metal layer thickness, so as to reduce lateral Effect of optical crosstalk and space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

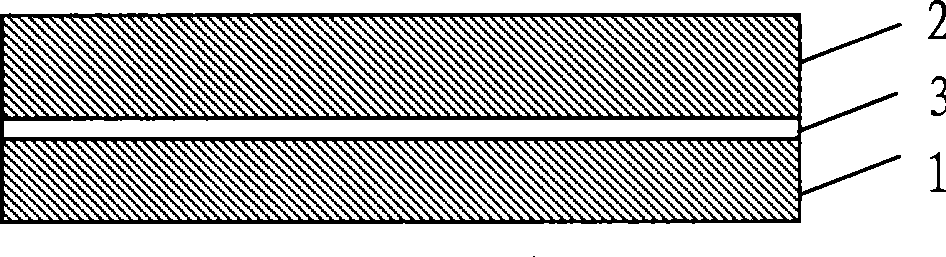

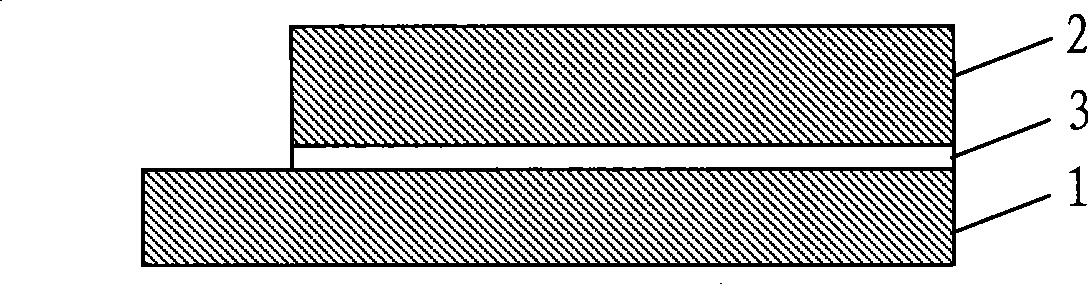

[0041] An embodiment of the metal-insulator-metal capacitor manufacturing method provided by the present invention is as follows: Figure 5 As shown, it mainly includes the following steps:

[0042] 11) providing a semiconductor substrate, depositing a first metal layer on the semiconductor substrate;

[0043] 12) patterning the first metal layer;

[0044] 13) depositing a passivation layer on the first metal layer;

[0045] 14) etching the passivation layer to form wiring holes;

[0046] 15) depositing a dielectric layer on the surface of the passivation layer;

[0047] 16) Etching part of the dielectric layer, retaining the required dielectric layer for making MIM capacitors;

[0048] 17) Covering and depositing a second metal layer on the surface of the dielectric layer and the passivation layer.

[0049] In the above embodiment, the passivation layer and the wiring hole are first formed on the first metal layer, and the required dielectric layer is formed according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com