Pit structure installation method

An installation method and pit technology, applied in building components, building structures, wine cellars, etc., can solve problems such as difficult correction, deviation error, rough and simple pit structure installation, etc., to improve stability and strength, The effect of reducing misalignment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

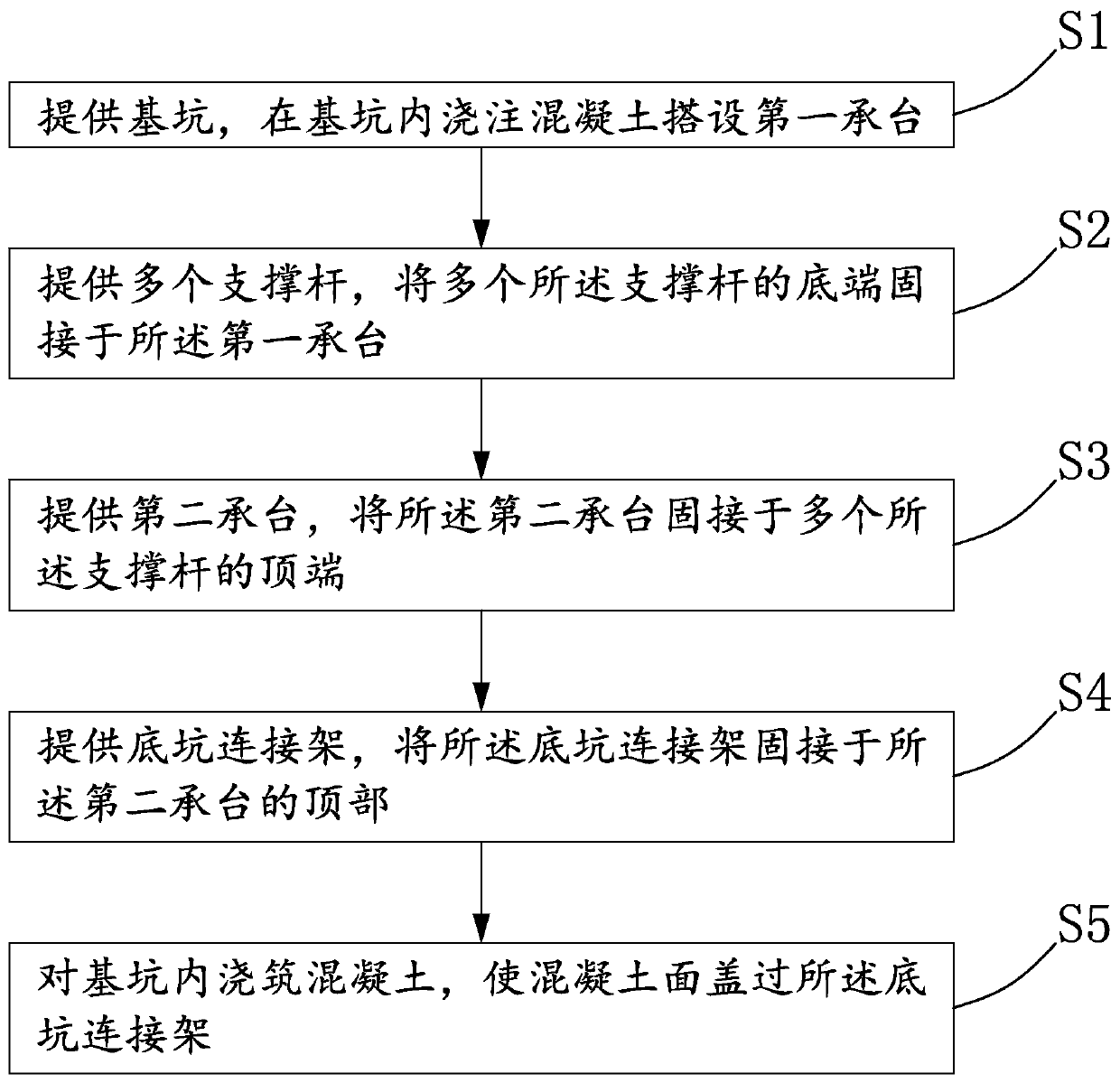

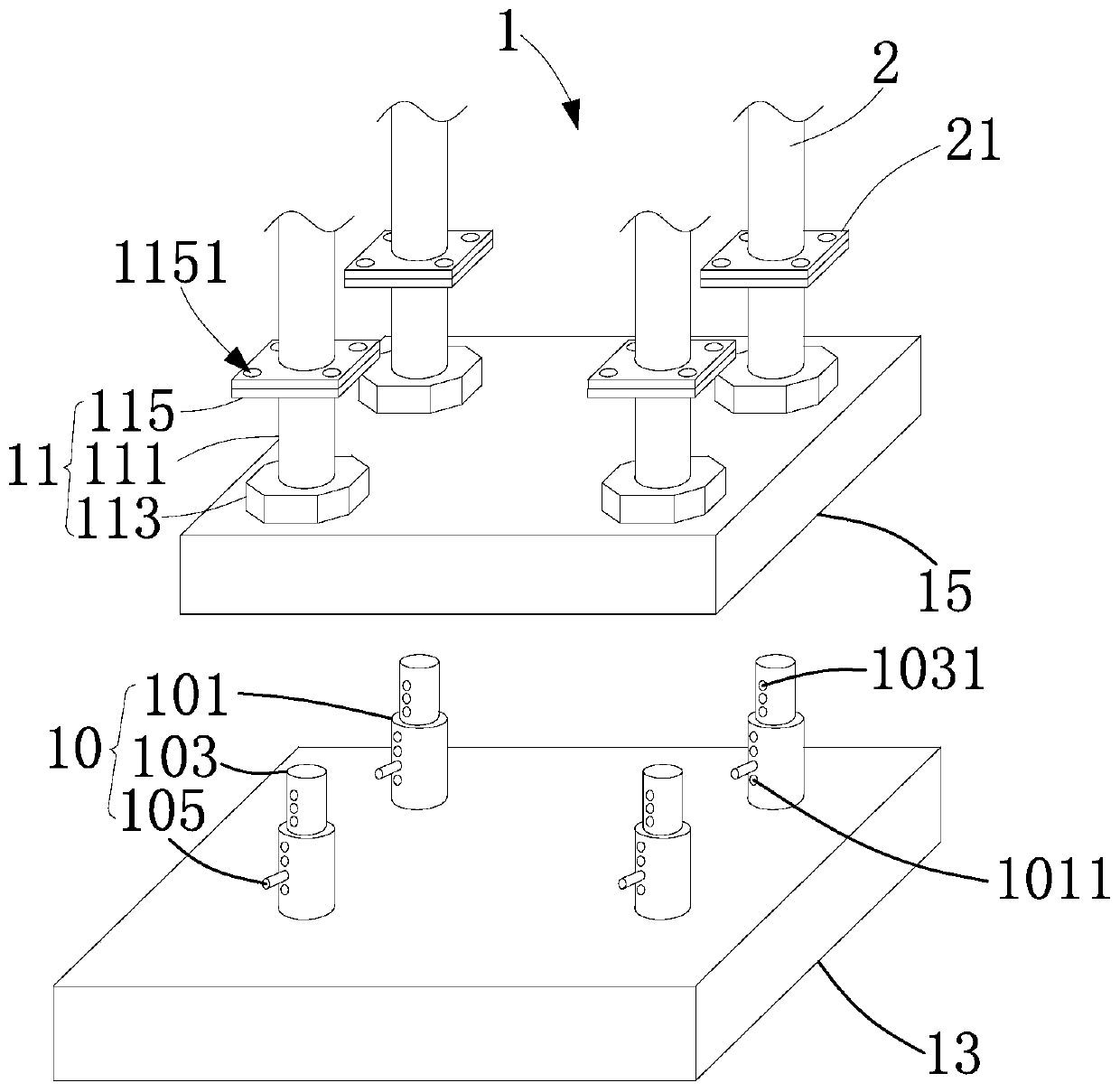

