DMD component, DLP light machine and DLP projection device

A component and host technology, applied in the field of optics and projection, can solve problems such as difficulty in ensuring fixed precision, low contact stability, and non-relative fixation, so as to improve production efficiency and product quality, improve accuracy and stability, The effect of ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further described below with reference to the accompanying drawings and exemplary embodiments, wherein like numerals in the drawings refer to like parts throughout. Also, if a detailed description of known art is not necessary to illustrate the features of the present invention, it will be omitted.

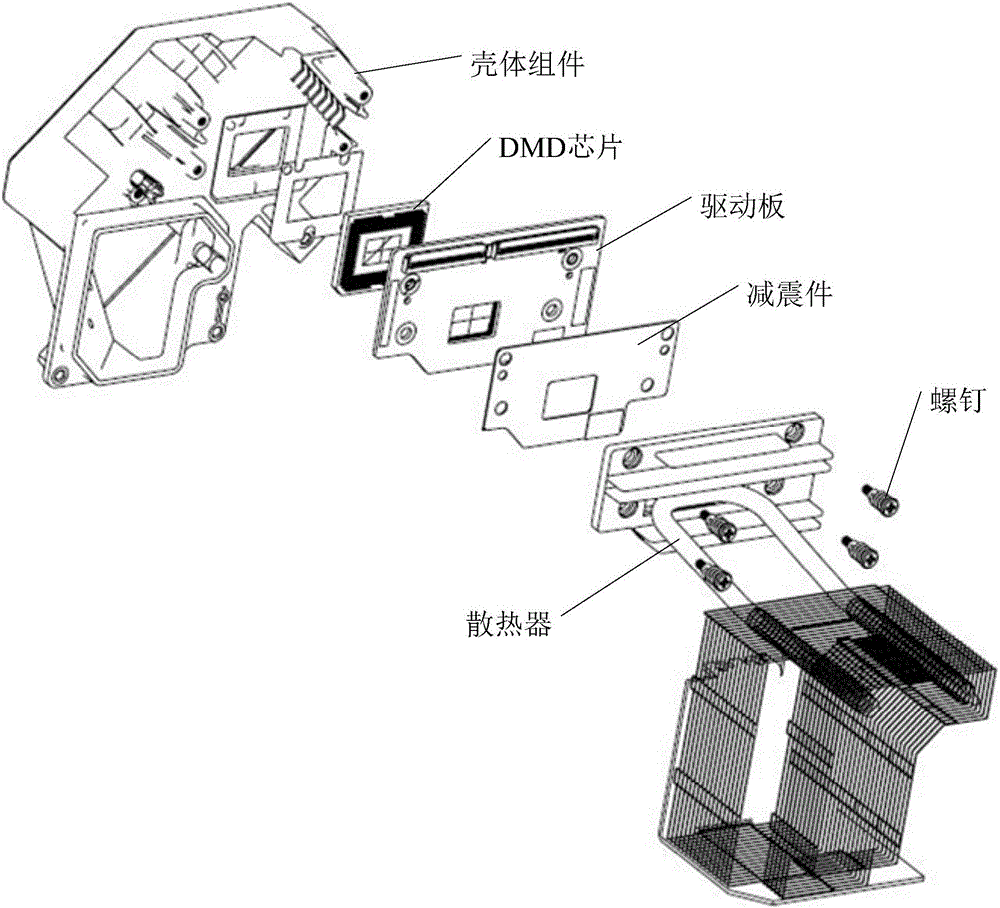

