Fabricated building structure

A building structure and prefabricated technology, used in building components, building structures, buildings, etc., to reduce costs, ensure connection quality, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

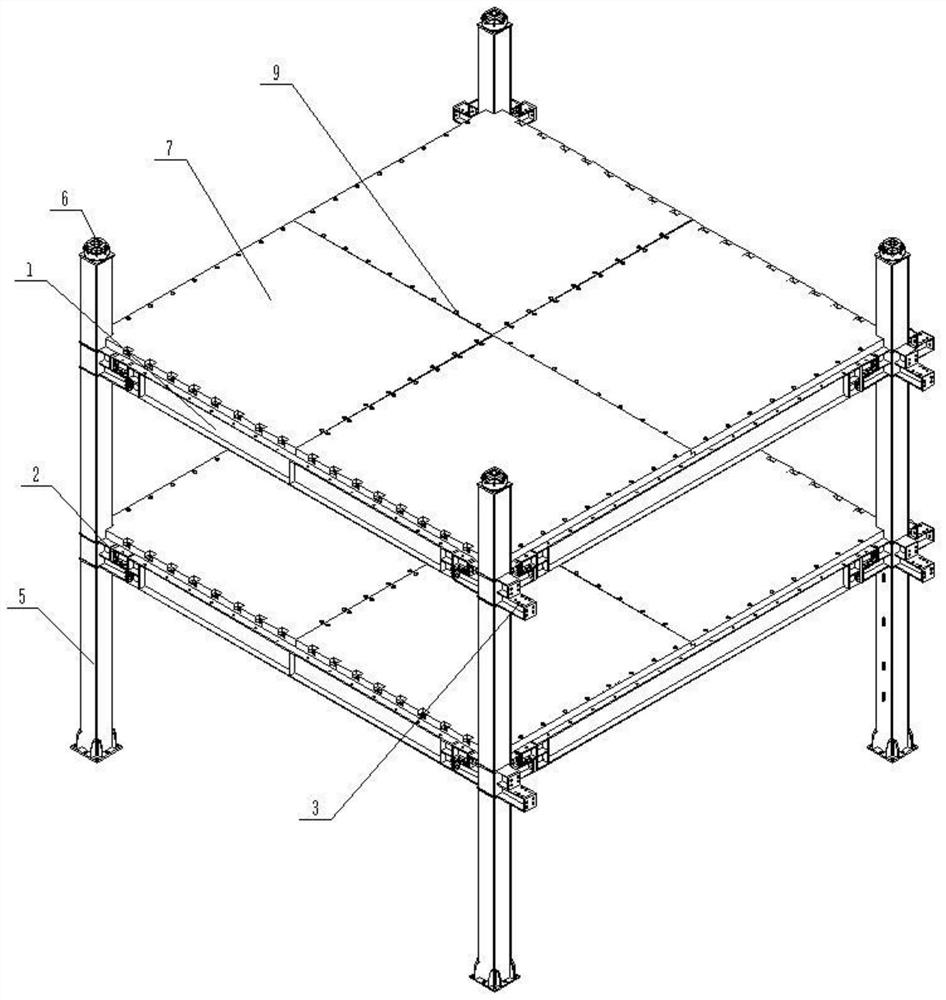

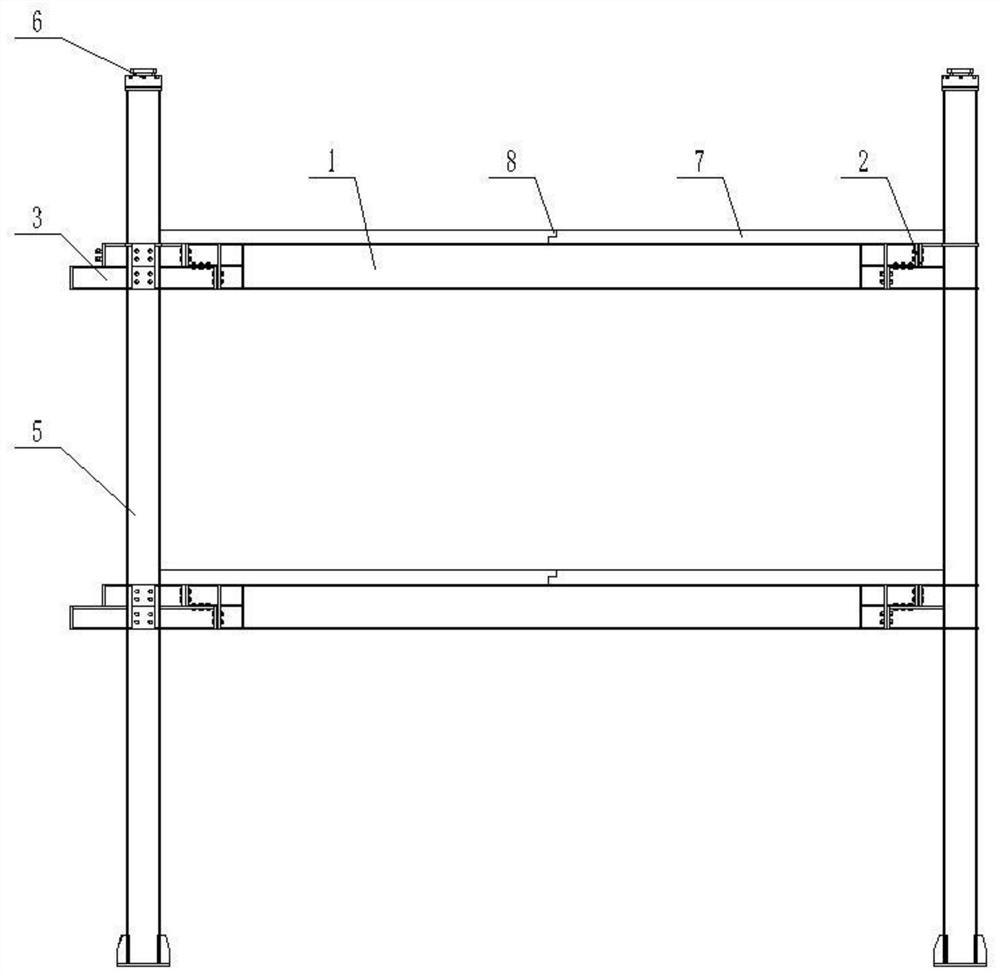

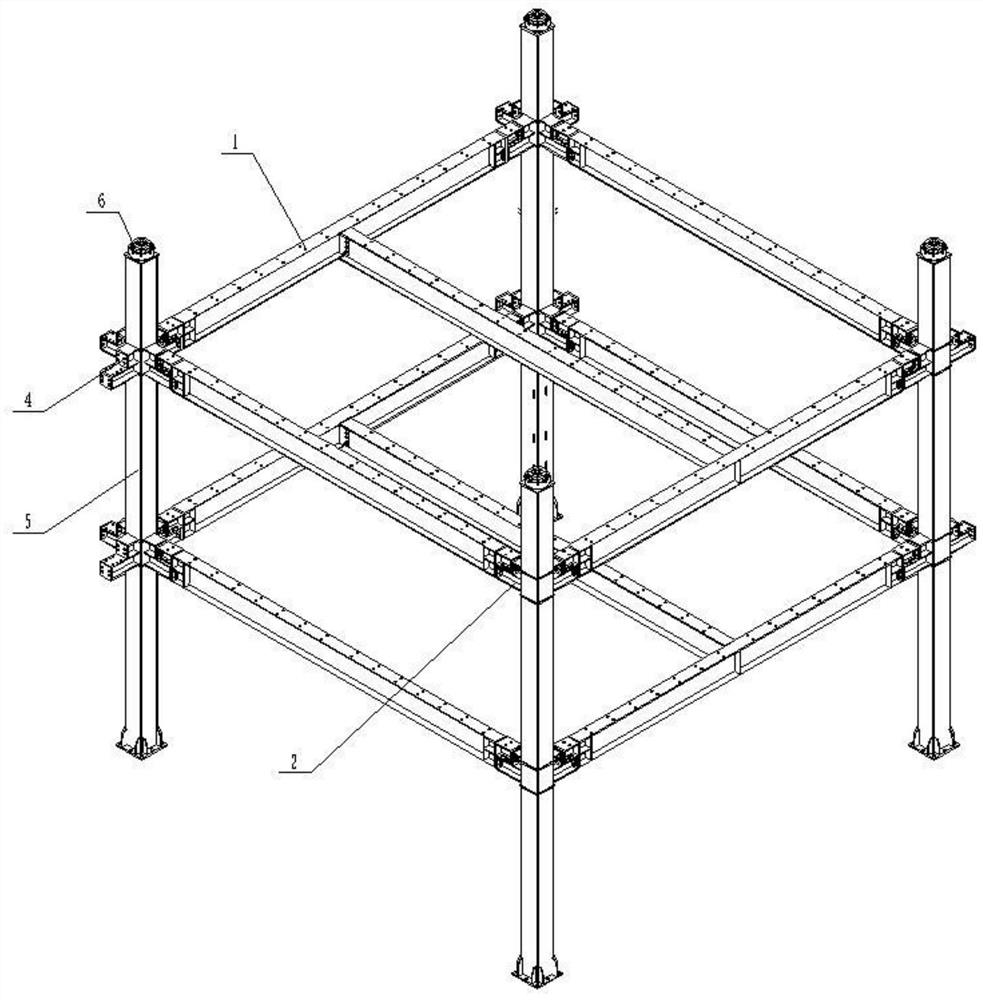

[0044] Such as Figure 1 to Figure 15As shown, a prefabricated building structure of the present invention includes a beam 1, an L-shaped node structure 2, a T-shaped node structure 3, a cross-shaped node structure 4, a column 5, a column connection node 6, and a floor plate body 7. The beam 1. The L-shaped node structure 2, the T-shaped node structure 3 and the cross-shaped node structure 4 form a main beam unit in the shape of a field, the cross-shaped node structure 4 is located at the center of the field, and the L-shaped node structure 2 is located at the center of the field. The four corners of the word, the T-shaped node structure 3 is located in the middle of the side of the word Tian, and the L-shaped node structure 2 and the T-shaped node structure 3, the T-shaped node structure 3 and the cross-shaped node structure 4 are connected with beams 1; the L-shaped node structure 2, the T-shaped node structure 3 and the cross-shaped node structure 4 all include a square c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com