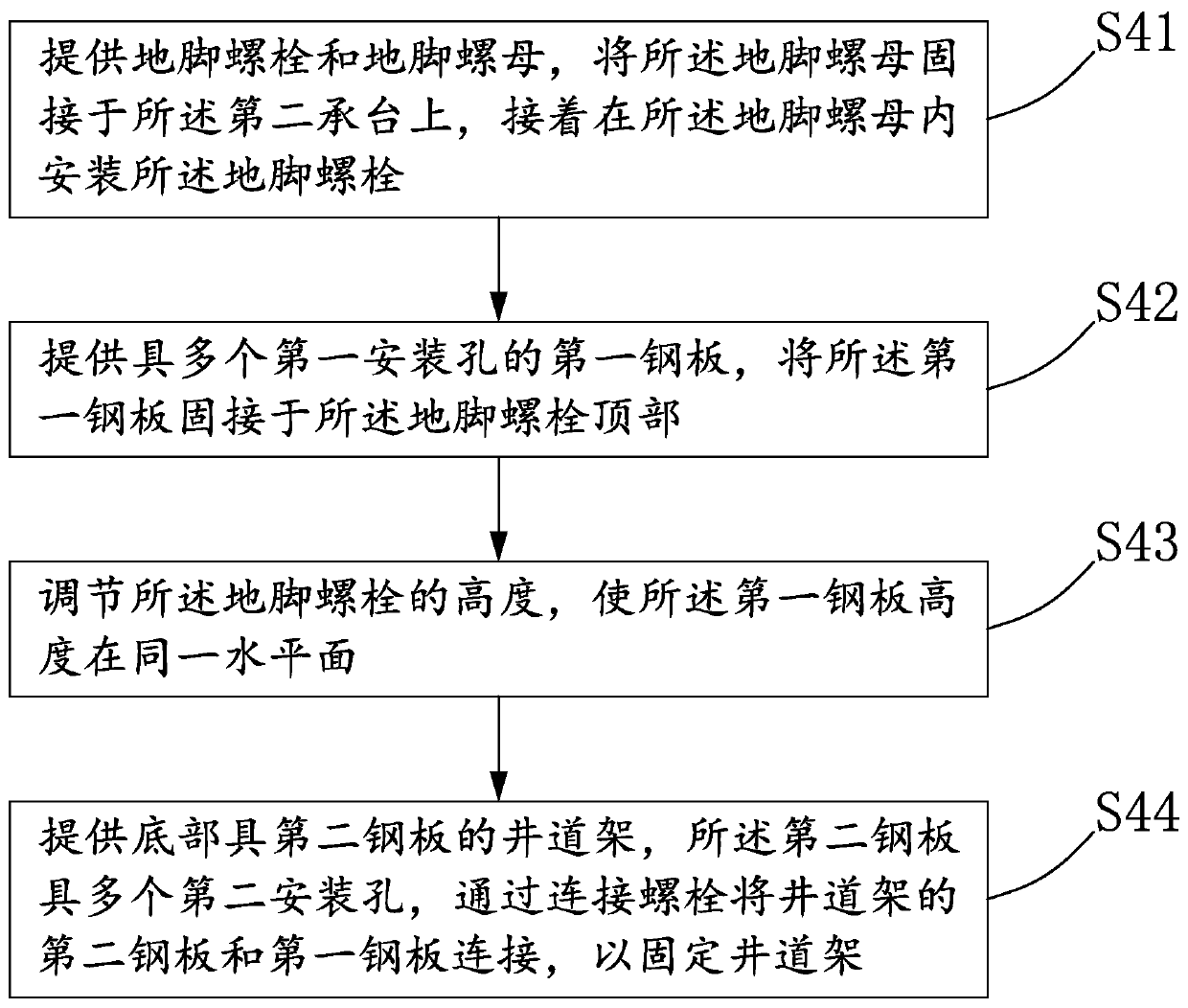

[0030] A pit structure installation method, please refer to figure 1 and figure 2 ,in, figure 1 It is a flow chart of the steps of the pit structure 1 installation method of the present invention; figure 2 It is a three-dimensional exploded view of the pit structure of the present invention. The installation method of the bottom pit structure includes the following steps:

[0031] Step S1, providing a foundation pit, pouring concrete into the foundation pit to erect the first platform 13;

[0032] Step S2, providing a plurality of support rods 10, and fixing the bottom ends of the plurality of support rods 10 to the first platform 13;

[0033] In this embodiment, the number of the support rods 10 is four, which are respectively arranged at the four corners of the first platform 13 .

[0034] Step S3, providing a second platform 15, and fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com