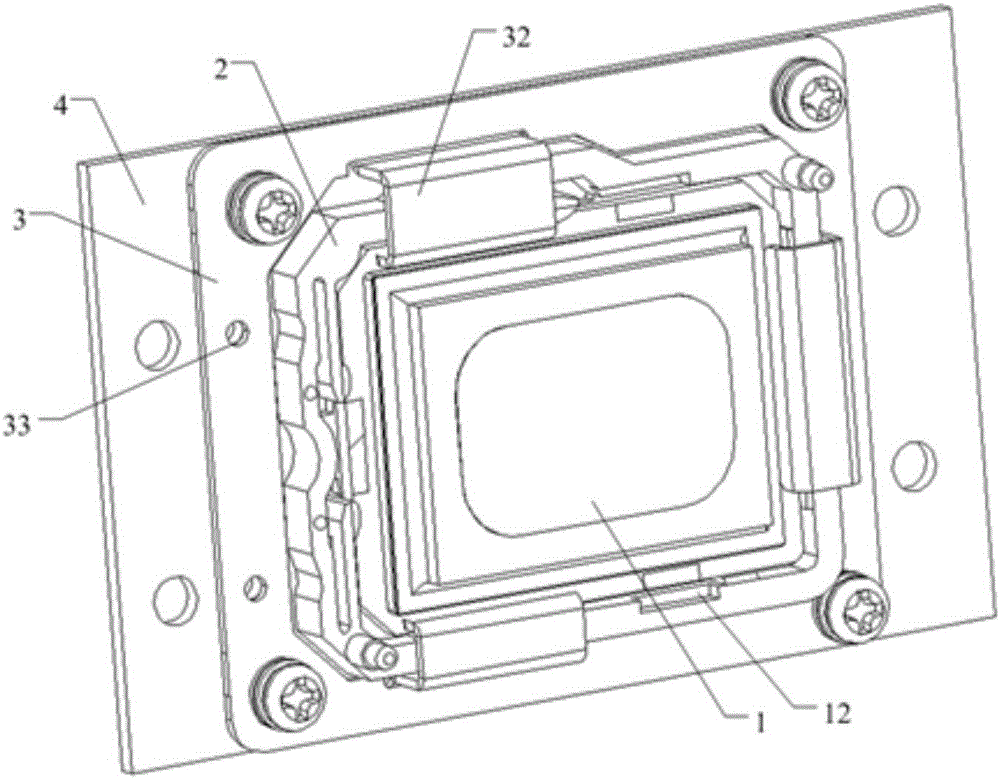

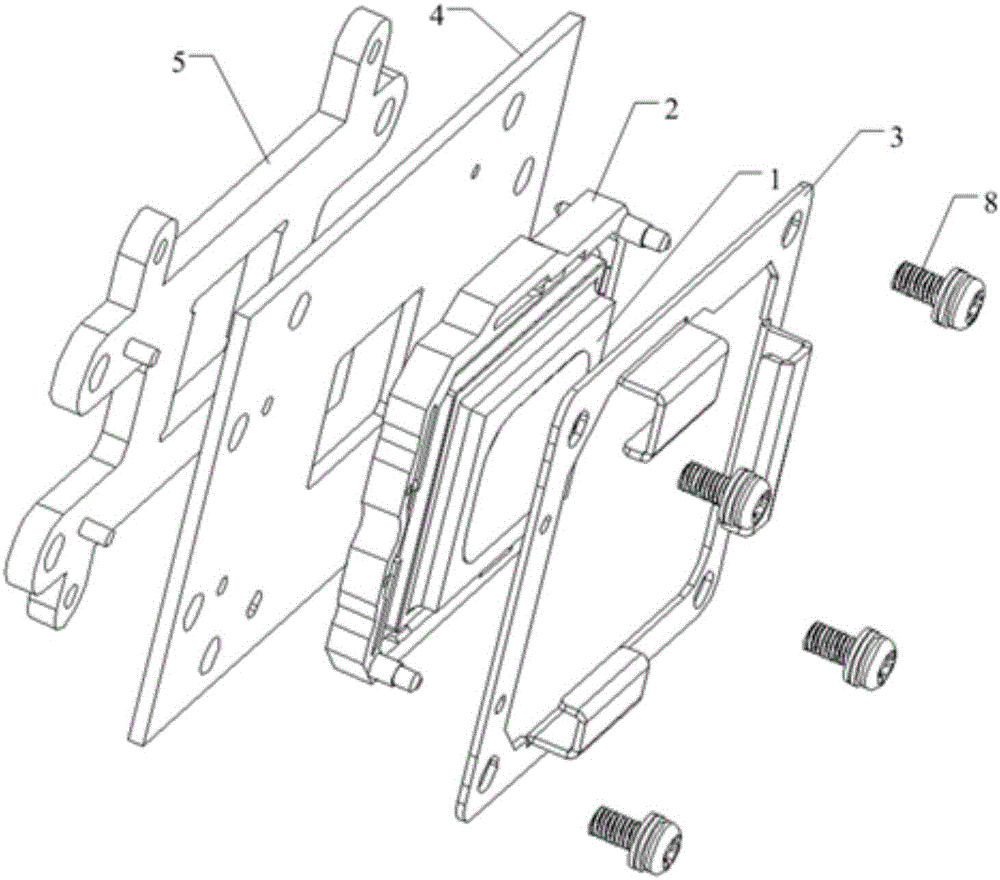

[0050] The schematic structural diagrams of a typical embodiment of a DMD assembly provided by the present invention are shown in 2 to 10. The DMD assembly includes a DMD fixing structure and a DMD chip 1 and a driving board 4 arranged on the DMD fixing structure, wherein, The DMD assembly includes a base 2 for mounting the DMD chip 1 , a support plate 5 and a fixing frame 3 for fixing the driving board 4 .

[0051] Wherein, the base 2 is provided with a mounting groove 22 for the embedded installation of the DMD chip 1 , and the mounting groove 22 has an elastic limiting structure 23 for mounting and fixing the DMD chip 1 installed therein. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com