Pressure backfill type pipe connection piece

A pipe connector and pressure technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, passing components, etc., can solve the problems of affecting ground vegetation and normal use, large environmental damage, complex construction, etc., to achieve connection Good effect, good anti-corrosion effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

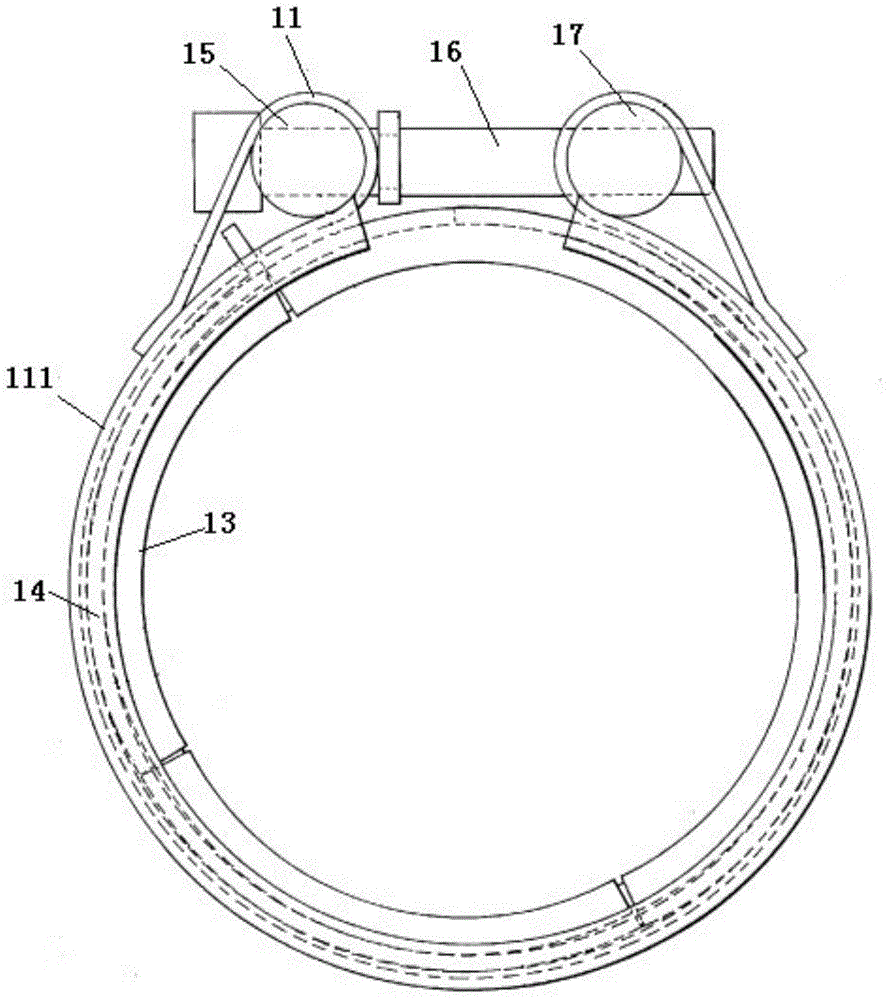

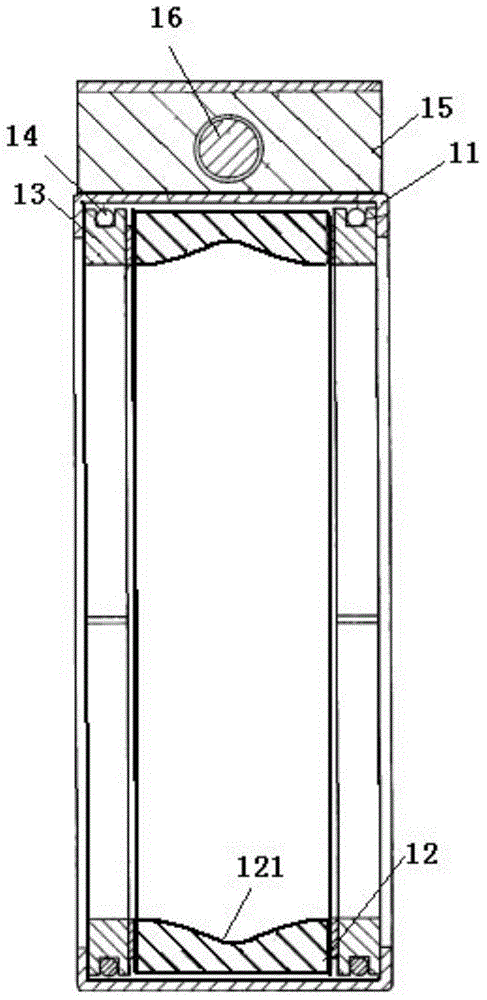

[0026] see Figure 1-2 , shows a pressure backfill pipe connection of the present invention.

[0027] The pressure backfill pipe connector mainly includes a tightening member 11 and an elastic compression ring 12, and the tightening member 11 is an open ring with a cross section of figure 2 In the U-shape shown, the elastic compression ring 12 is located on the inner edge of the tightening member 11 .

[0028] And a tightening bolt 16, left fixing rod 15 and right fixing rod 17, described left fixing rod 15 and right fixing rod 17 are respectively transversely fixed on the opening two sides of described tightening member 11, and the left fixing ring 15 The middle part is provided with a through hole for the clamping bolt 16 to pass through, and the middle part of the right fixing ring 17 is provided with an internal thread for the screwing of the clamping bolt 16, thus, the left fixing rod is connected by the clamping bolt 16 The screw fastening between 15 and the right fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com